Golf ball with very low compression and high cor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

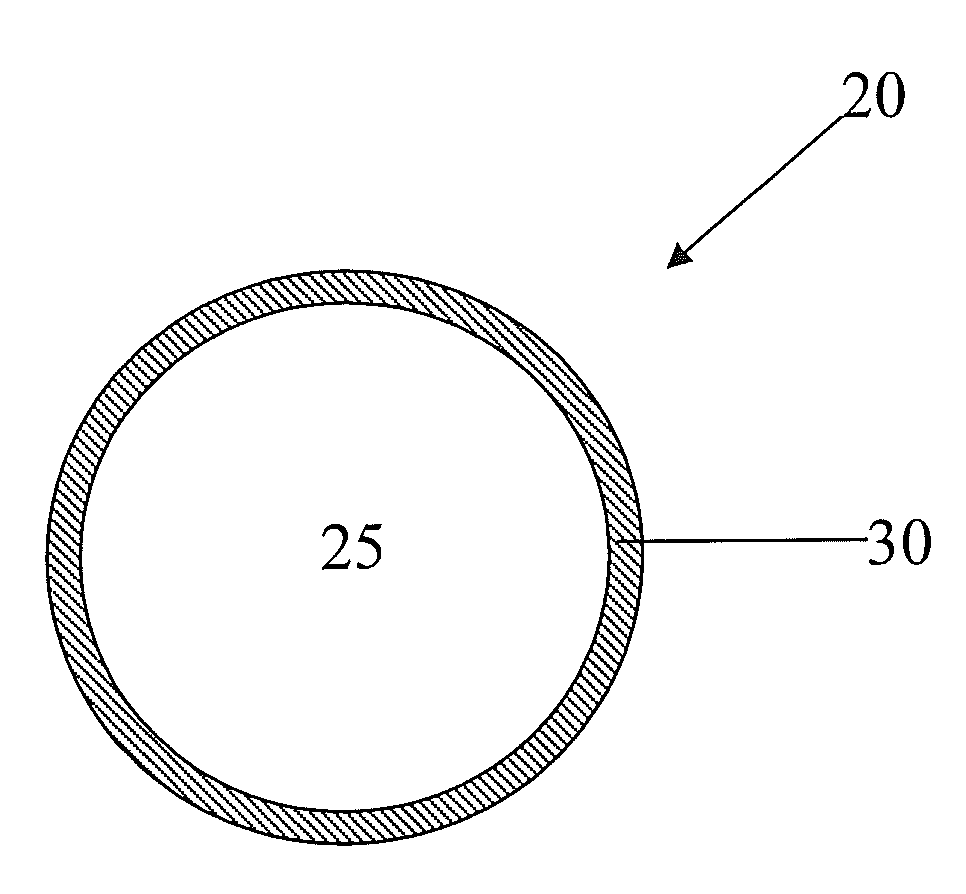

[0024]As shown in FIG. 1, a golf ball 20 includes a core 25 and a cover 30. The core 25 is a solid core and cover 30 is disposed on the core 25. Preferably, the core 25 is compression molded into a spherical shape and the cover 30 is injection molded over the core 25.

[0025]The golf ball 20 preferably has a diameter of at least 1.68 inches and a mass of approximately 45 grams. The golf ball 20 preferably has a coefficient of restitution (“COR”) of at least 0.780, more preferably at least 0.790, and most preferably at least 0.8. The golf ball 20 preferably has an aerodynamic surface pattern such as disclosed in U.S. Pat. No. 7,566,281, which is hereby incorporated by reference.

[0026]The core 25 is preferably composed of a polybutadiene-based mixture generally comprising a single neodymium-catalyzed polybutadiene, zinc oxide, zinc stearate, peroxide and zinc pentachlorothiophenol. The polybutadiene is preferably present in an amount ranging from 55 to 75 weight percent of the core, mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com