Drying device and sanitary washing apparatus equipped with the same

a technology of sanitary washing apparatus and drying device, which is applied in the direction of water installation, construction, domestic applications, etc., can solve the problems of increasing increasing the cost of the toilet, and increasing the noise of vibration, so as to achieve the effect of enlarging the size of the drying device and efficiently drying in a short tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

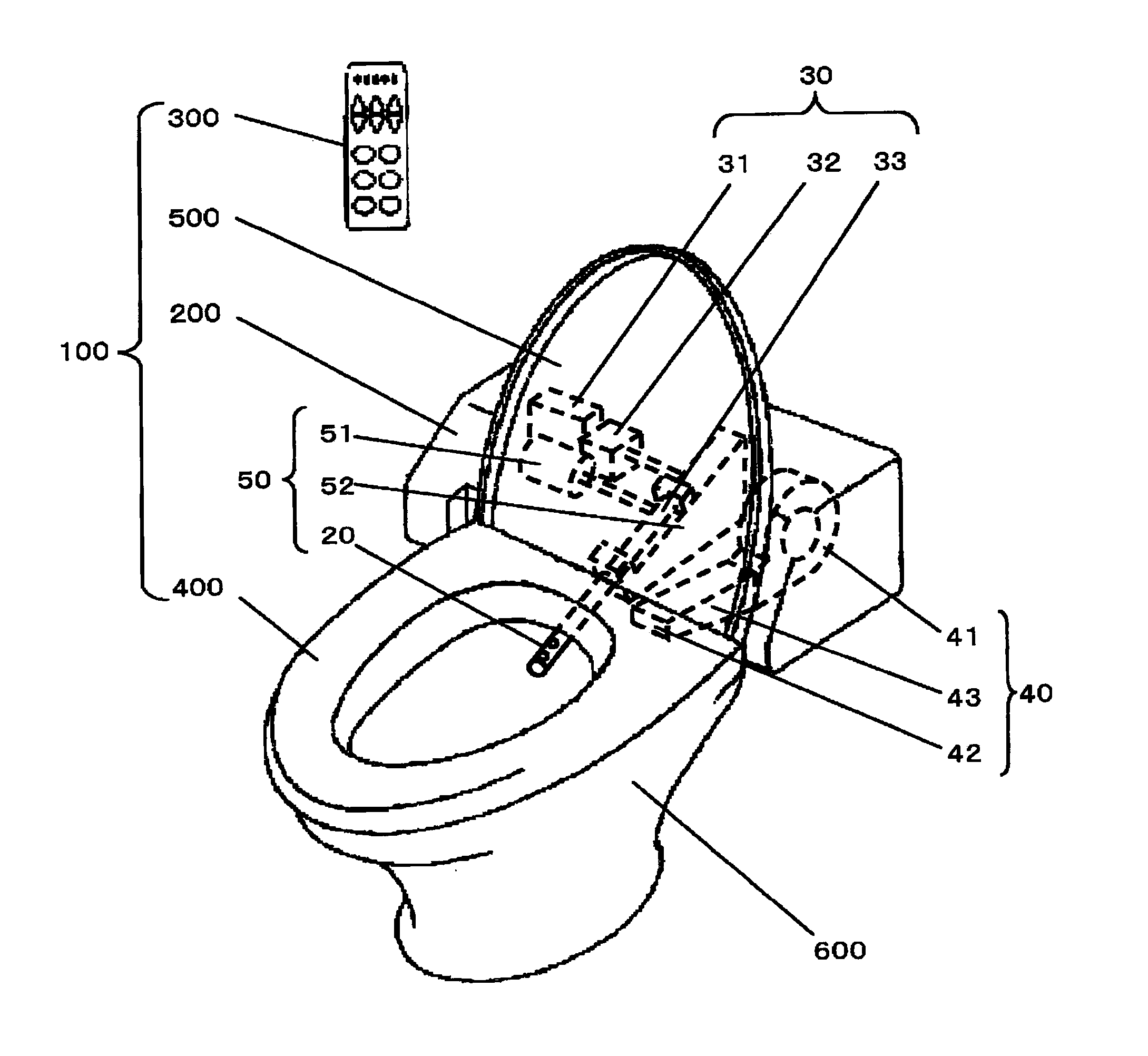

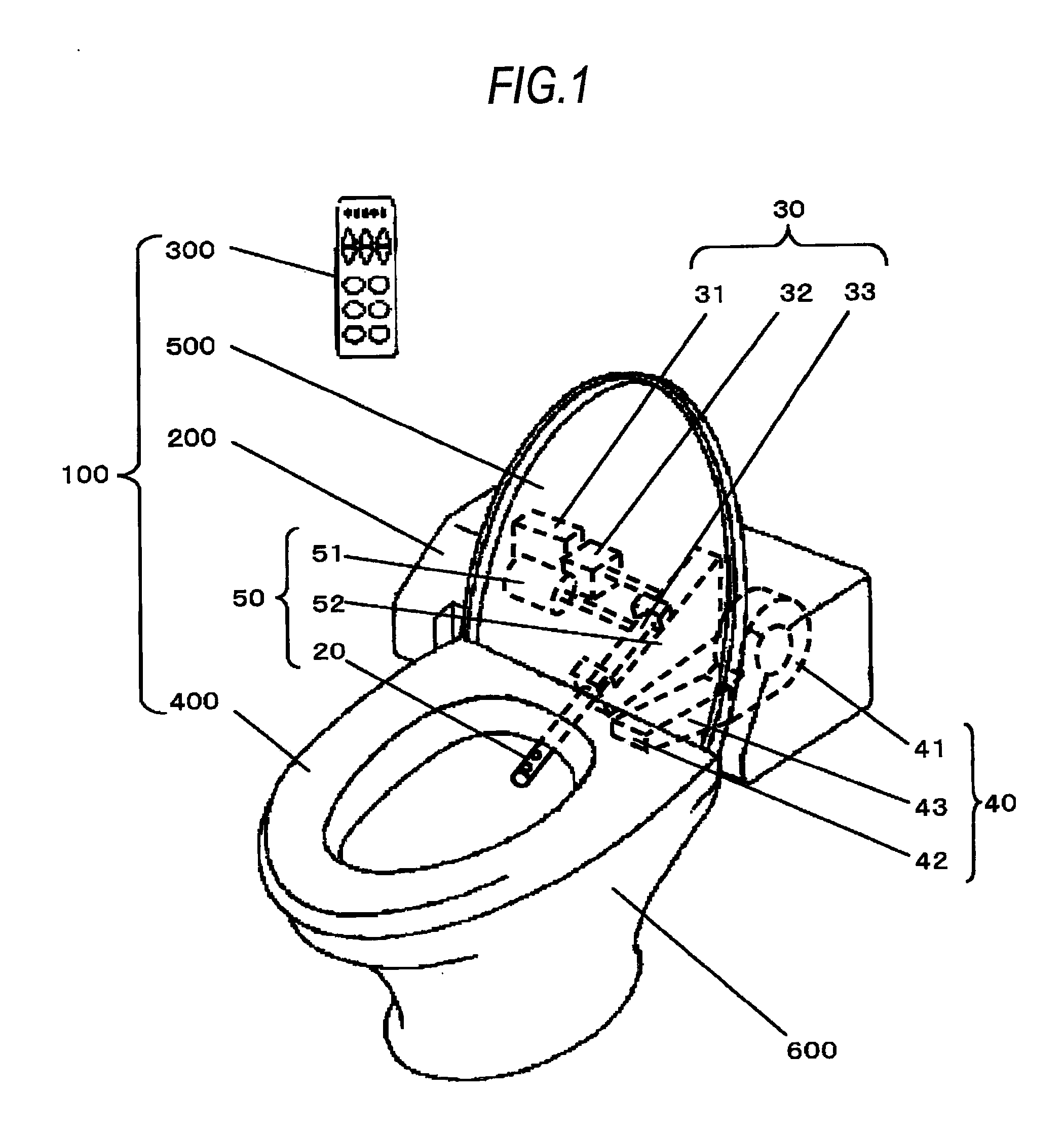

[0145]FIG. 1 is a perspective view illustrating a state in which a sanitary washing apparatus in accordance with an embodiment of the invention is mounted on a toilet bowl.

[0146]As shown in FIG. 1, a sanitary washing apparatus 100 in accordance with an embodiment of the invention is mounted on a toilet bowl 600.

[0147]The sanitary washing apparatus 100 is comprised of a main body 200, a remote control device 300, a toilet seat 400, and a cover 500.

