Compressor blade leading edge shim and related method

a technology of compressor blades and leading edges, applied in the field of turbine technology, can solve the problems of high cost of repair and/or replacement of damaged turbine blades, high cost of replacement, and high cost of turbine blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

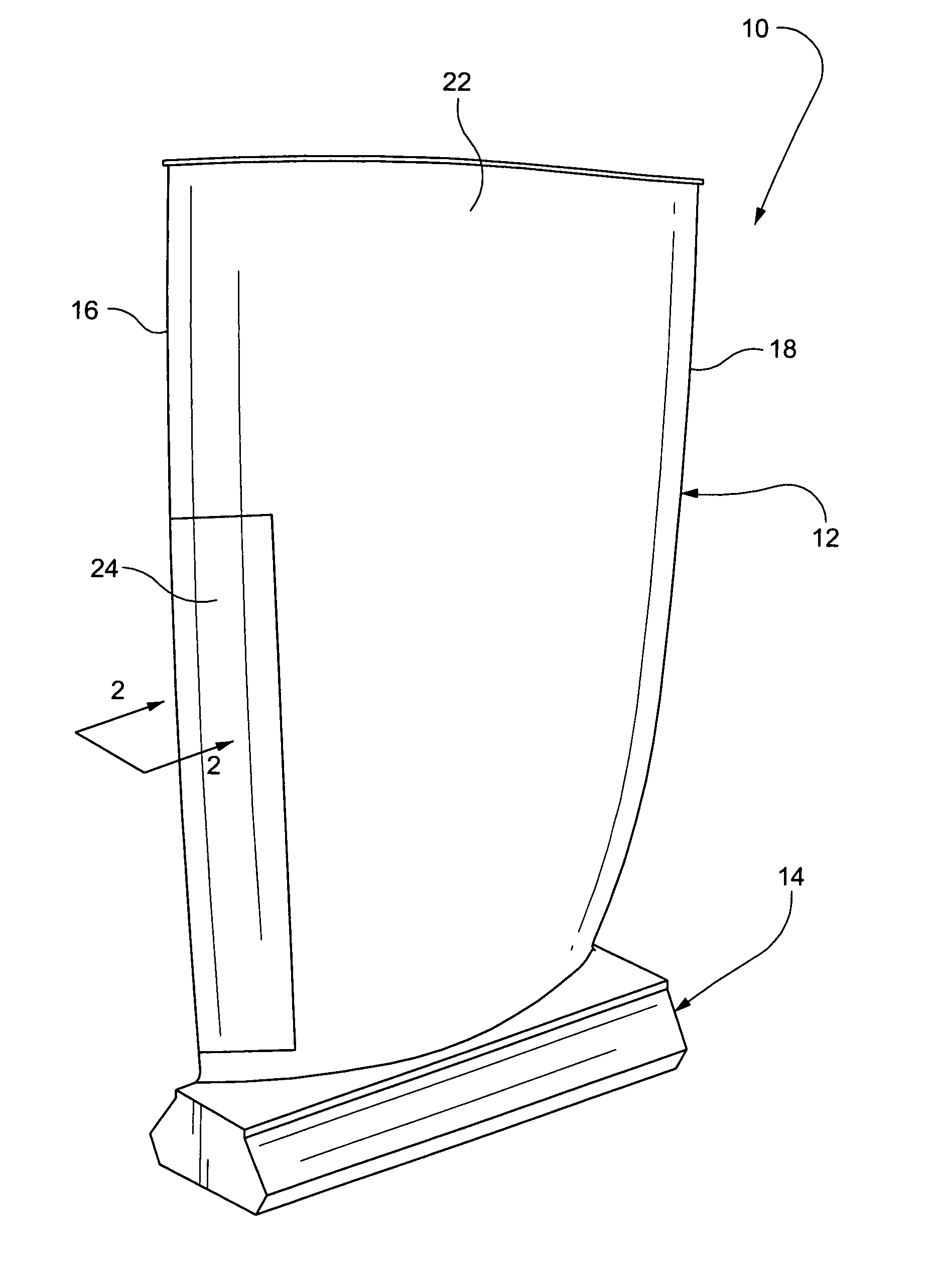

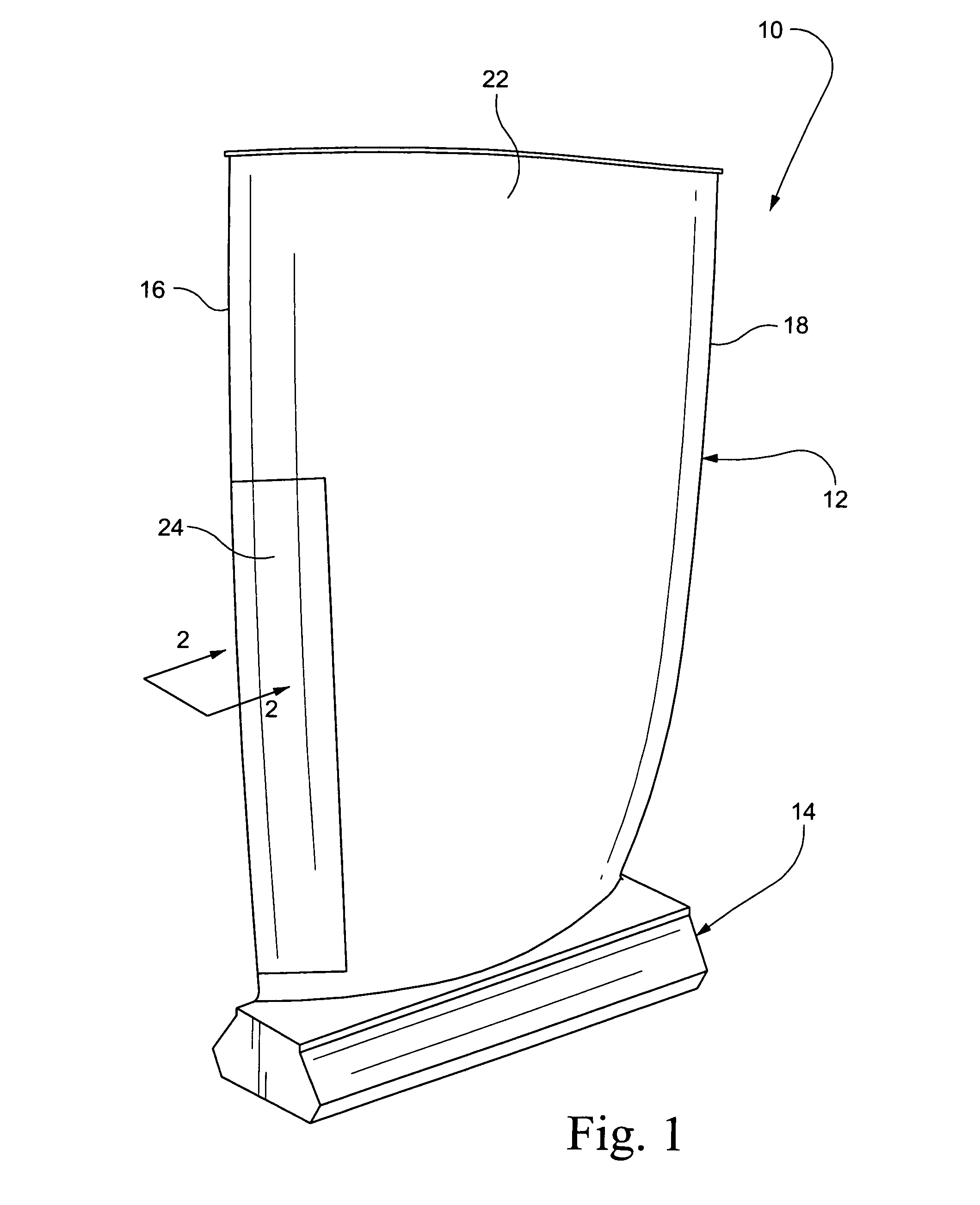

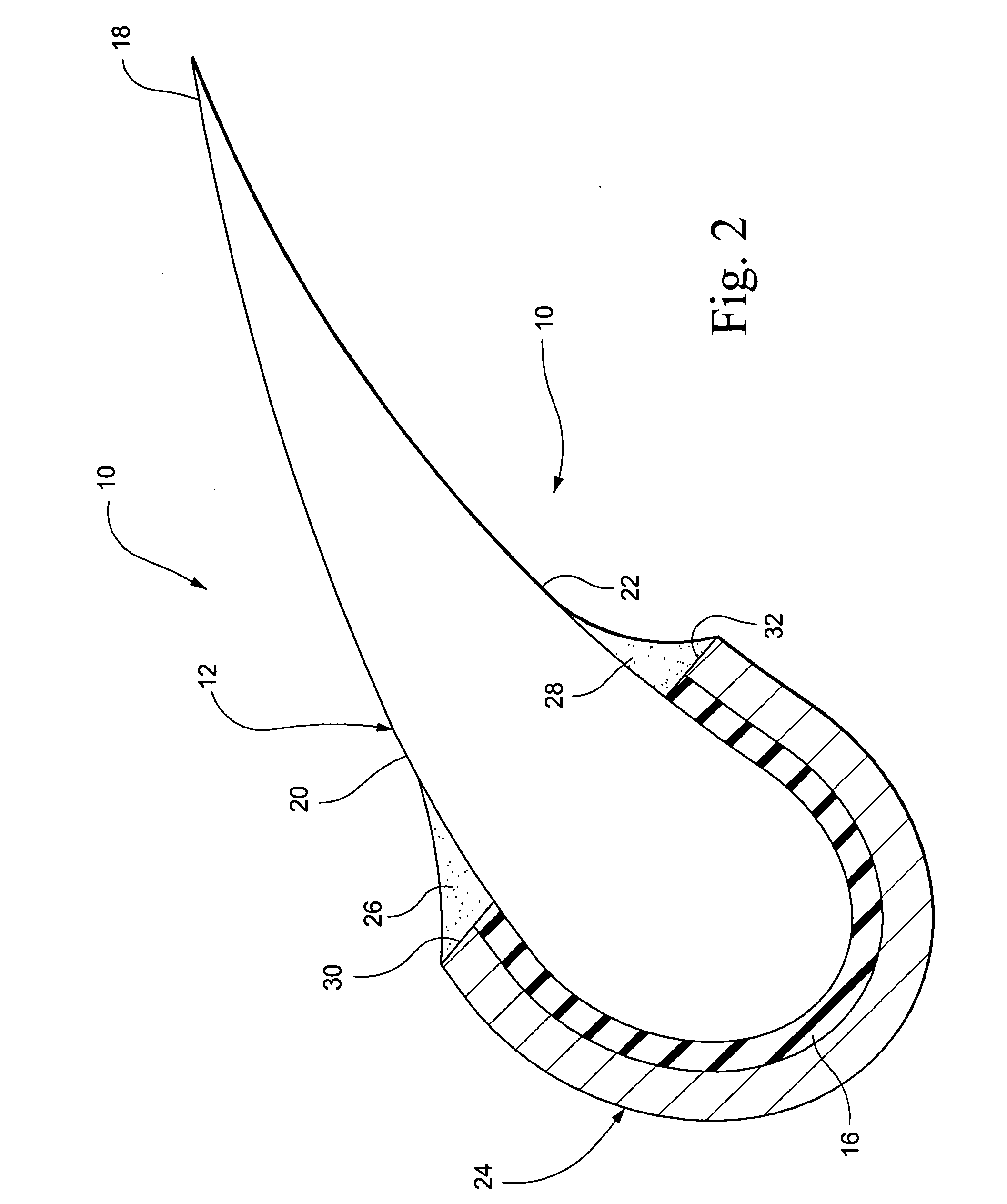

[0009]With reference to FIG. 1, a vane or blade 10, e.g., a turbine compressor blade, includes an airfoil portion 12 and a dovetail mounting portion 14. The airfoil portion 12 has a leading edge 16, a trailing edge 18, a pressure side 20 and a suction side 22.

[0010]It is the leading edge 16 that is most susceptible to erosion and / or corrosion due to incoming air flow (containing, for example, dry particles, salt fog, etc.) at the compressor inlet.

[0011]In accordance with a non-limiting exemplary embodiment of this invention, one or more shims 24 may be applied to the leading edge 16 of the airfoil portion. With further reference to FIG. 2, the shim 24 substantially encloses the leading edge 16, extending into both the pressure and suction sides 20, 22 of the airfoil. Note that in FIG. 2, the shim is shown in greatly exaggerated scale simply to facilitate an understanding of the invention. One shim may extend along part or substantially the entire length of the leading edge, or alter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com