Feeding device for liquid materials

a technology of liquid materials and feeding devices, which is applied in the direction of positive displacement liquid engines, piston pumps, separation processes, etc., can solve the problems of high manufacturing cost, unfavorable field workers, and complicated structure of conventional mechanical or pneumatic pumps, and achieves cheap manufacturing cost and simplified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

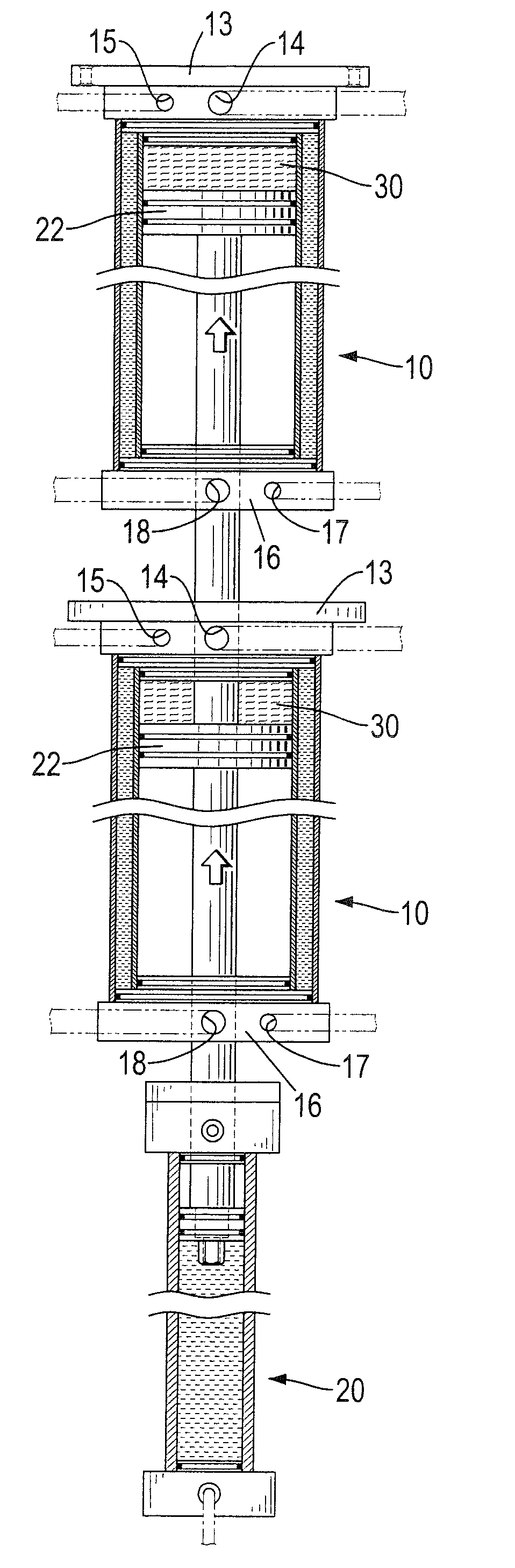

[0016]With reference to FIGS. 1, 2, 3 and 4, a feeding device for liquid materials in accordance with the present invention comprises a storage tank (10) and a hydraulic cylinder (20).

