Method of positioning containers in a container processing installation, a corresponding positioning device, and an installation including such devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

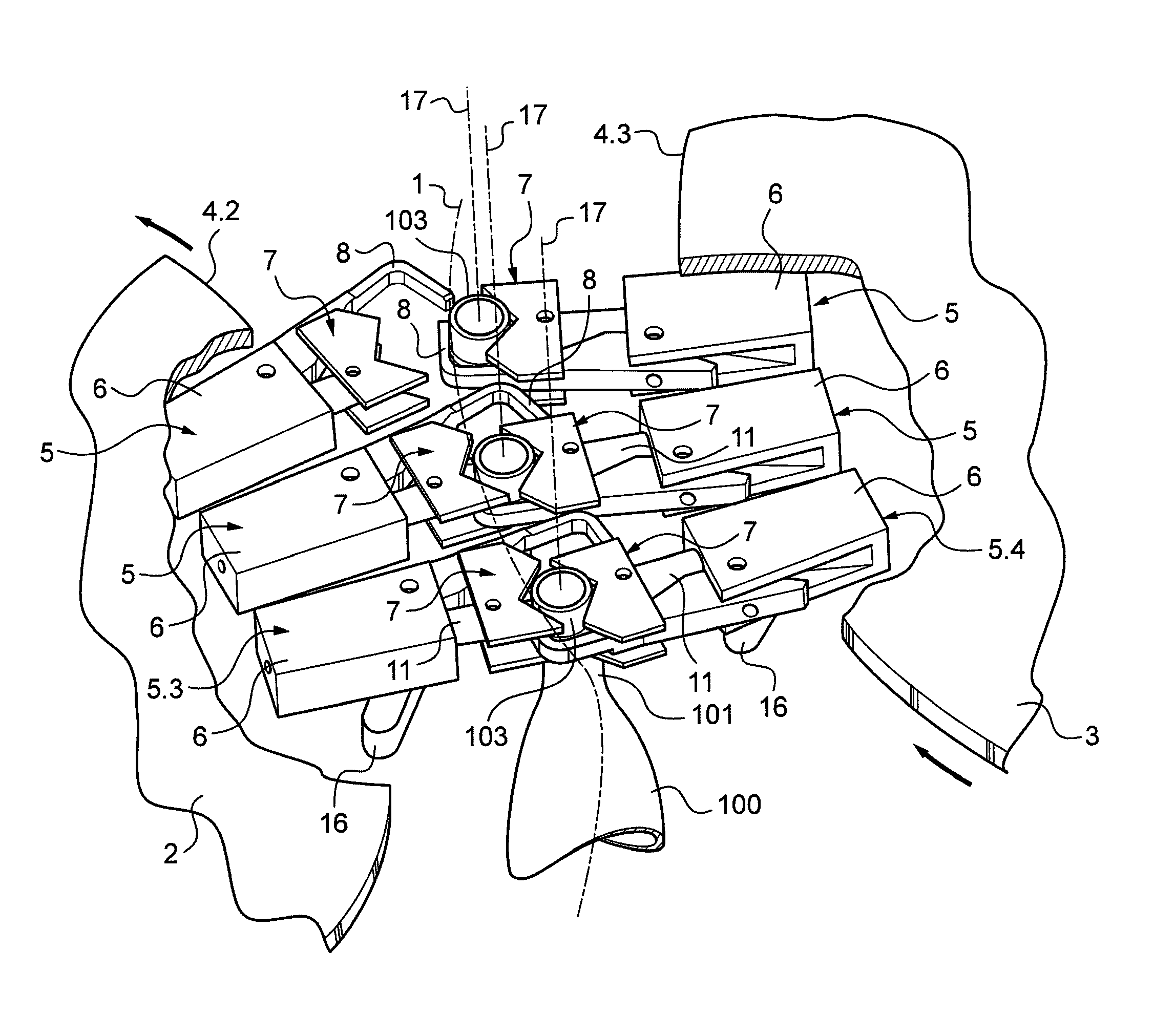

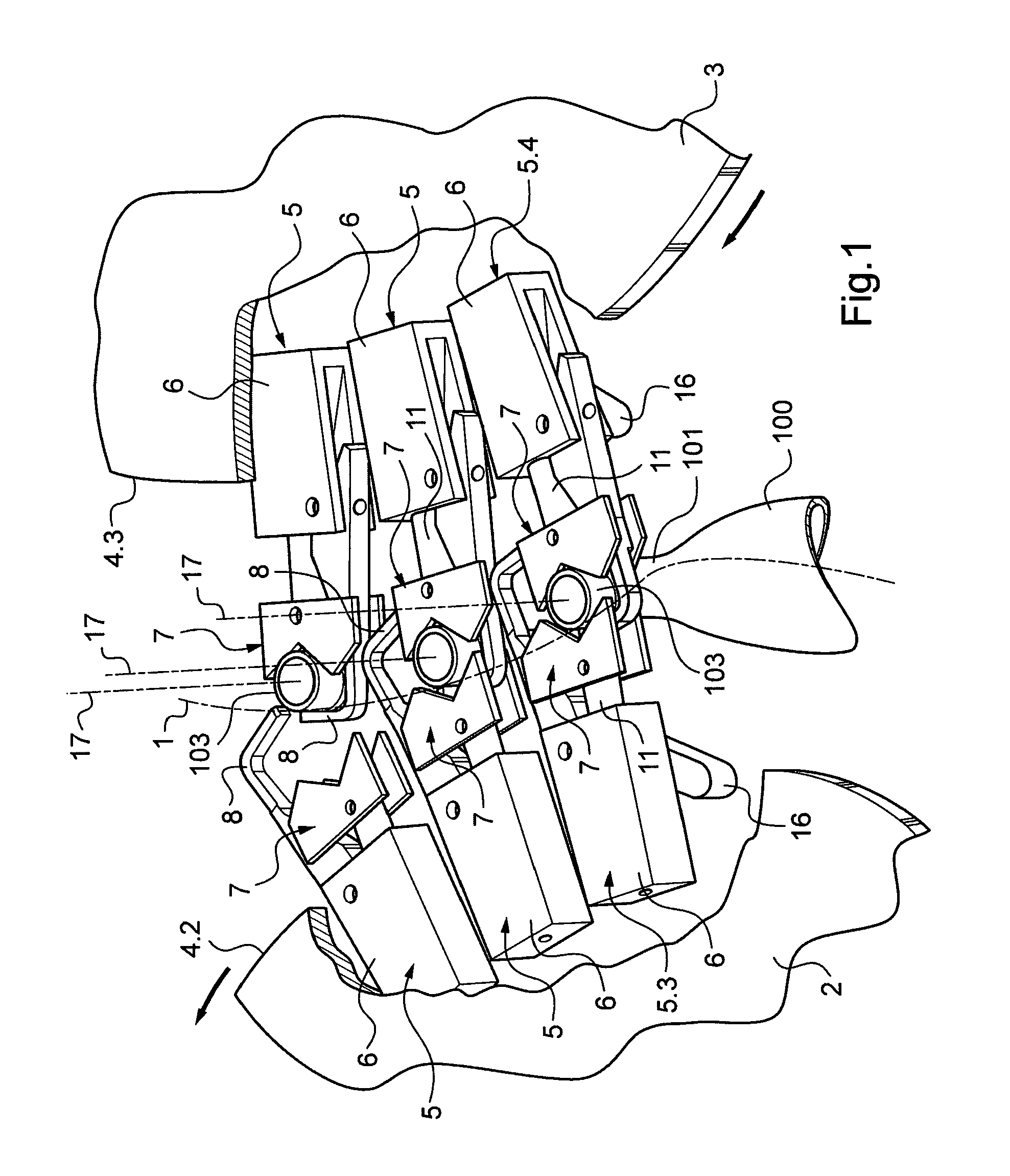

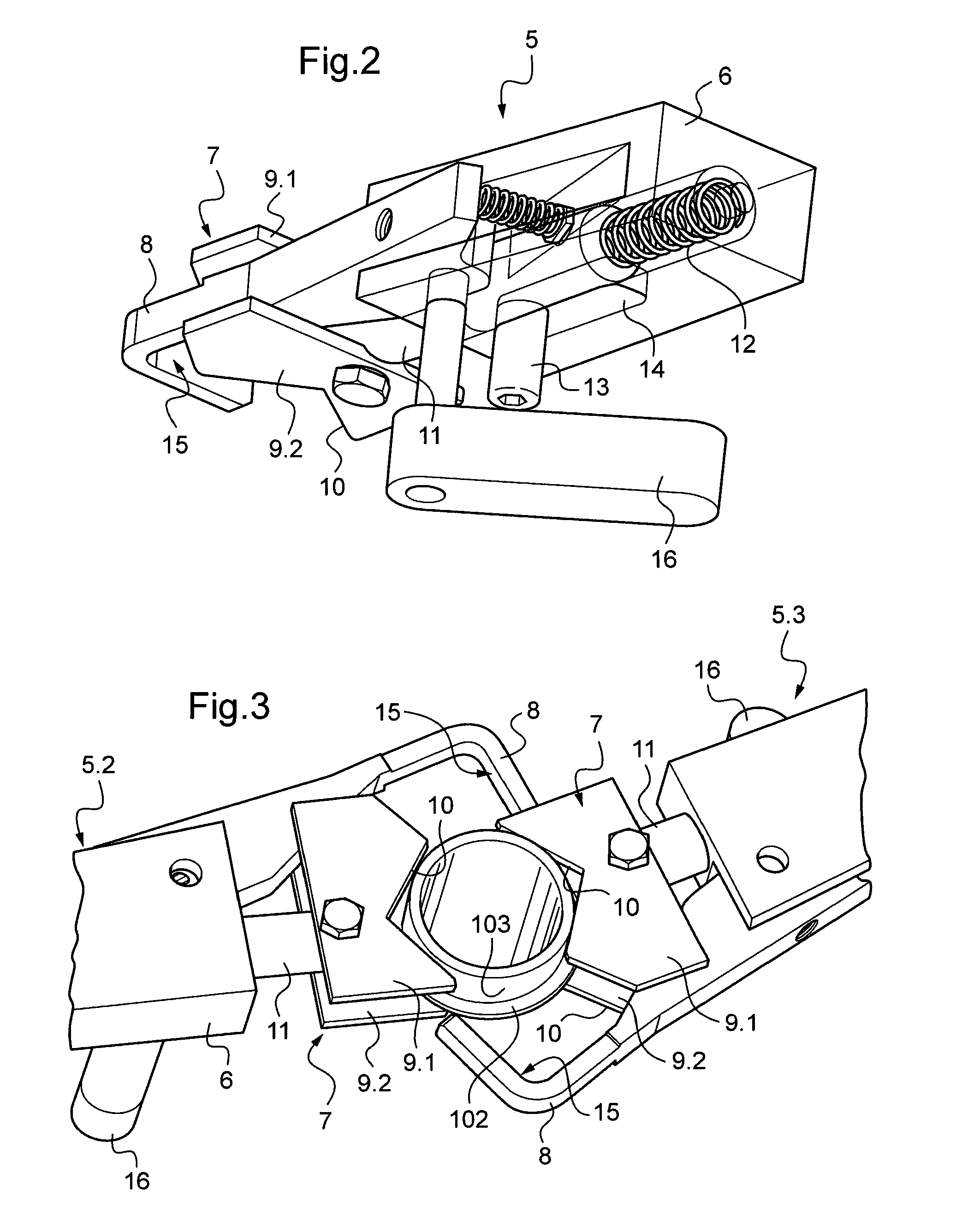

[0045]In the first embodiment, shown in FIGS. 1 to 10, the positioning device 5 comprises a body 6 mounted under the corresponding platform 2, 3, a jaw 7 mounted to slide on the body 6, and a finger 8 mounted to pivot on the body 6.

[0046]The jaw 7 comprises a top plate 9.1 and a bottom plate 9.2 that extend parallel to and facing each other while being spaced apart from each other. The spacing between the plates 9.1 and 9.2 is such that:[0047]the collar can be inserted in part between the plates 9.1, 9.2 and