Etching equipment for wafers

A technology for etching devices and wafers, applied in the directions of crystal growth, post-processing, chemical instruments and methods, etc., can solve the problems of uneven dripping of etching solution, incomplete etching of wafers, and some holes punched out of wafers, saving manpower, The effect of compact time and avoiding excessive corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail through specific embodiments below.

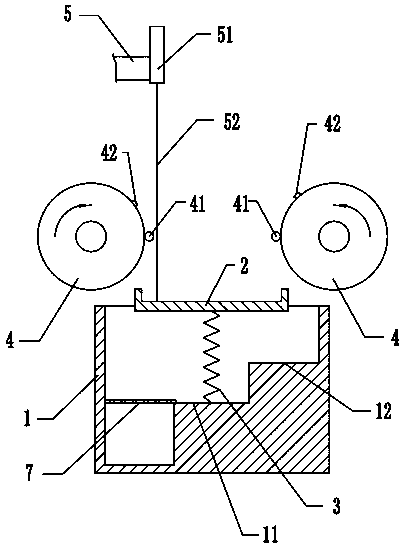

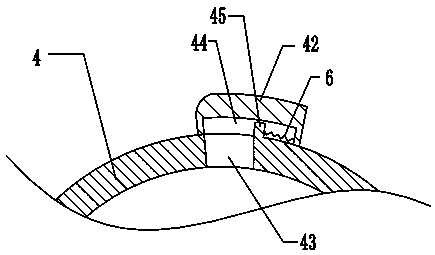

[0021] The reference signs in the accompanying drawings of the specification include: liquid pool 1, tray 2, pressure spring 3, liquid spray roller 4, water inlet 5, extension spring 6, filter screen 7, first-level high platform 11, second-level high platform 12, baffle 41. Cover 42, outlet hole 43, sliding cavity 44, post 45, sliding cover 51, pull cord 52.

[0022] like figure 1 As shown: the water outlet that can flow into clear water for cleaning the wafer is slidably connected to the slide cover 51, the lower end of the slide cover 51 is connected to one end of the stay cord 52, and the other end of the draw cord 52 is connected to one side of the tray 2, and on the side of the tray 2 There is a baffle on the periphery so that the tray 2 can hold the corrosive liquid. The drawstring 52 is in a relaxed state when there is no corrosive liquid in the tray 2. The tray 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com