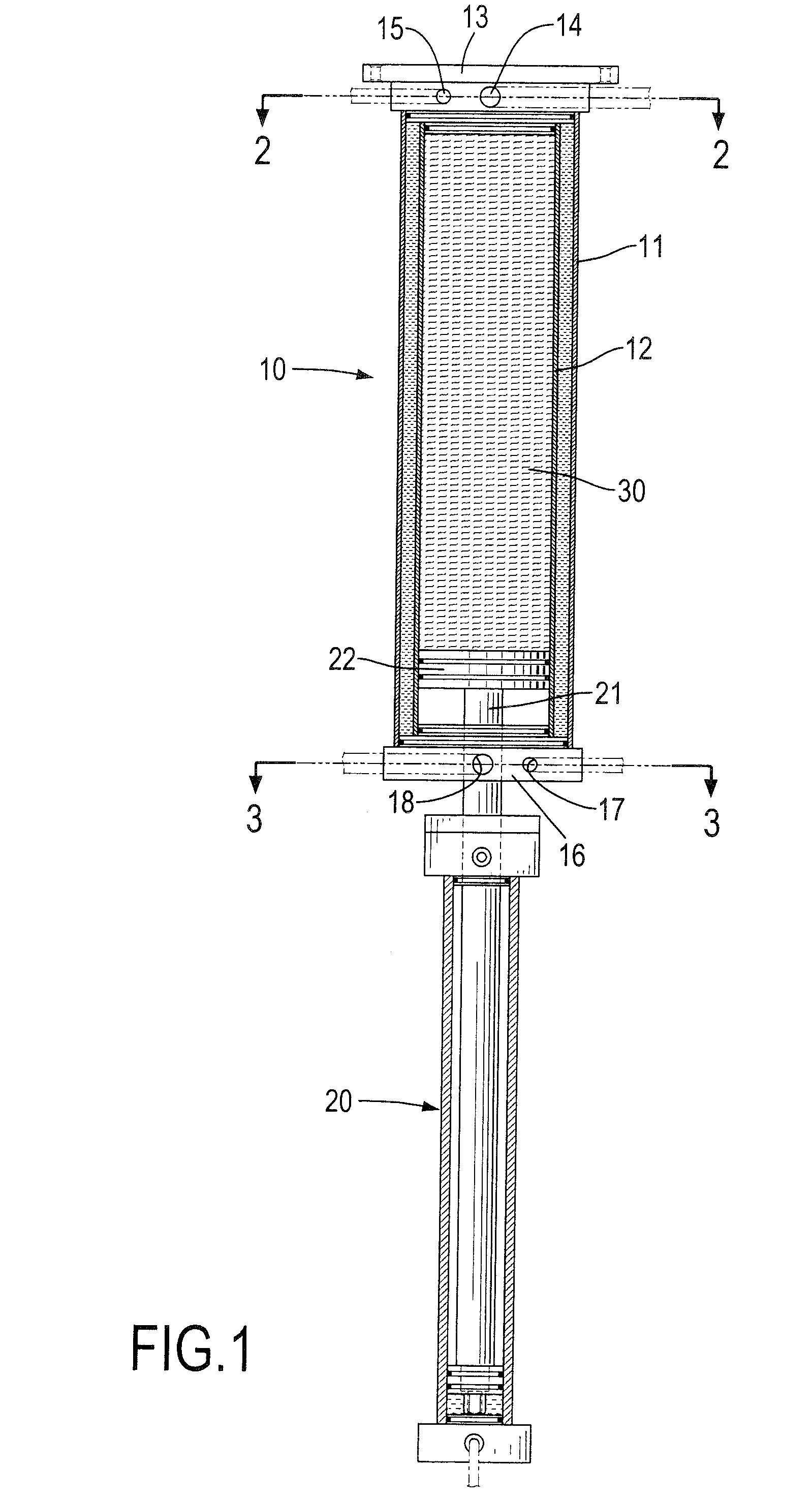

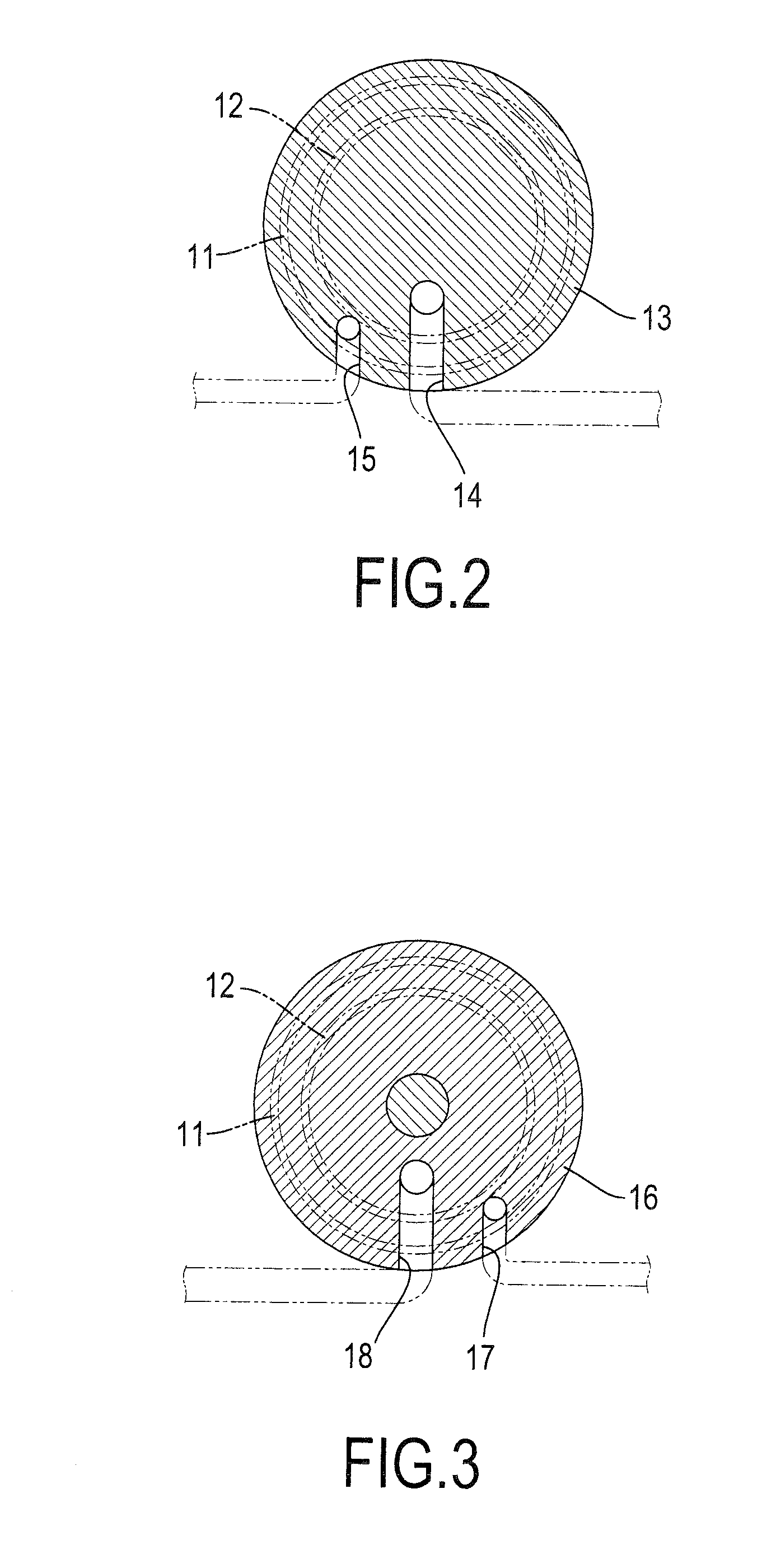

[0017]The storage tank (10) comprises an outer tube (11), an inner tube (12), a receiving space, a front cap (13) and a rear cap (16). The outer tube (11) is thermal conductive and has a front end and a rear end. The inner tube (12) is thermal conductive, is mounted coaxially in and spaced from the outer tube (11) and has a front end and a rear end. The receiving space is defined between the inner and outer tubes (11, 12).

[0018]The front cap (13) is mounted on the front ends of the inner and outer tubes (11, 12) and has a feeding inlet (14) and a front outlet (15). The feeding inlet (14) is defined in the front cap (13), communicates with the inner tube (12) and may be connected to a divider connected to a liquid material supply and a liquid material output through pipelines. The front outlet (15) is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosities | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thermal conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com