LED assembly with color temperature correction capability

a technology of color temperature correction and led assembly, which is applied in the direction of basic electric elements, electrical apparatus, and semiconductor devices, can solve the problem of significant color temperature shift to the side of high color temperature, and achieve the effect of low cost and easy correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

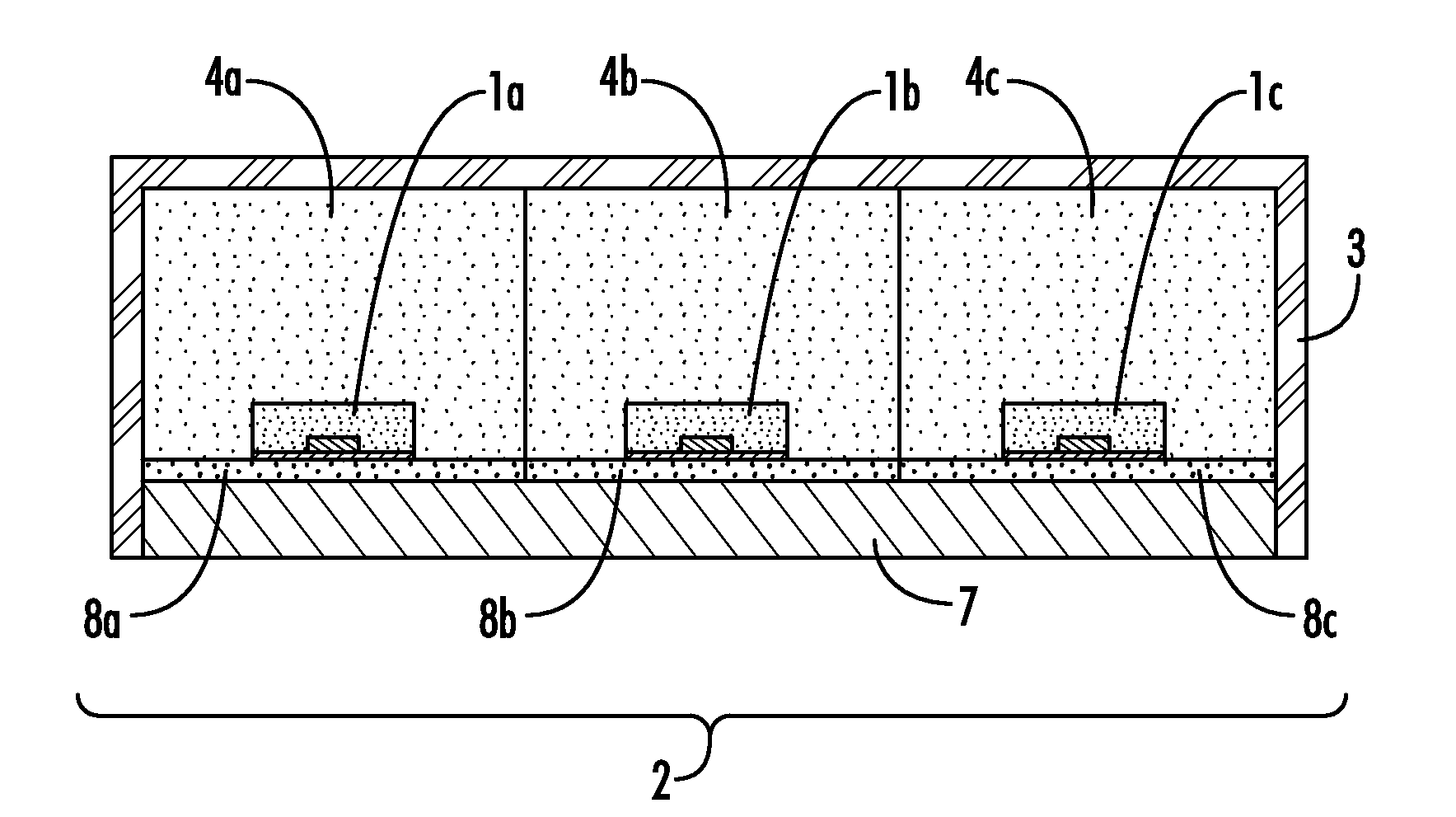

[0037]FIG. 1 shows a structure of a first embodiment of the present invention. As shown in FIG. 1, an illumination device includes a light emitting device 1 such as for example an LED 1, an LED mounting substrate 2 on which the LED is mounted, a case 3 for storing them, and a translucent filling material 4 such as resin 4 (e.g., silicon) for filling the inside of the case 3. The translucent filling material 4 may in fact be entirely transparent in alternative embodiments.

[0038]The LED 1 comprising the light emitting device may be provided with a blue LED chip 5 which emits light with a wavelength of approximately 380 to 480 nm, the blue LED chip sealed with a resin 6 (e.g., silicon) containing a phosphor. One sealing resin 6 may encompass a plurality of LED chips 5.

[0039]The substrate 2 on which the LED 1 is mounted comprises a base material 7, and a coating (ink) 8 applied on the base material 7. The LED 1 and the substrate 2 are embedded and hermetically sealed in the resin 4. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com