Aboveground Rectangular Secondary Containment Generator Base Tank with Internal Flexible Bladder

a generator base tank and above-ground rectangular technology, applied in the field of storage tanks, can solve the problems of prolonged downtime of the particular device, excessive replacement cost, and steel forming the inner tank can oxidize and/or corrode in storage, and achieve the effect of prolonging corrosion and contaminant resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

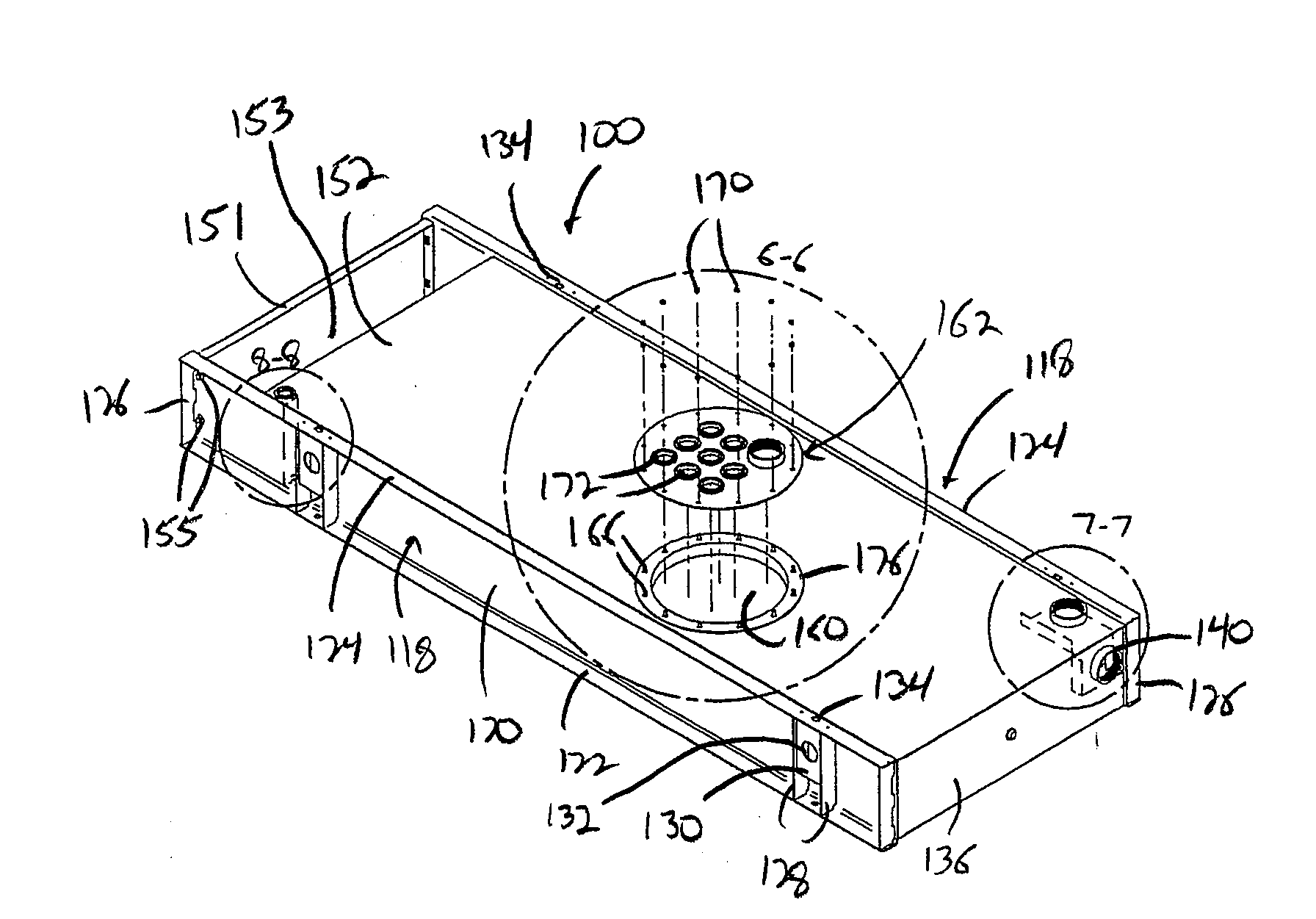

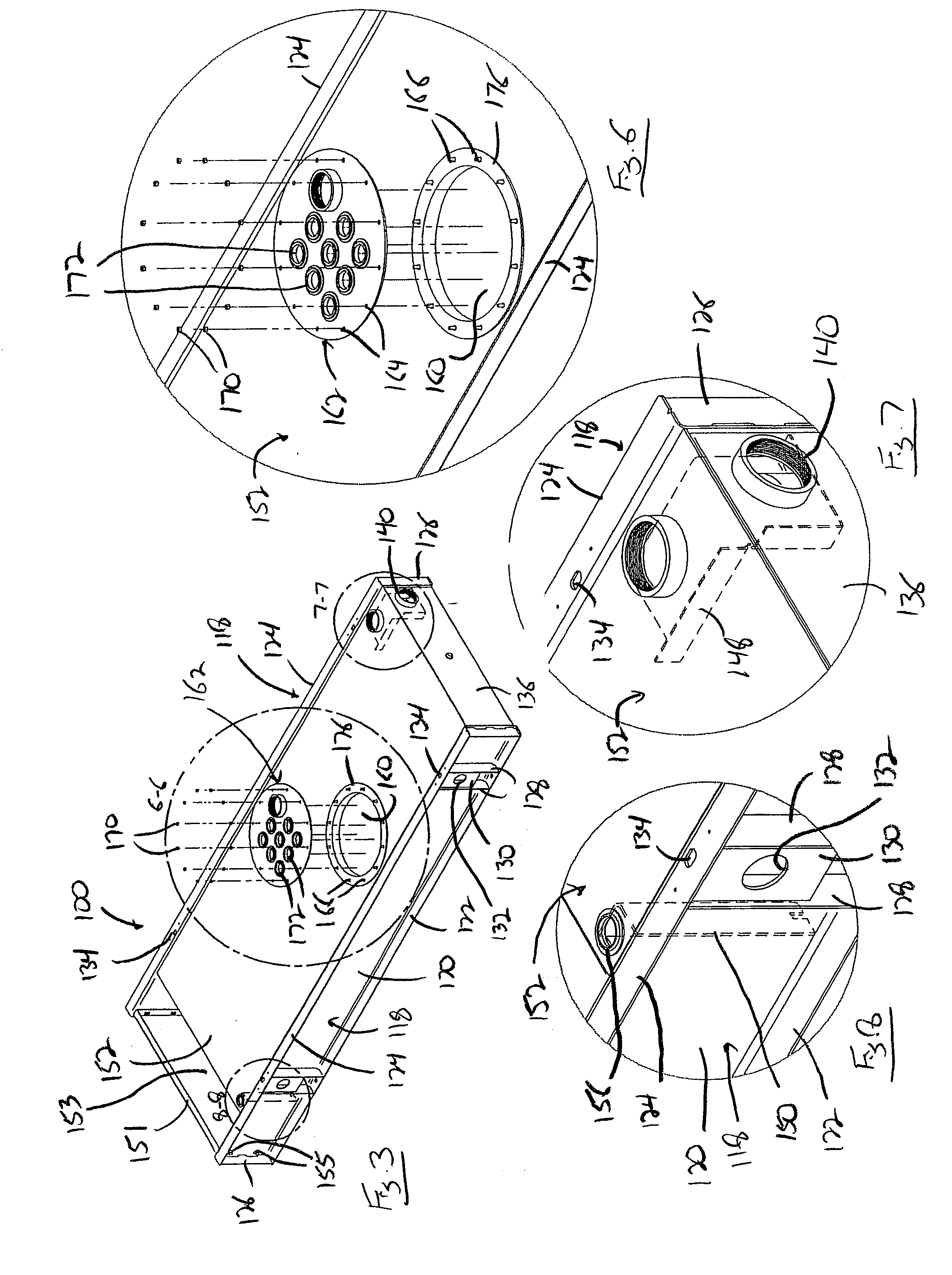

[0023]With reference now to the drawing figures in which like reference numerals designate like parts throughout the disclosure, a containment tank constructed according to the present invention is illustrated generally at 100 in FIG. 3. The tank 100 is constructed similarly to the prior art tank 10 with an inner tank 112 and an outer tank 114. The outer tank 114 that can be utilized in the construction of the container tank 100 can be virtually the same as that used in the prior art tank 10, with a bottom wall 116 and a number of side walls 118 formed from a suitable metal material and secured to one another to form a fluid-tight seal between the respective walls, such as by welding. The side walls 118 each include a central panel 120, a lower flange 122 and an upper flange 124, with the lower flange 122 affixed to the side of the bottom wall 116. The lower flange 122 and the upper flange 124 are joined at each end by an end plate 126, and between the end plates 126 by a number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com