Expander and heat pump using the expander

a technology of expander and expansion pump, which is applied in the field of expansion pump, can solve the problems of inability to recover the energy of expansion of working fluid that passes through the sub-circuit, the inability to control the refrigeration cycle freely, and the inability to efficiently operate the refrigeration cycle, so as to achieve the control of the rotation speed of the expander, the effect of efficient energy recovery of working fluid and high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

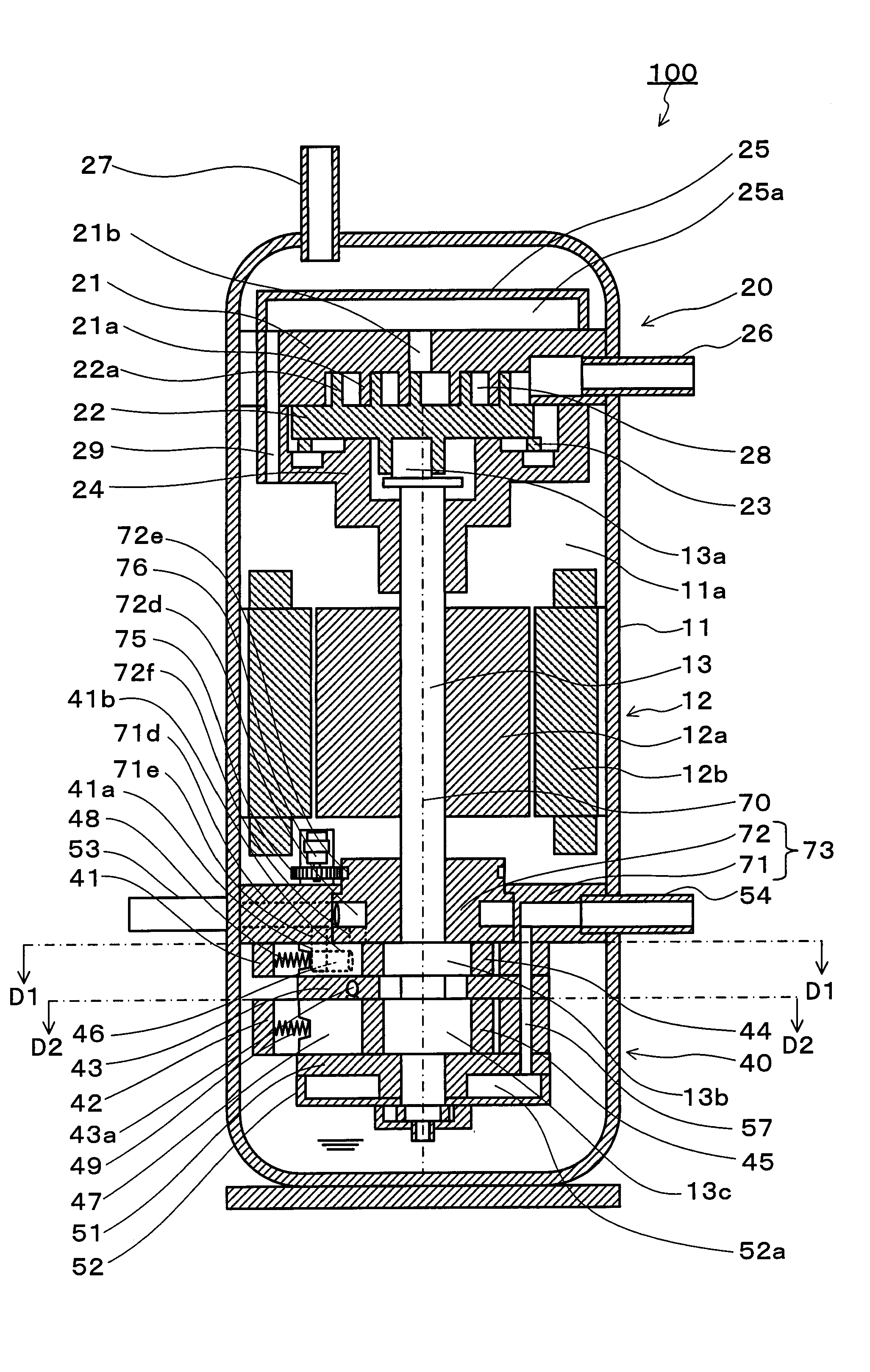

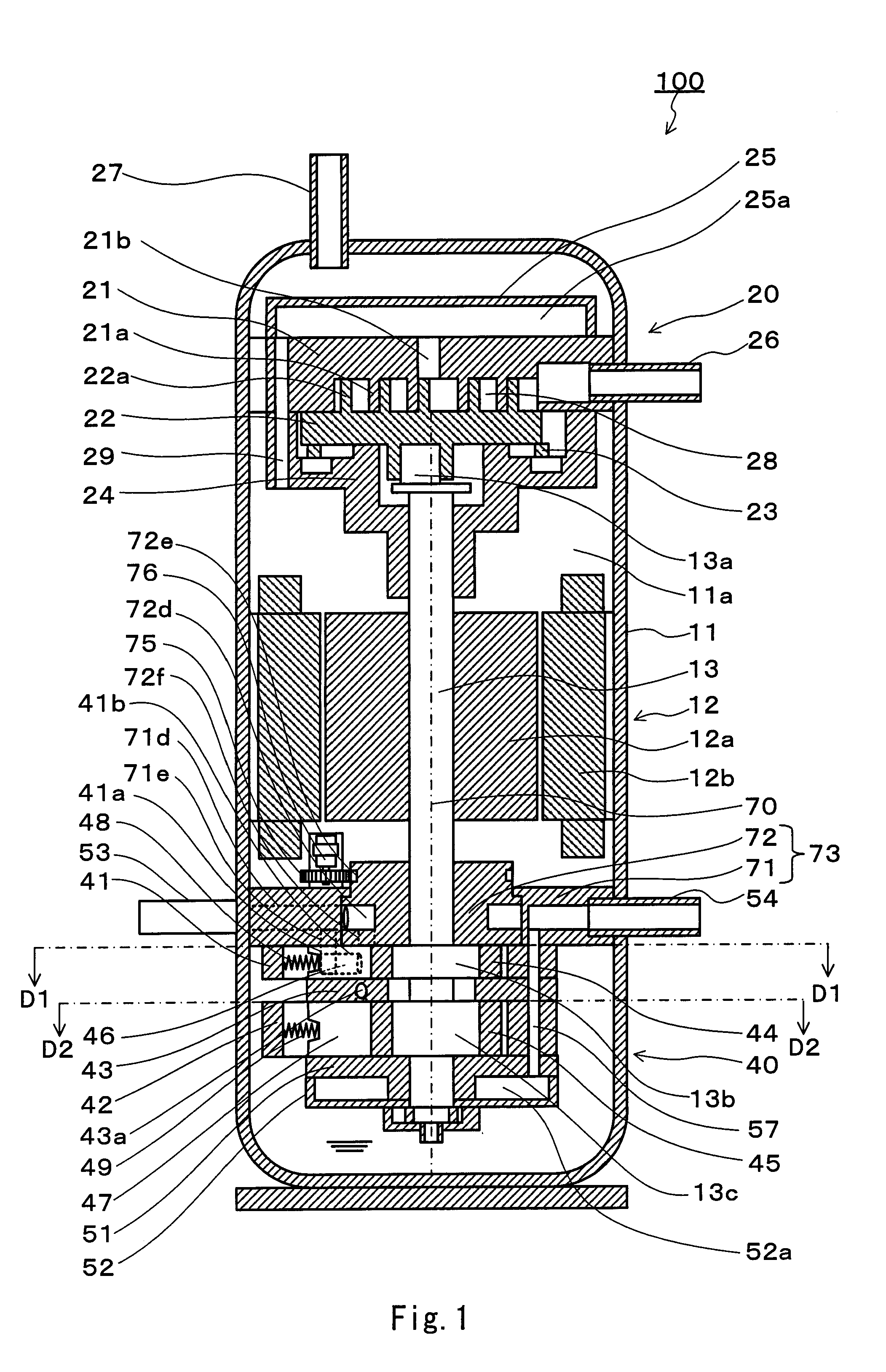

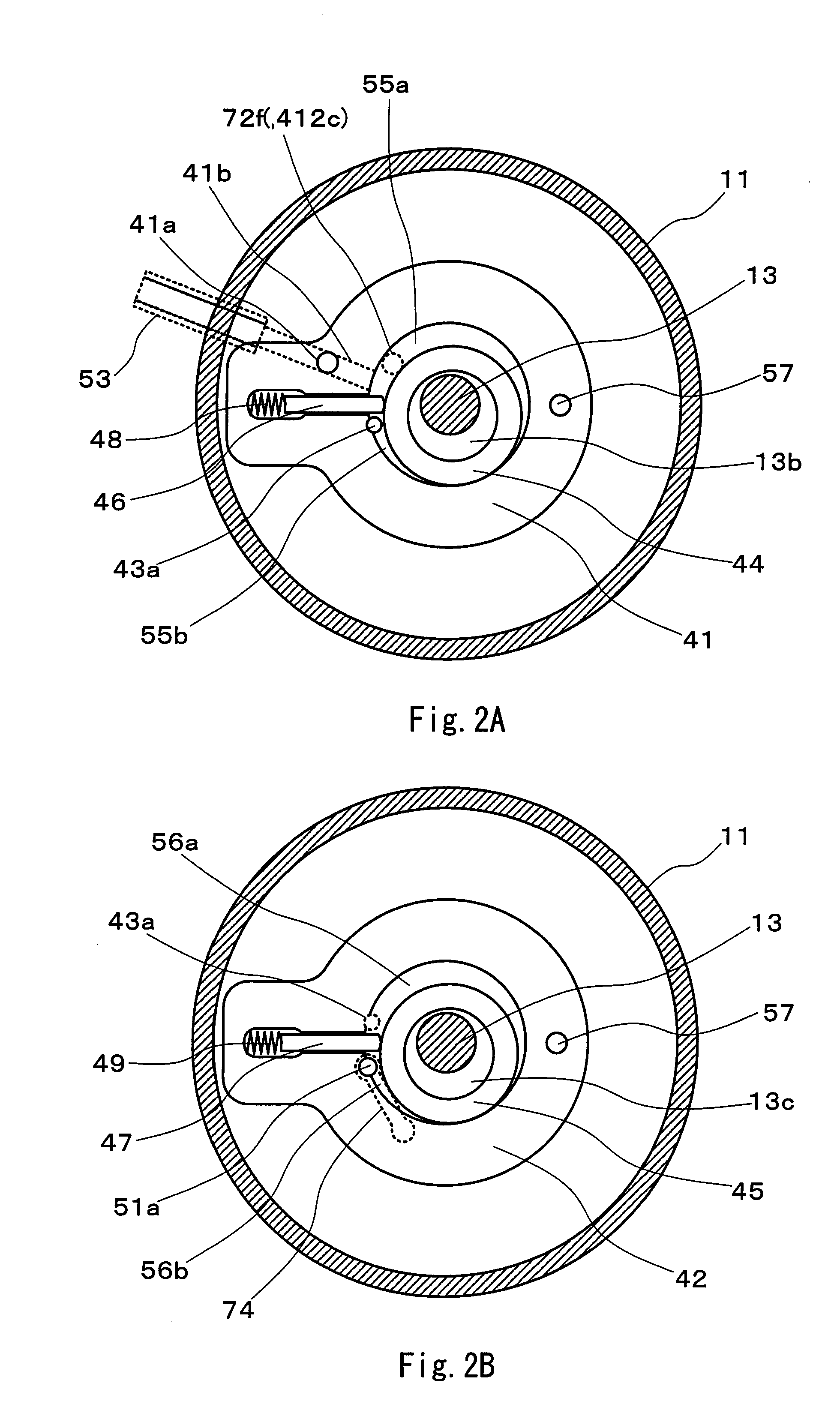

[0055]FIG. 1 is a vertical cross-sectional view illustrating an expander-compressor unit according to a first embodiment of the present invention. FIG. 2A is a horizontal cross-sectional view of an expander section of the expander-compressor unit shown in FIG. 1, taken along line D1-D1 of FIG. 1. FIG. 2B is a horizontal cross-sectional view of the expander section of the expander-compressor unit, taken along line D2-D2. FIG. 3A is a perspective partial cut-away view of a stationary portion of an upper end plate of the expander section. FIG. 3B is a perspective