can rest on the bottom plate 9.2;[0048]the bottom plate 9.2 can bear laterally against the portion of the neck that is situated immediately under the collar 102;[0049]the top plate 9.1 can bear laterally against a portion of the mouth segment 103 that is situated above the collar 102.

[0050]Each plate 9.1, 9.2 has an edge in which a cutout 10 is provided for receiving the neck 101 of a container (the faces of the cutouts 10 form bearing faces via which the jaw bears against the n...

second embodiment

[0073]In the second embodiment, shown in FIG. 11 (the upstream platform 2 is situated on the right), the device comprises, as above, a body 6 slidably receiving a jaw 7 so that said jaw can slide between a maximum deployed position, back into which it is resiliently urged, and a minimum deployed position. The structure of the jaw 7 merely comprises a single bottom plate, but it can be identical to the above-described jaw.

[0074]The abutment corresponding to each platform is formed by a guide rail 25.2, 25.3 that is fastened to the structure of the installation on the movement line slightly above the jaw 7. The guide rail 25.2, 25.3 surrounds the platform 2, 3 in question between the feed zone for feeding in containers and the removal zone for removing the containers, so that the jaws 7 push the mouth segments against a face of the guide rail 25.2, 25.3 (forming a reference face) under the action of the return springs that urge the jaws back to their maximum deployed positions.

[0075]T...

third embodiment

[0088]The reference face can also be formed by the bearing surface of the jaw, in particular in the

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com