Molding of die-cast product and method of

a technology of die-cast products and molds, applied in the direction of molten metal supply equipment, melt-holding vessels, manufacturing tools, etc., can solve the problems of die-cast products that are prone to surface imperfections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

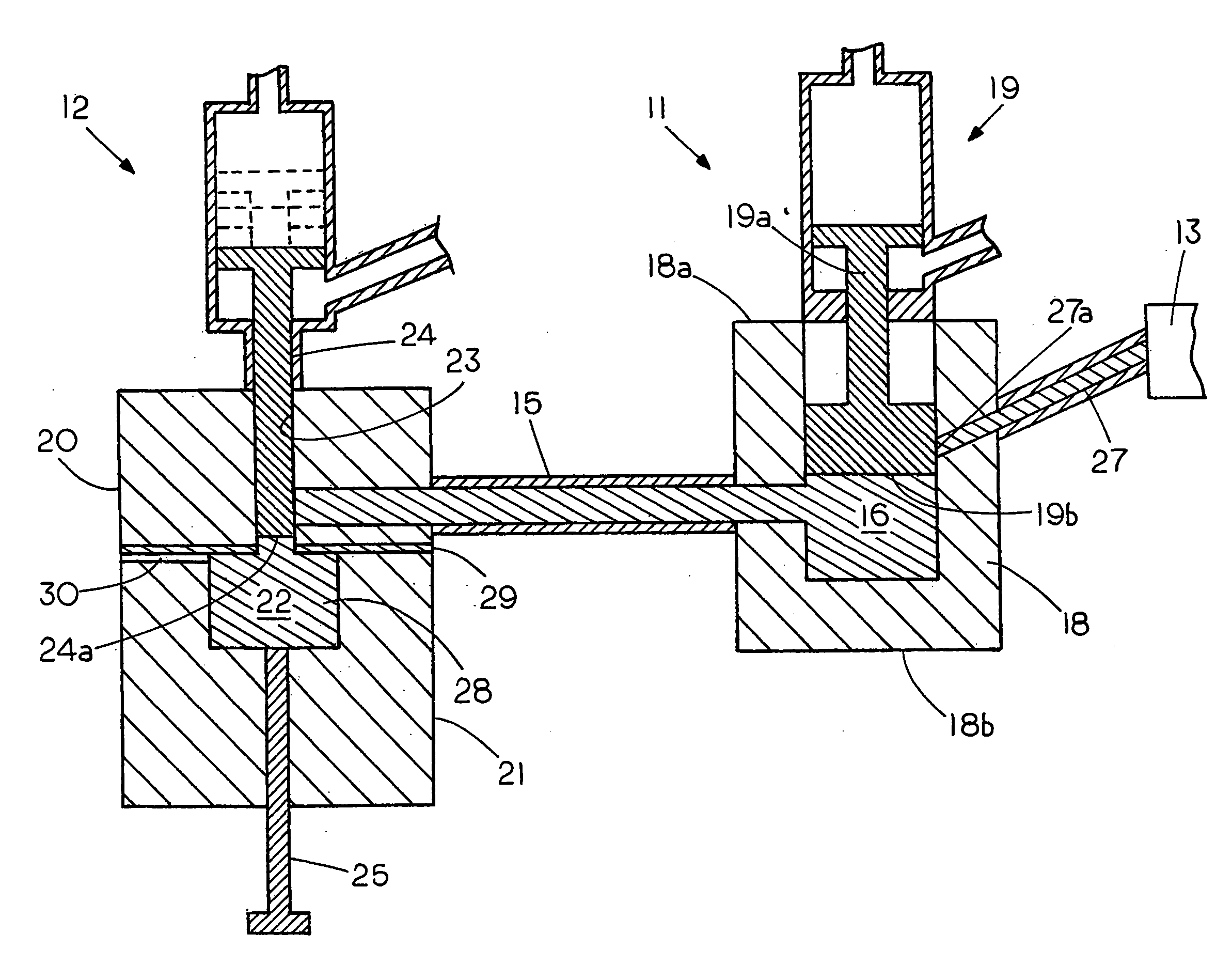

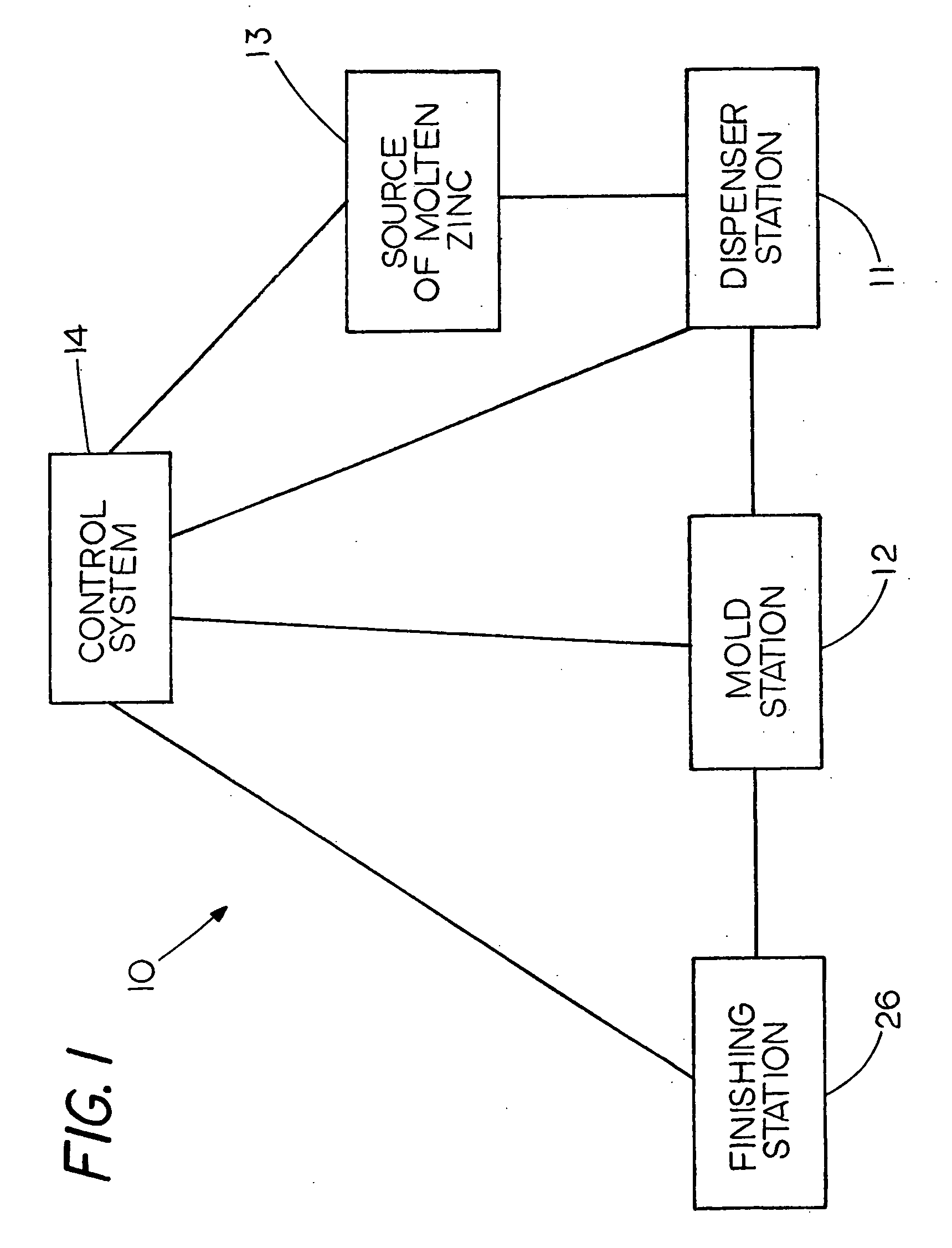

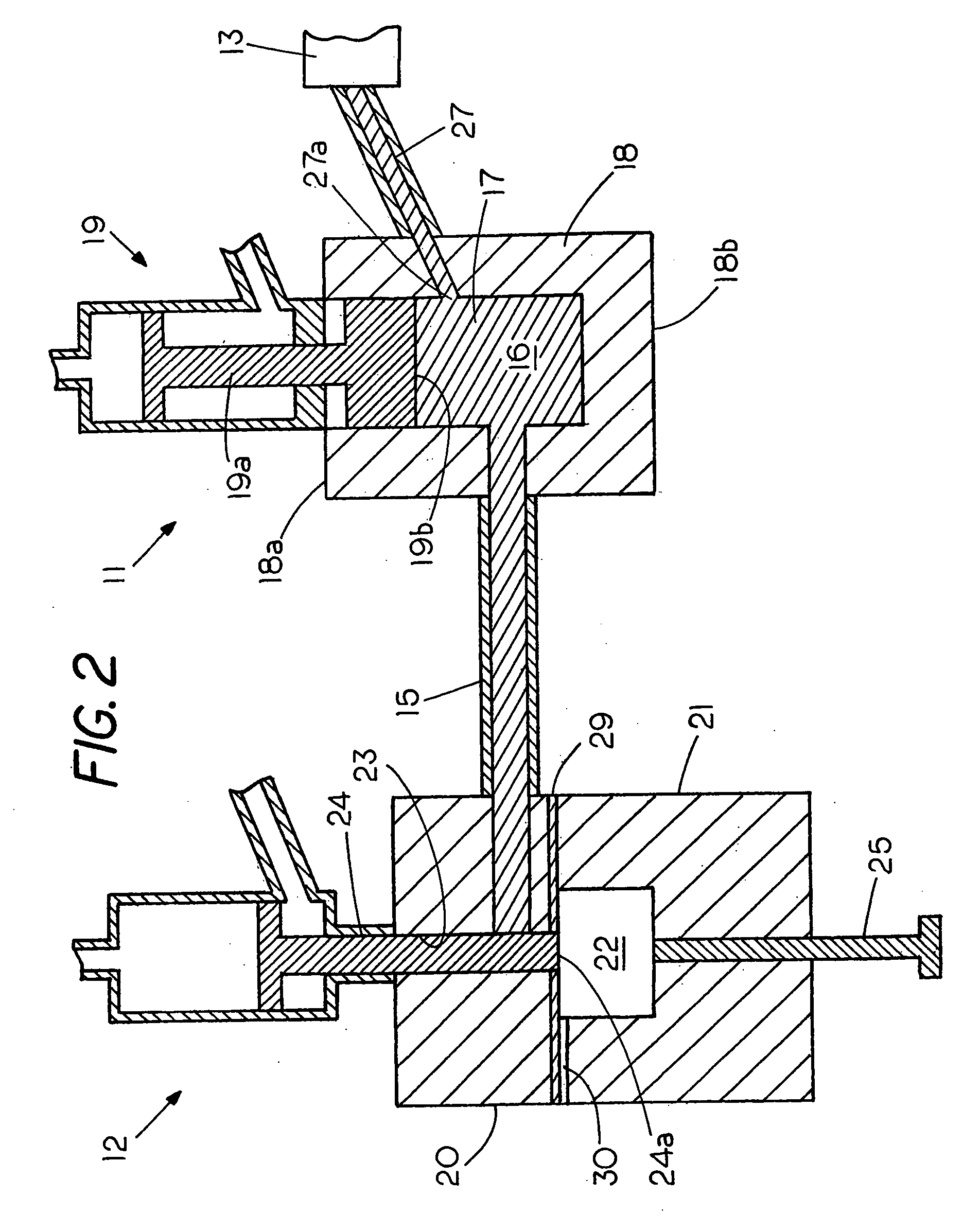

[0015]FIG. 1 shows a schematic diagram of an embodiment of a system 10 for die-casting products free or substantially free of surface blemishes or imperfections. System 10 generally comprises a dispenser station 11 connected to both a mold station 12 and a source of molten zinc 13 with the dispenser station 11, mold station 12 and source of molten zinc 13 linked to a control system 14 that controls the operations thereof. Mold station 12 is also shown connected to a finishing station 26 that is also linked to control system 14, which also controls the operations of the finishing station 26. Finishing station 26 applies a finishing surface treatment to the solidified die-cast products, for example by electroplating, painting or the like. The control system 14 may comprise a variety of devices, such as a computer or a microprocessor-based device, that is capable of monitoring and sending out operational commands to the dispenser station 11, the mold station 12, the source of molten zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com