Lightweight, portable cooking stove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 140

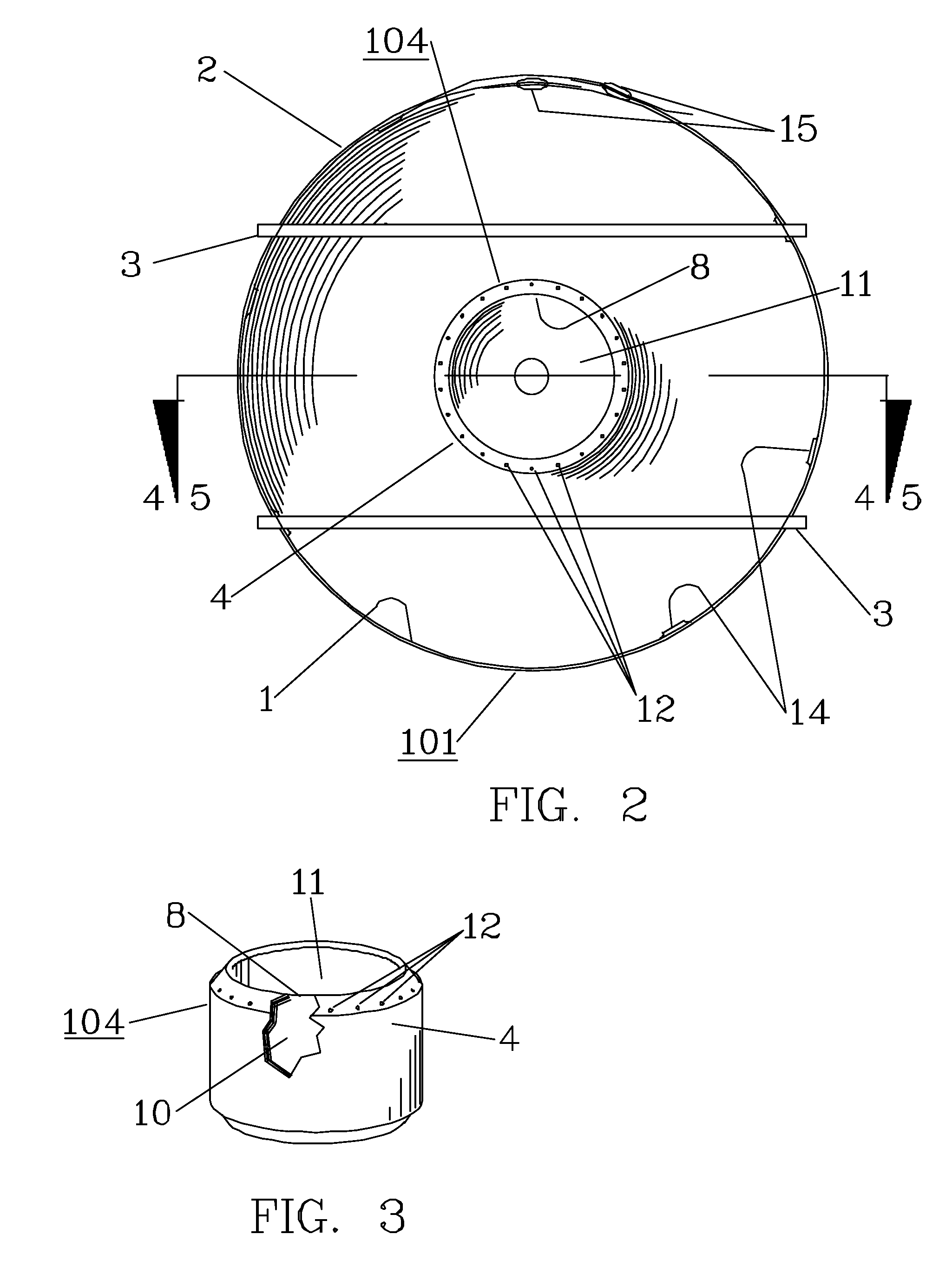

[0117]FIG. 15 shows a perspective view of an alternate embodiment of the fuel vaporizer 140. FIG. 16 shows a cutaway, sectional elevation view of this alternate embodiment 140. The alternate embodiment of the fuel vaporizer 140 is provided with cylindrical duct 53 coaxial with the body of the fuel vaporizer. This cylindrical duct 53 extends thru the center of the fuel vaporizer 140. This cylindrical duct 53 is adapted to provide a source of combustion air to the center of the fuel vaporizer 140. By providing combustion air to the center of the fuel vaporizer 140, complete combustion of the vaporized fuel can be effected.

[0118]The alternate embodiment 140 shares various features with the alternate embodiment 131 of the fuel vaporizer, and operates in a similar manner. The alternate embodiment of the fuel vaporizer 140 comprises a vessel in the shape of a shallow, cylindrical cup 49. This shallow, cylindrical cup 49 incorporates a double wall 50. By means of this double wall 50 the in...

embodiment 180

[0123]FIG. 29 shows a plan view of an alternate embodiment of the fuel vaporizer 180. FIG. 30 shows a cutaway, sectional elevation view of this alternate embodiment 180. The alternate embodiment 180 shares various features with the alternate embodiments 140 and of the fuel vaporizer, and operates in a similar manner. The alternate embodiment of the fuel vaporizer is provided with cylindrical duct 97 coaxial with the body of the fuel vaporizer. This cylindrical duct 97 extends thru the center of the fuel vaporizer 180. This cylindrical duct 97 is adapted to provide a source of combustion air to the center of the fuel vaporizer 180. By providing combustion air to the center of the fuel vaporizer 180, complete combustion of the vaporized fuel can be effected.

[0124]The alternate embodiment of the fuel vaporizer comprises a vessel in the shape of a shallow, cylindrical cup 91. This shallow, cylindrical cup 91 comprises a double wall 98. By means of this double wall 98 the interior volume...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap