Turbomachine with unducted propellers

a turbomachine and propeller technology, applied in the direction of machines/engines, air-flow influencers, transportation and packaging, etc., can solve the problems of reducing the thrust produced by the downstream propeller, the noise generated by the turbomachine when operating, and the turbomachine must comply with relatively severe acoustical certification standards. , to achieve the effect of simple, effective and economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

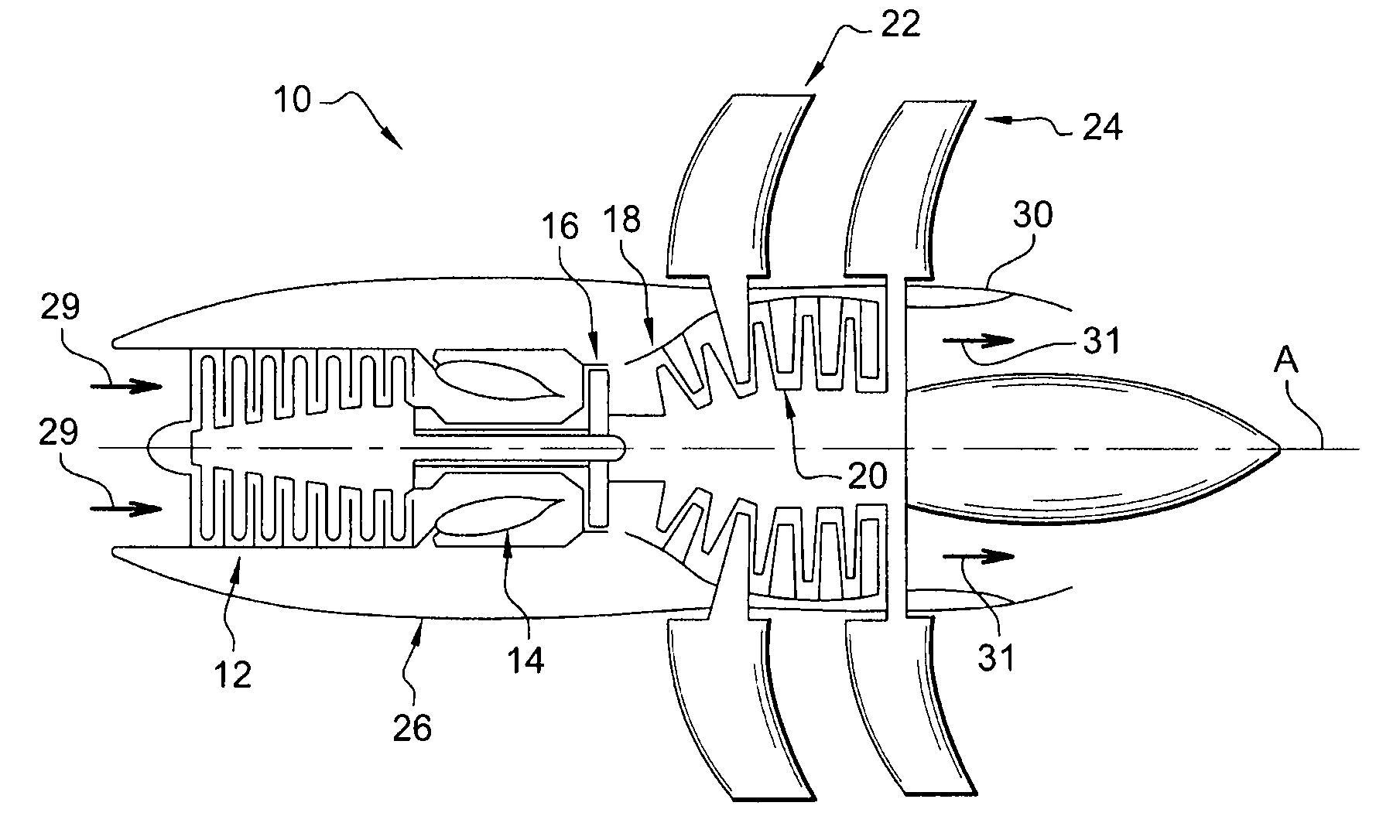

[0025]Reference is first made to FIG. 1 which shows a turbomachine 10 with unducted propellers which comprises from upstream to downstream, in the flow direction of gases inside the turbomachine, a compressor 12, an annular combustion chamber 14, a high-pressure upstream turbine 16, and two low-pressure downstream turbines 18, 20 which are contra-rotating, i.e. they rotate in opposite directions around the longitudinal axis A of the turbomachine.

[0026]Each one of these downstream turbines 18, 20 is secured in rotation to an external propeller 22, 24 which extends radially to the exterior of the nacelle 26 of the turbomachine, with this nacelle 26 being substantially cylindrical and extending along the axis A around the compressor 12, the combustion chamber14, and the turbines 16, 18 and 20.

[0027]The flow of air 29 that penetrates into the compressor 12 is compressed and is then mixed with fuel and burned in the combustion chamber 14, the combustion gases being then injected into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com