view of a movable portion of the upper end plate. FIG. 3C is a perspective partial cut-away view illustrating the upper end plate in which the stationary portion and the movable portion have been integrated.

[0056]An expander-compressor unit 100 according to the present embodiment includes a closed casing 11, a scroll type compressor section 20 disposed in an upper portion of the closed casing, a two-stage rotary expander secti...

second embodiment

[0100]As has been mentioned in the foregoing embodiment, the position of the second suction port for varying the suction volume of the expander can be varied by an actuator that makes use of pressure difference of a fluid. The actuator making use of pressure difference of a fluid enhances reliability under severe conditions, such as under a high temperature, high pressure environment. Another advantage is that the working fluid that should be expanded by an expander can be utilized as it is for the power source of the actuator. The present embodiment describes a variable suction volume-type expander including such an actuator. In the present embodiment, the same components as described in the first embodiment are designated by the same reference numerals.

[0101]FIG. 11 is a vertical cross-sectional view illustrating an expander according to the second embodiment. As illustrated in FIG. 11, an expander 303 is a rotary type expander. The expander 303 includes a closed casing 11, a powe...

third embodiment

[0142]The features of the expander illustrated in the second embodiment may be employed suitably for an expander-compressor unit in which an expander section and a compressor section are integrated with each other by a shaft, as explained in the first embodiment. FIG. 17 is a vertical cross-sectional view illustrating such an expander-compressor unit.

[0143]An expander-compressor unit 700 includes a closed casing 11, a scroll type compressor section 20 disposed in an upper portion of the closed casing 11, a two-stage rotary expander section 400 disposed in a lower portion of the closed casing 11, a rotation motor 12 disposed between the compressor section 20 and the expander section 400, and a shaft 13 commonly used for the compressor section 20, the expander section 400, and the rotation motor 12. As the rotation motor 12 drives rotation of the shaft 13, the compressor section 20 operates. This expander-compressor unit 700 makes use of the rotational force imparted to the shaft 13 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com