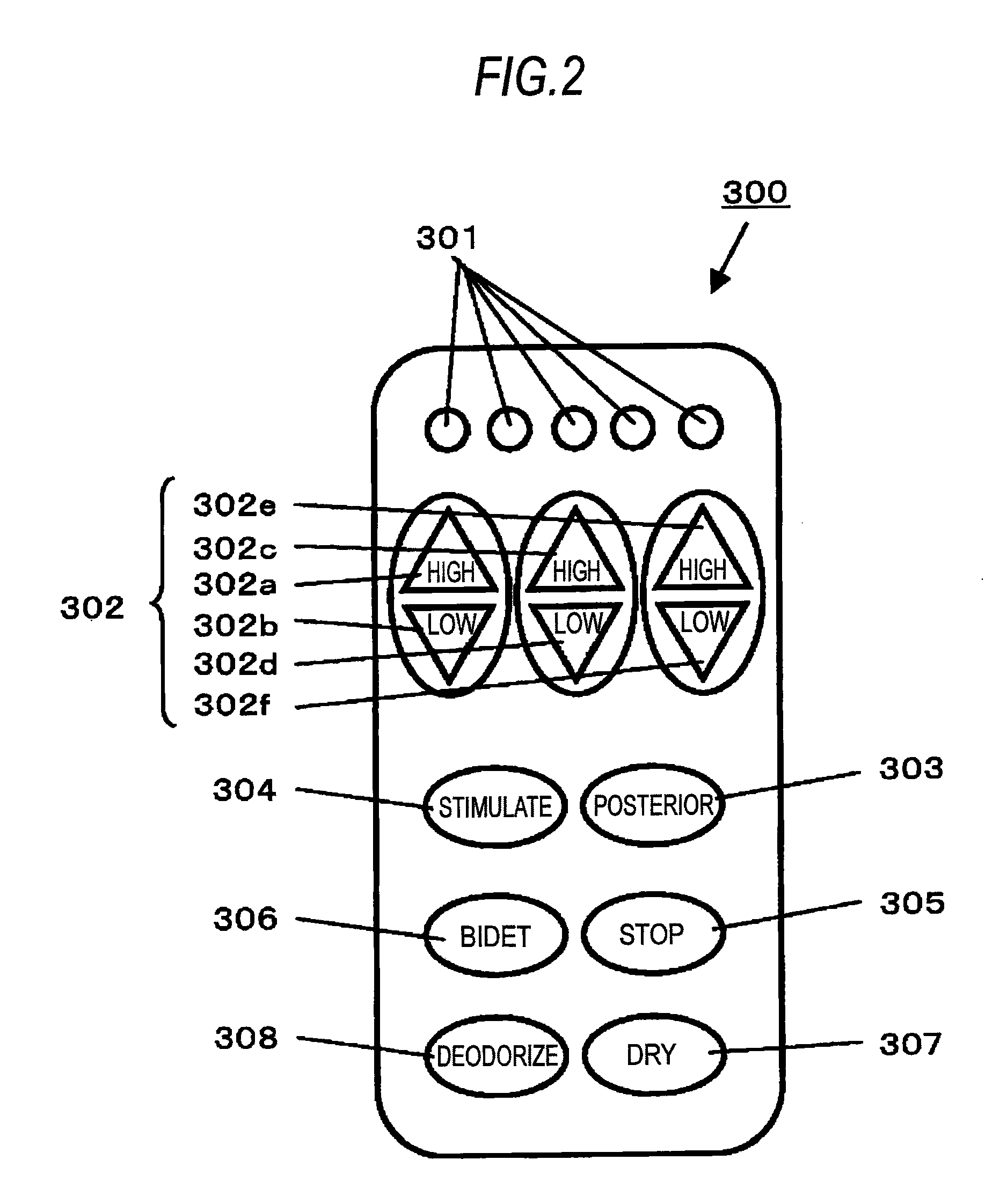

[0148]The toilet seat 400 and the cover 500 are openably attached to the main body 200. Further, the main body 200 is provided with a drying device 50 including a drying nozzle 20 which is an air blowing portion, a washing water spraying unit 30 for spraying washing water, and a heating unit 40, and a controller is incorporated therein. The controller in the main body 200 controls the drying device 50, the heating unit 40, and the washing water spraying unit 30 on the basis of a signal transmitted by the remote control device 300, as will b...

second embodiment

[0208]Next, a description will be given of a sanitary washing apparatus in accordance with a second embodiment of the invention.

[0209]The sanitary washing apparatus in accordance with the second embodiment differs from the sanitary washing apparatus in accordance with the first embodiment in the following aspects.

[0210]FIG. 10 is a partial perspective view of the drying nozzle of the drying device and the swinging device in the sanitary washing apparatus in accordance with the second embodiment of the invention.

[0211]A swinging device 80 shown in FIG. 10 includes a rotating shaft portion 83 connected integrally to a proximal portion 82 of a drying nozzle 81 which is an air blowing portion, a slider 85 for supporting the rotating shaft portion 83 rotatably about an axis 84 of the rotating shaft portion 83, a left-right driving motor 86 for rotating the rotating shaft portion 83, and a gear A 87 and a gear B 88 for transmitting the torque of the left-right driving motor 86 to the rota...

third embodiment

[0216]Next, a description will be given of a sanitary washing apparatus in accordance with a third embodiment of the invention.

[0217]The sanitary washing apparatus in accordance with the third embodiment differs from the sanitary washing apparatus in accordance with the first embodiment in the following aspects.

[0218]FIG. 11 is a timing chart of the controlling operation in “posterior washing” and “drying” operation by the controller of the sanitary washing apparatus. FIG. 12 is a schematic diagram illustrating a moving pattern of the abutment area of the jet of air with respect to the surface to be dried in the state of “drying” operation.

[0219]In the third embodiment, in the meantime from T7 till T13 in FIG. 11, the abutment area E of the jet of air is moved over the outer peripheral portion of the surface F to be dried shown in FIG. 12, sequentially in the order of backward m1, leftward m2, forward m3, rightward m4, and backward m5, and its drive range is thus made to gradually a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com