Heat exchanger assembly for an aircraft control

a technology of heat exchanger and aircraft control, which is applied in the direction of lighting and heating apparatus, machine operation mode, heating type, etc., can solve the problems of large temperature swings experienced by the fadec, inconvenient to the best performance of these temperature sensitive components, and require a substantial amount of cooling to limit the operating temperature of the fad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

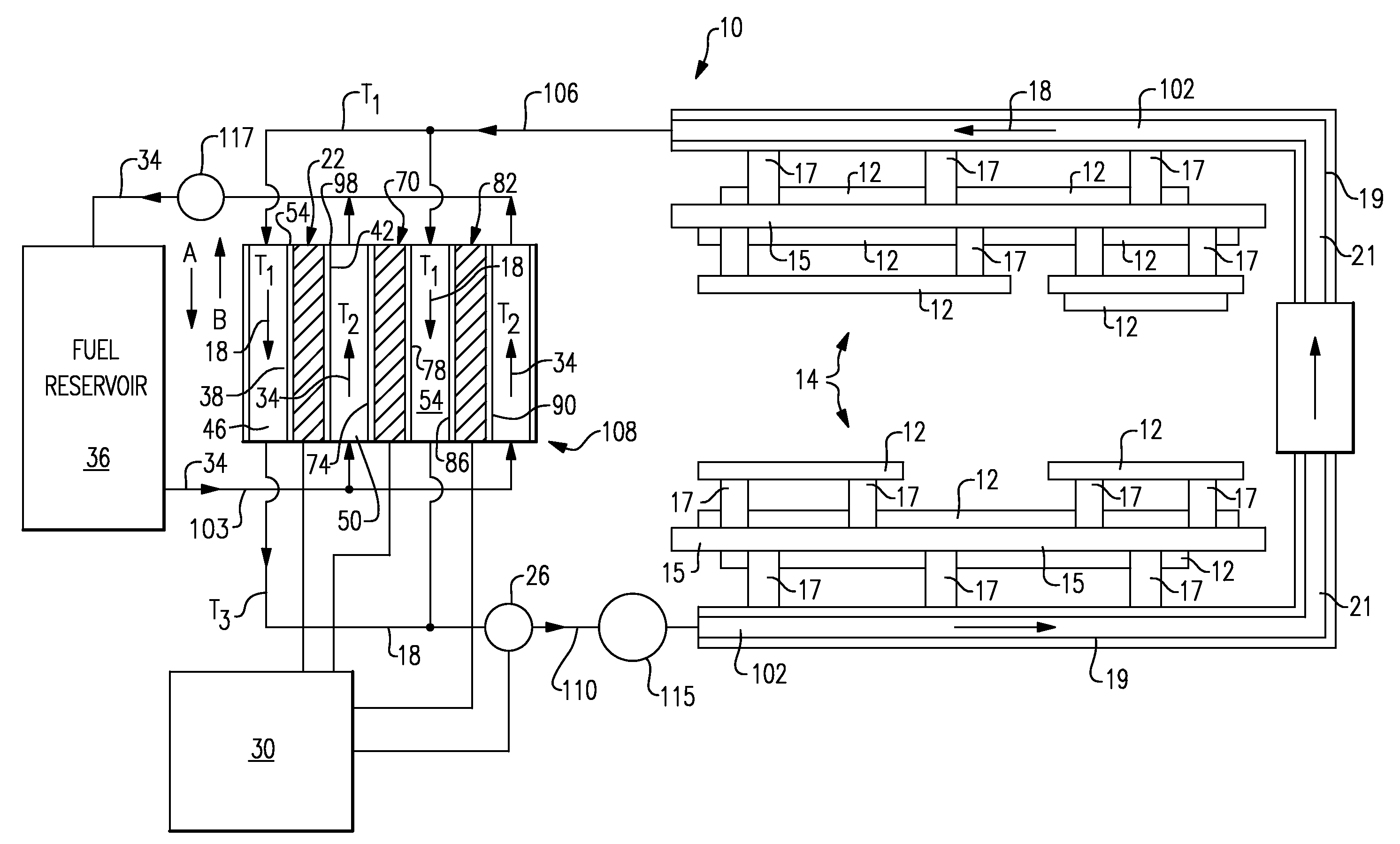

