Perforated transparent glazing for heat recovery and solar air heating

a technology of perforated transparent glazing and solar air heating, which is applied in the direction of solar radiation prevention, lighting and heating apparatus, heating types, etc., can solve the problems of negatively affecting the overall thermal efficiency of the system, less efficiency of collectors, etc., and achieves the effect of reducing the thermal resistance (insulation) of the back surface, increasing the heat recovery rate, and increasing the solar thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

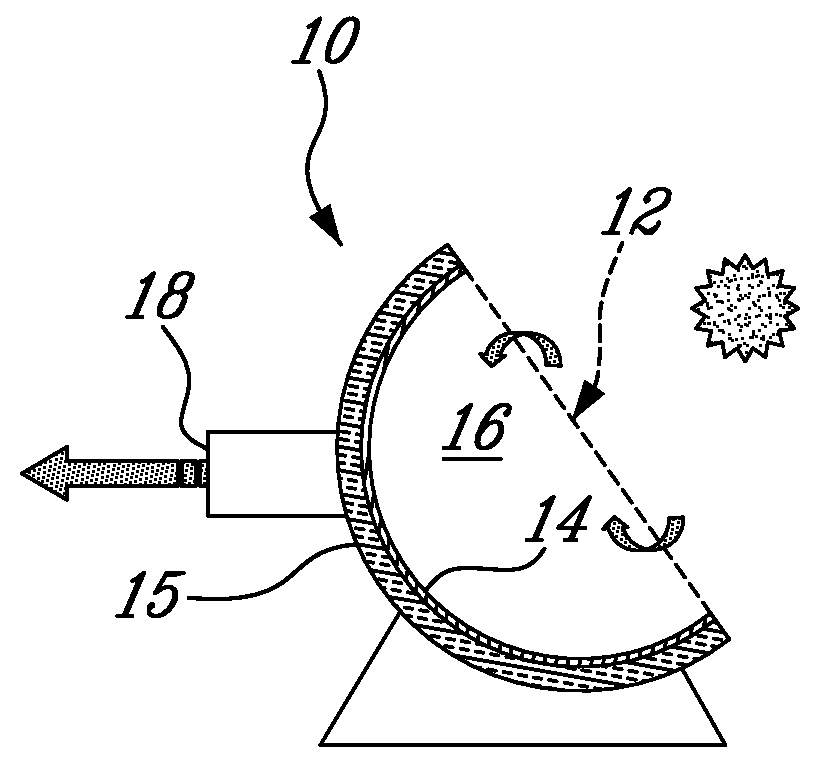

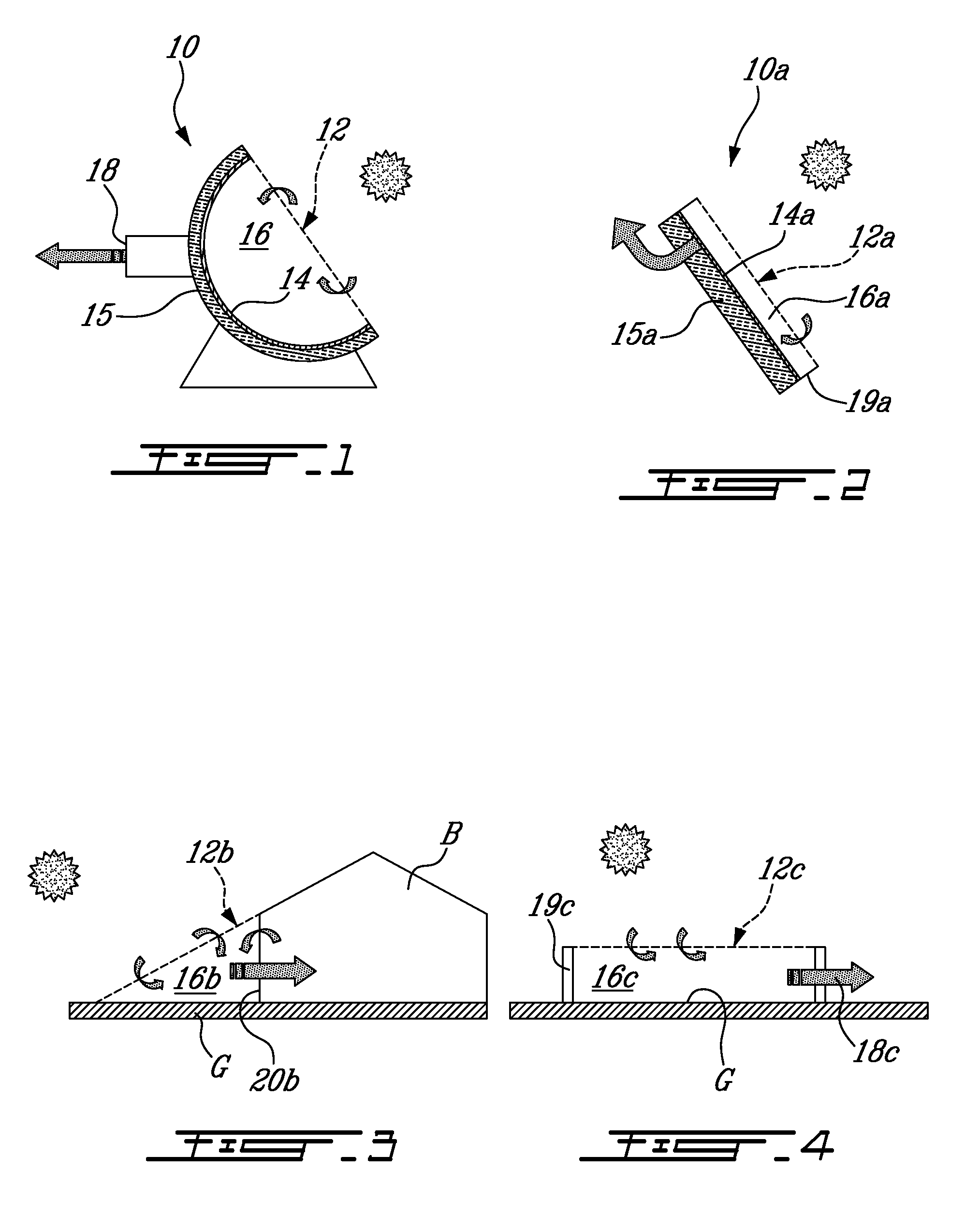

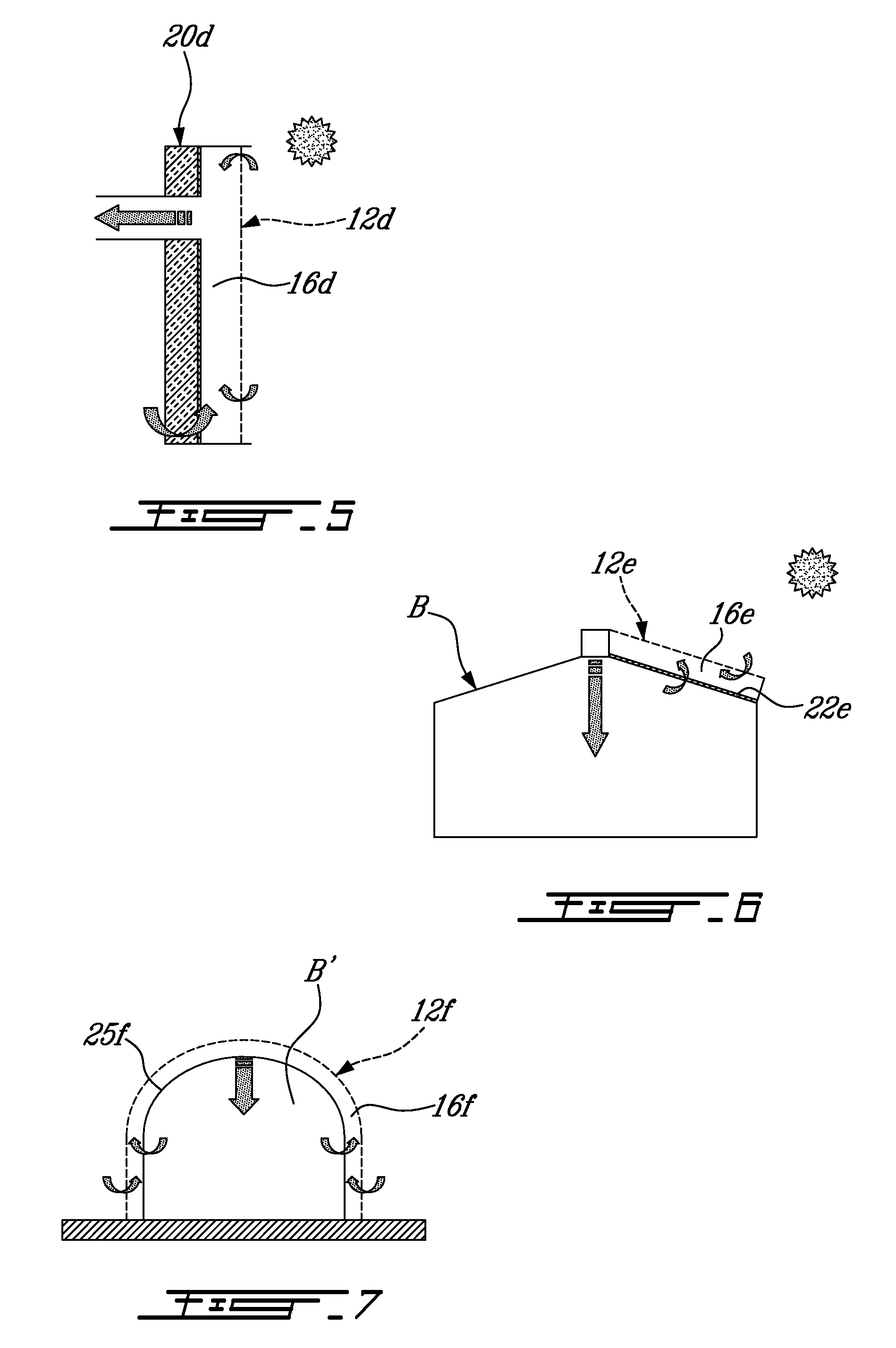

[0019]FIG. 1 shows a solar air heater 10 provided in the form of an elongated conduit-like enclosure mounted on a base and including a sun facing perforated transparent glazing 12 exposed to the ambient and placed in front of a back panel having an arcuate solar radiation absorber plate 14 applied over an insulation layer 15. The back panel is generally provided in the form of a half-pipe wall covered with the perforated transparent glazing 12. The absorber plate 14 can be of a dark color to maximize solar gain. The perforated glazing 12 can be provided in the form of a perforated polycarbonate or transparent UV-resistant plate. Other transparent polymers could be used as well. The glazing 12 can be rigid or flexible. The perforations can be distributed over the entire surface of the glazing or over only a selected surface area thereof. The density of perforations can be uniform or variable over the glazing surface.

[0020]The perforated glazing 12 and the solar radiation absorber pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com