Method and apparatus for adjusting variable valve lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

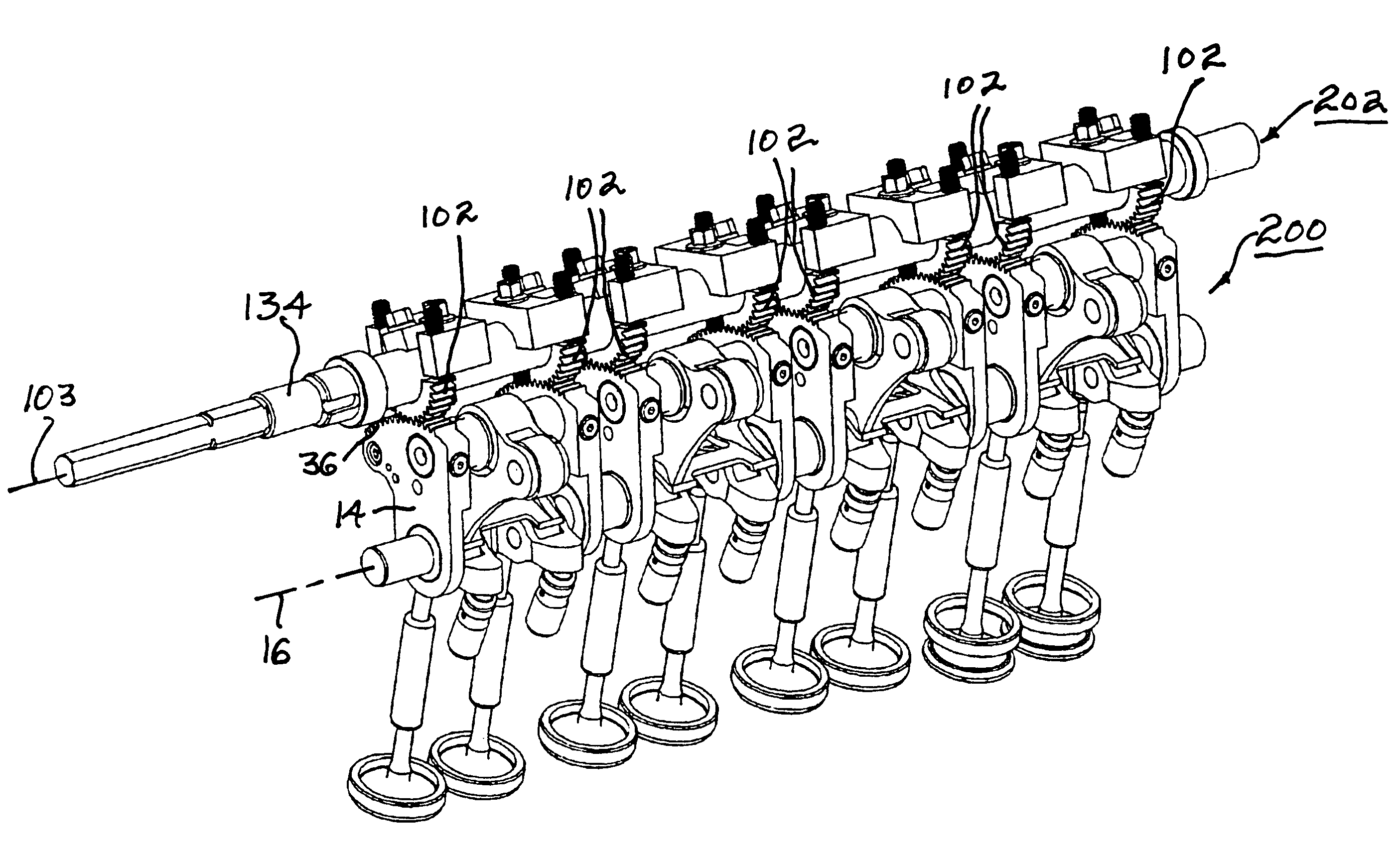

[0015]The present invention provides a method and apparatus for adjusting cylinder-to-cylinder air flow of a CVVL system during engine assembly and calibration to produce smooth idle quality by compensating for normal build tolerances.

