Self Activated Power Brake

a self-activated, power brake technology, applied in the direction of axially engaging brakes, braking systems, mechanical equipment, etc., can solve the problems of hydraulic pumps or air compressors, increasing and increasing the cost of systems as a whole, so as to achieve the effect of reducing the cost of electric motors and hydraulic pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

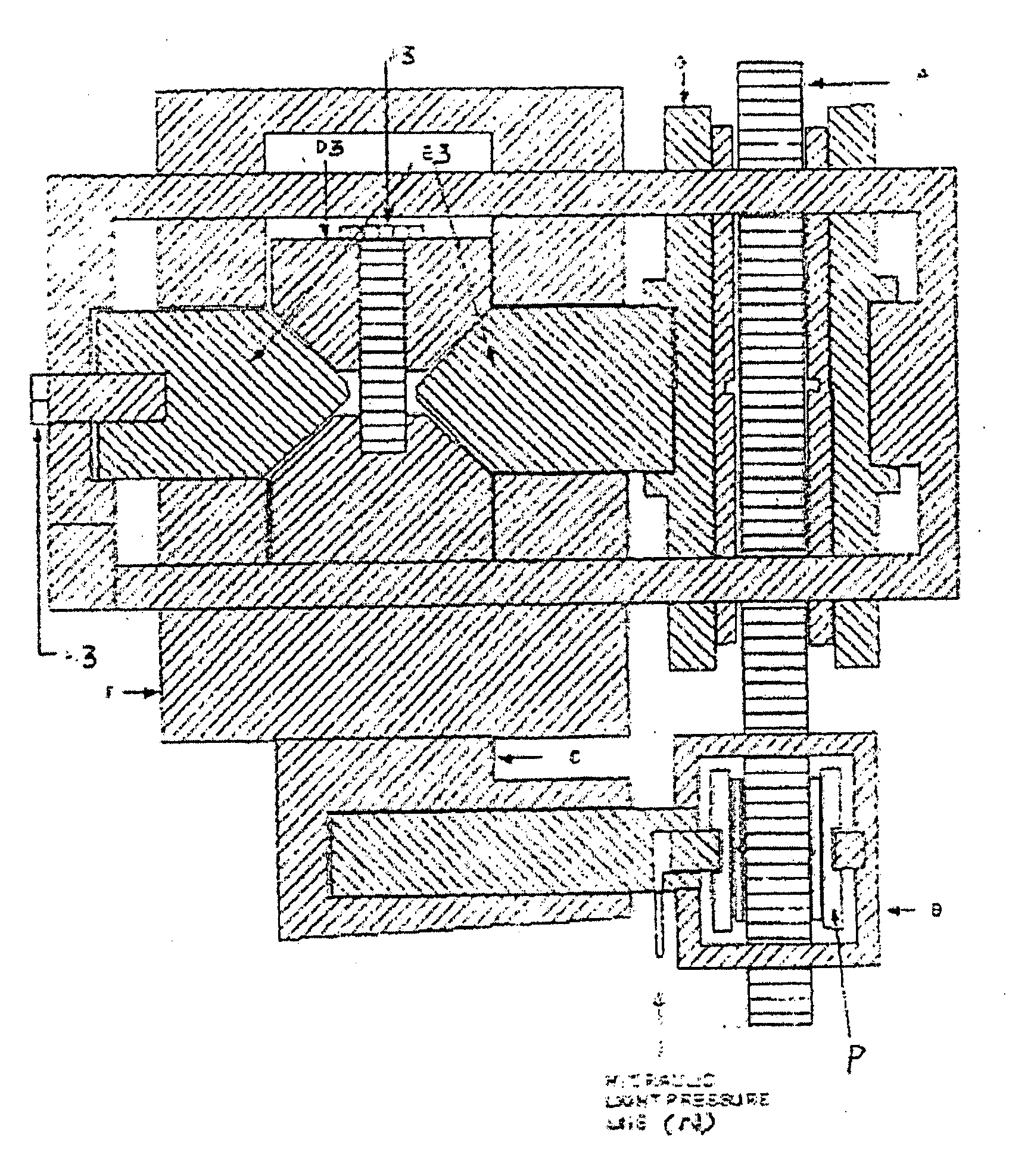

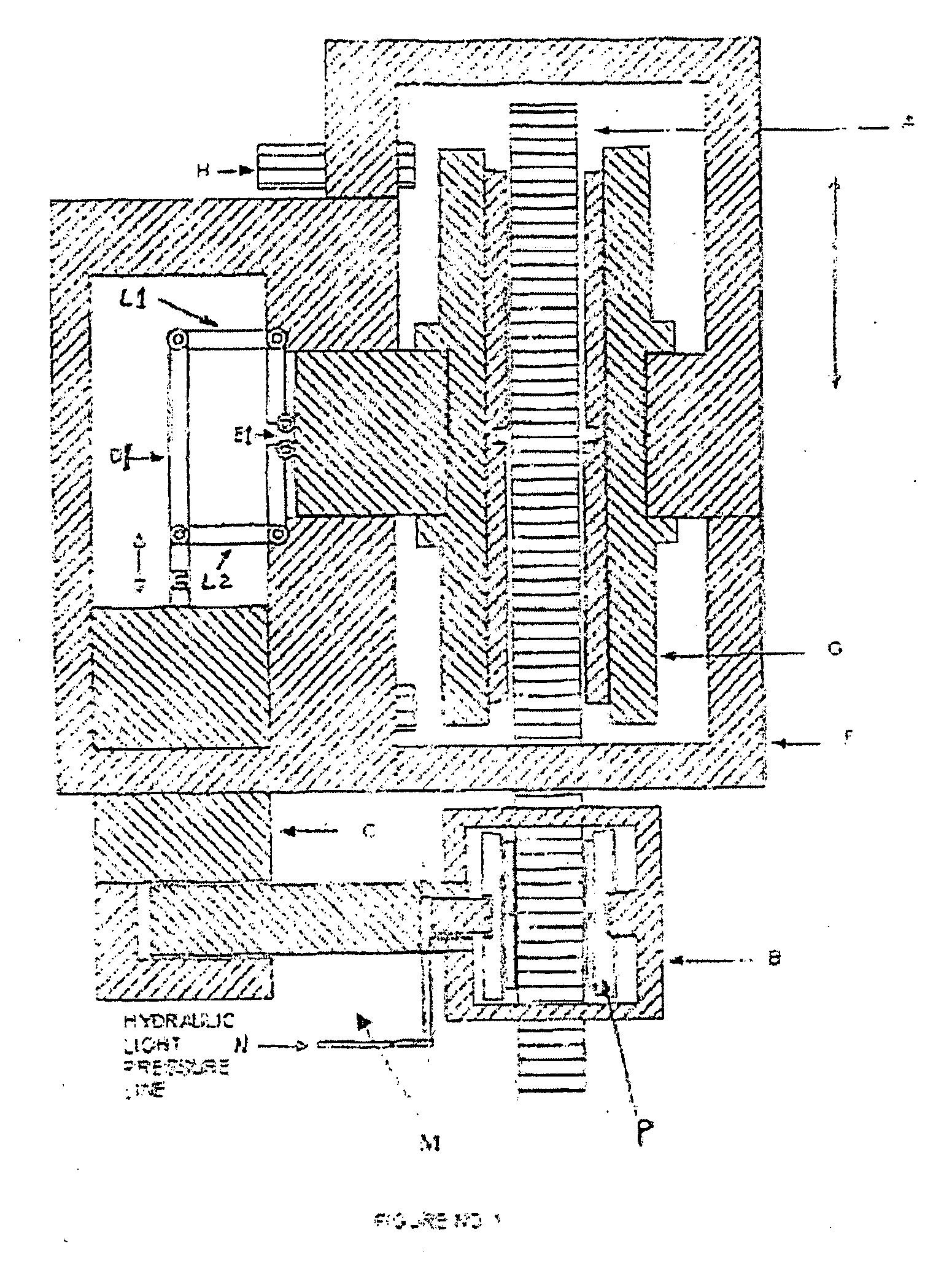

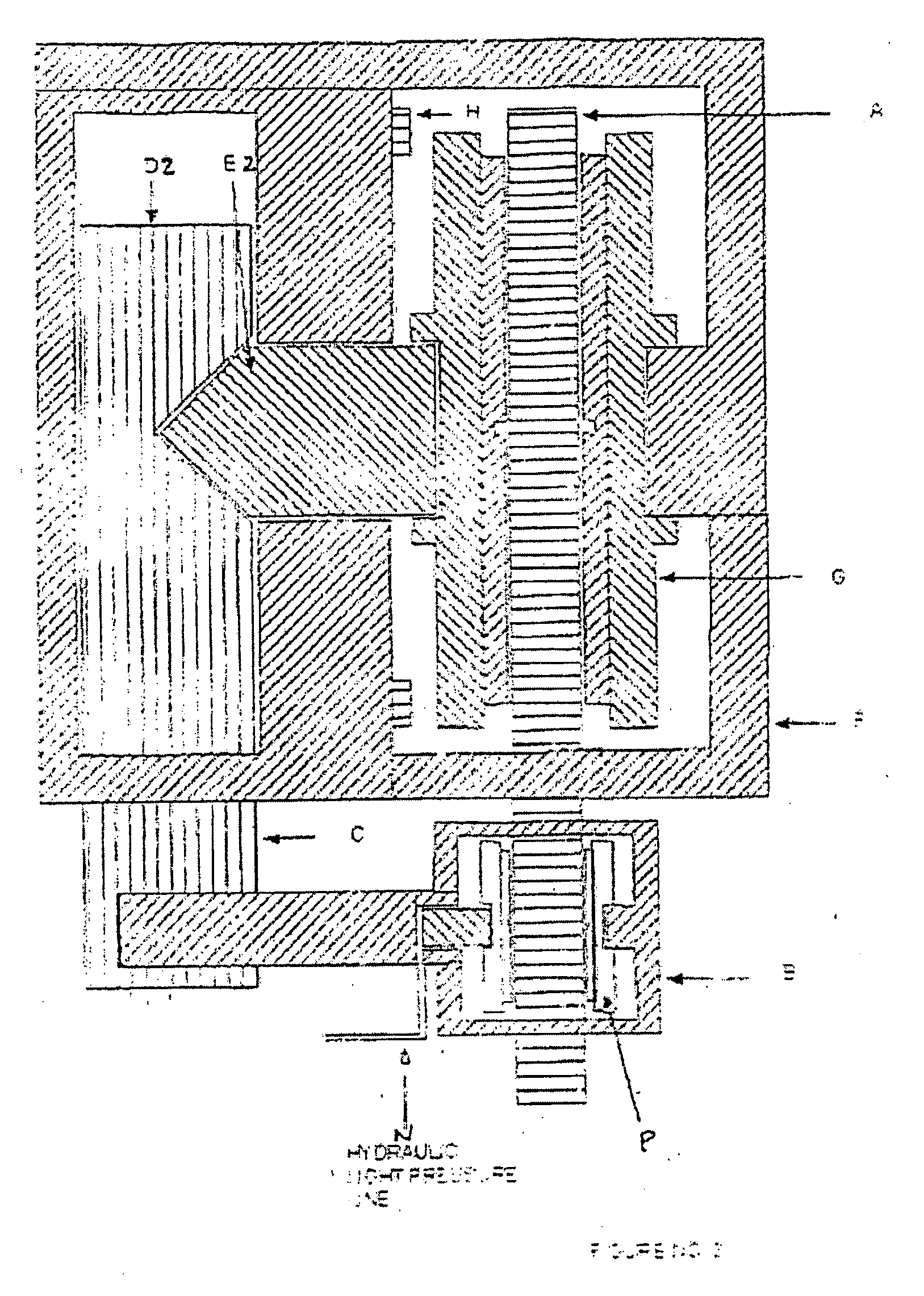

[0034]Referring to the drawings Self Activated Power Brake is made up of a rotating disk / drum (A) coaxially fitted to a wheel (not shown in figures). A housing (F) to hold brake shoes (G) of a brake is provided in a fixed position with respect to said rotating disk. A brake pedal system connected to hydraulic light pressure line (N) to transmit motion generated by hand or feet to at least one actuating pilot caliper (B). Said pilot caliper (B) is attached to preferably one actuating mechanism, which actuates said brake shoes (G). The actuating, mechanism has preferably one linkage mechanism (M) to link said pilot caliper to at least one transmitting means, so that force from the pilot caliper can be transmitted to said transmitting means. Said transmitting means applies force on at least one engaging means, when force is transmitted. Said engaging means, engages said brake shoes (G) to said rotating disk (A) when force is applied. The pilot caliper (B) is made up of at least one eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com