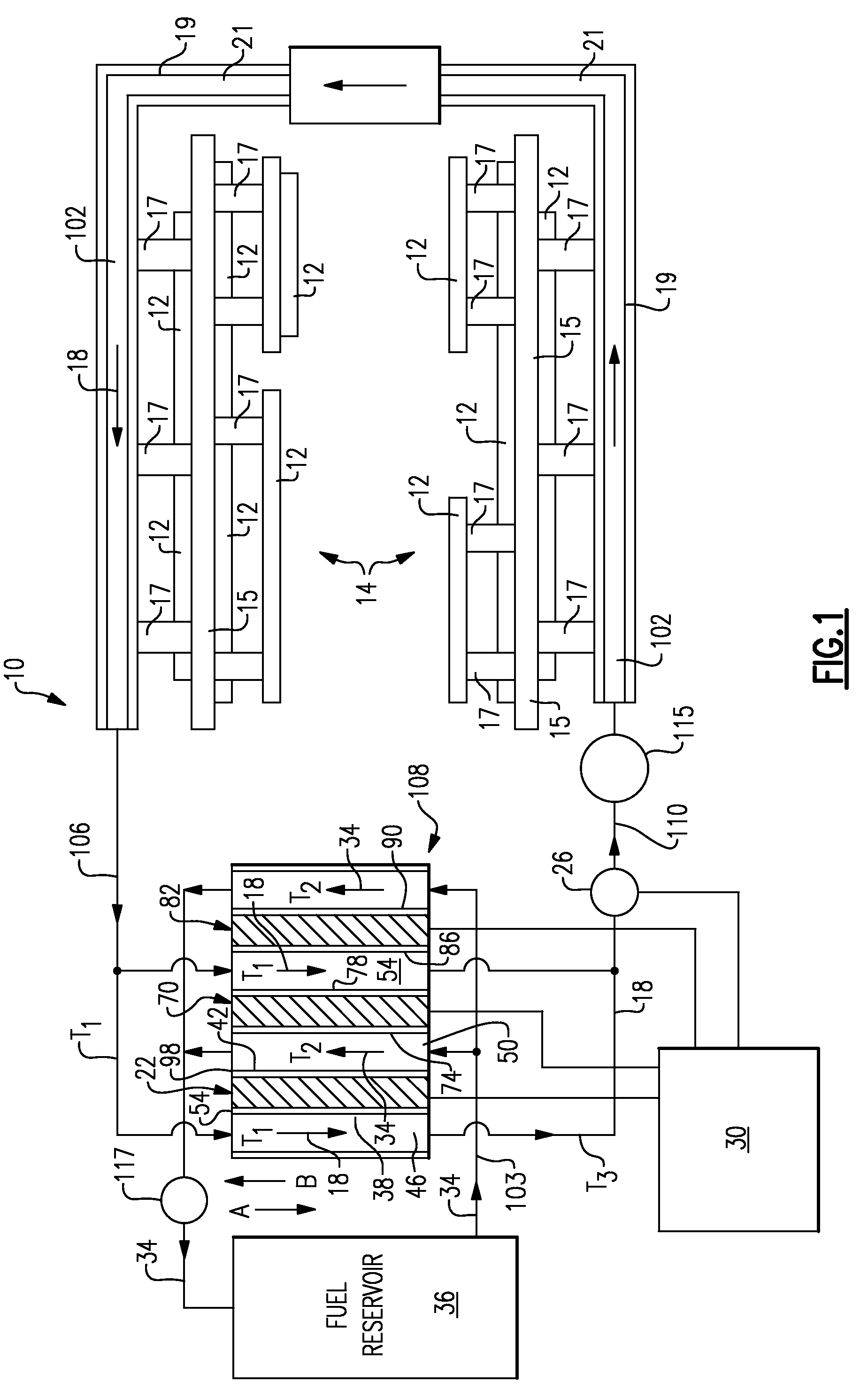

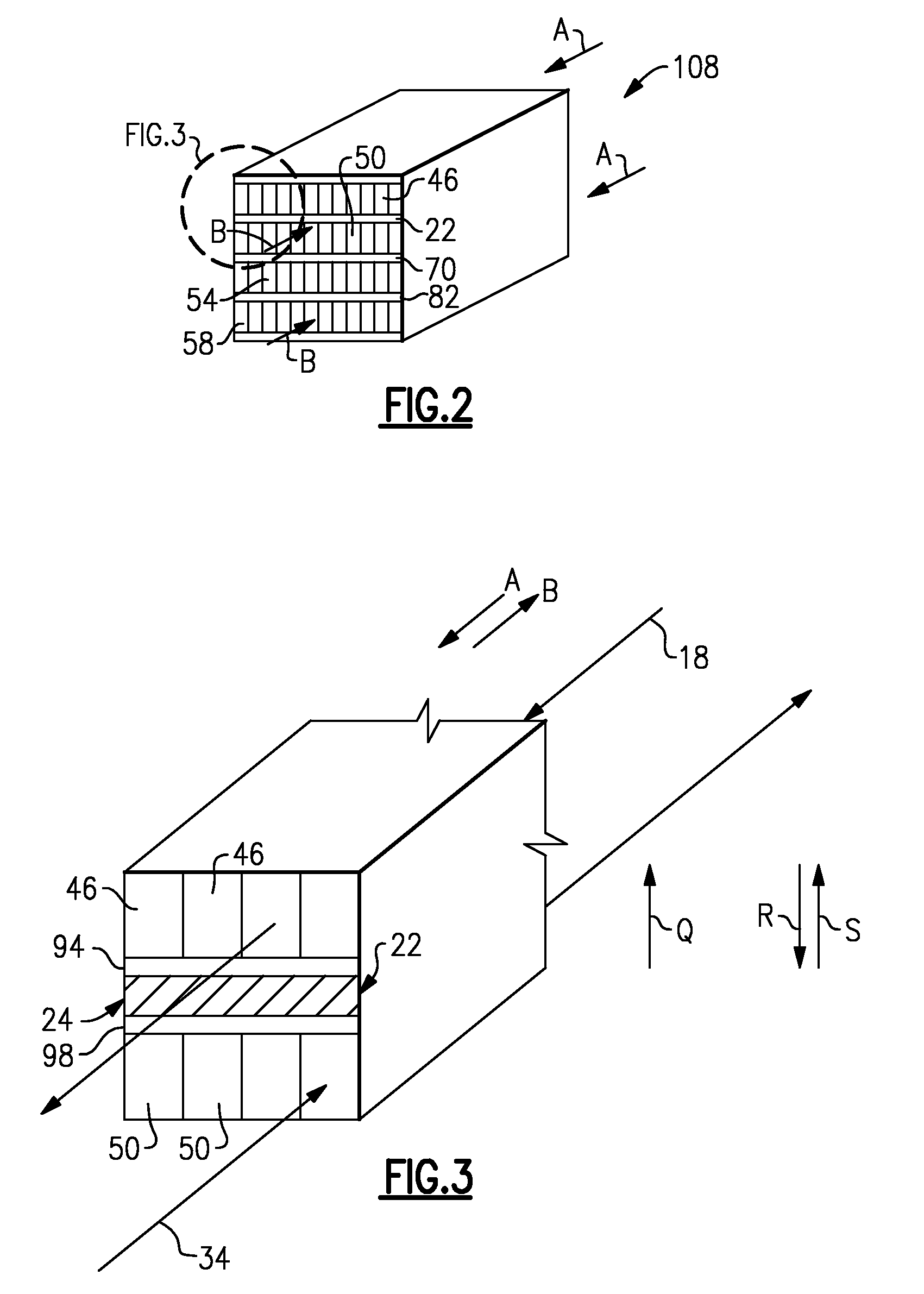

[0011]In FIG. 1 there is shown heat exchanger assembly 10 for aircraft control 14. FIG. 1 is a schematic and shows the general operation of heat exchanger assembly 10. As shown, aircraft control 14, such as a FADEC, for example, is composed of printed circuit boards 12. Printed circuit boards 12 are mounted to frame 19 in a tiered fashion. Printed circuit boards 12 are mounted to heat sinks 15 and conduction posts 17, which are all mounted to frame 19. This arrangement permits heat to be transferred between printed circuit boards 12 and frame 19.

[0012]Frame 19 has first fluid 18 to act as a heat exchanger for printed circuit boards 12 through heat sinks 15 and heat conduction posts 17. In this regard, first fluid 18 may be any of a variety of fluids, including aircraft engine fuel, ethylene glycol or any antifreeze. Frame 19 has fluid channel 21, an internal conduit that allows the circulation of first fluid 18 via pump 115 to thermoelectric assembly 108 and back to frame 19. First ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com