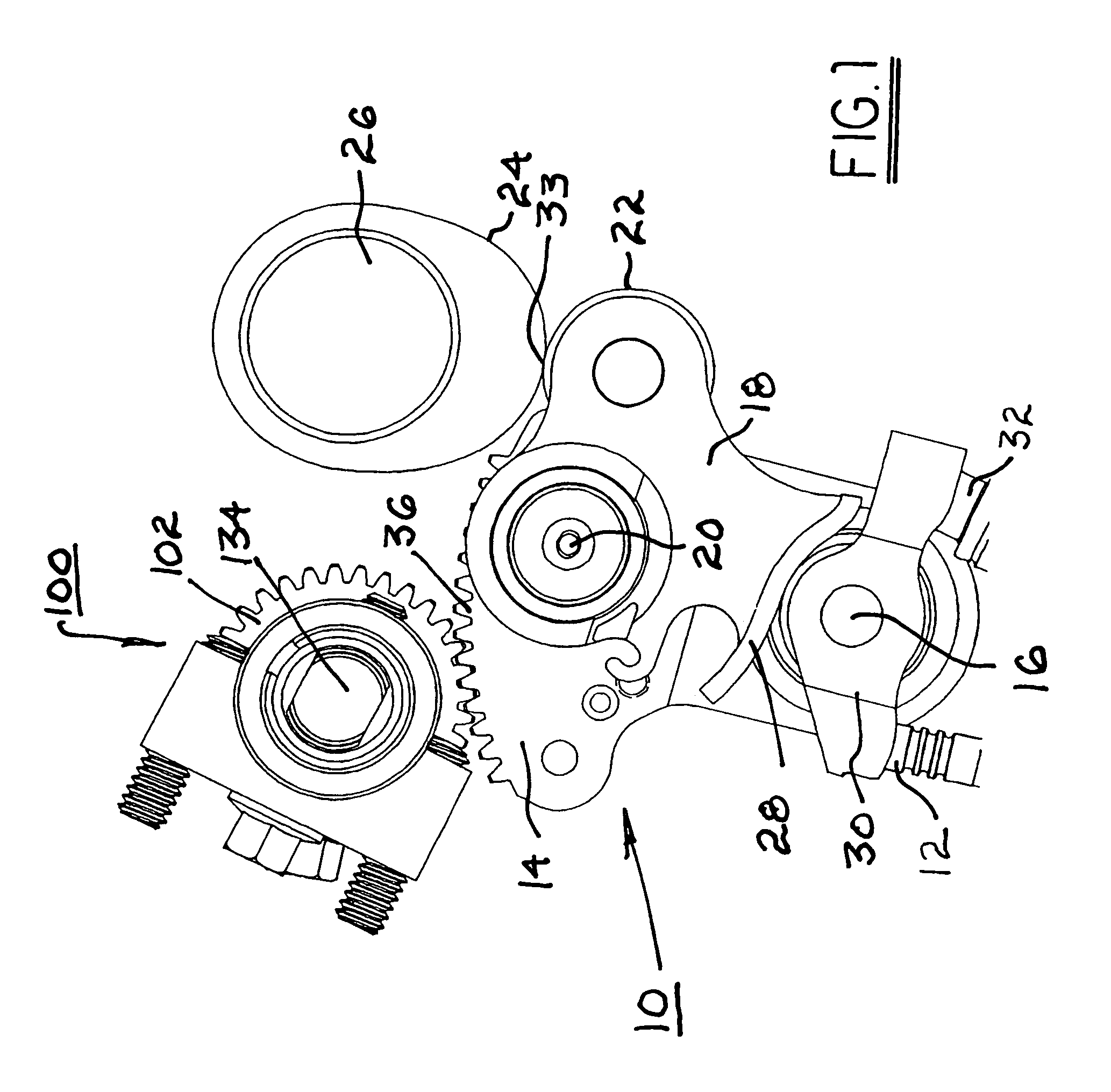

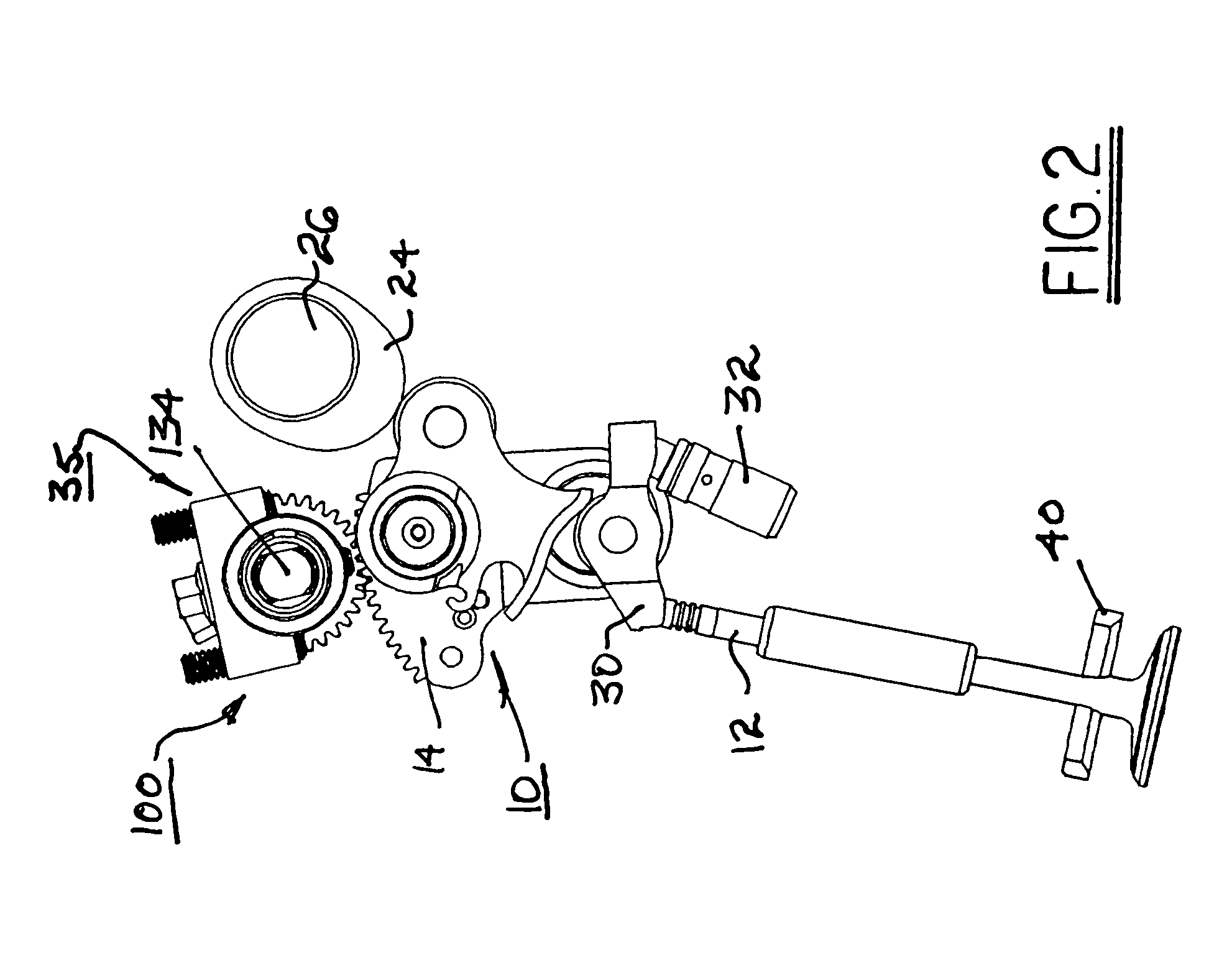

[0016]Referring to FIG. 1, a prior art CVVL mechanism 10 for an individual valve 12 is equipped with an adjustable drive gear assembly 100 in accordance with the present invention, as described in detail below.

[0017]Prior art CVVL mechanism 10 comprises a control arm 14 pivotably mounted on a control arm shaft 16; a cam follower 18 rotatably mounted on a follower shaft 20 on control arm 14, and having a roller 22 for following the surface of a cam lobe 24 disposed on a camshaft 26, and having a contoured shoe 28 for actuating a roller rocker 30 pivotable on a hydraulic lash adjuster 32 to open and close valve 12. The curved shoe 28 has a cam profile which has an extended base circle portion and a sloped portion up to full valve lift. An actuator shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com