Hydragen-oxygen electrolyzing device and carbon paper electrodes thereof with material-changed outer surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

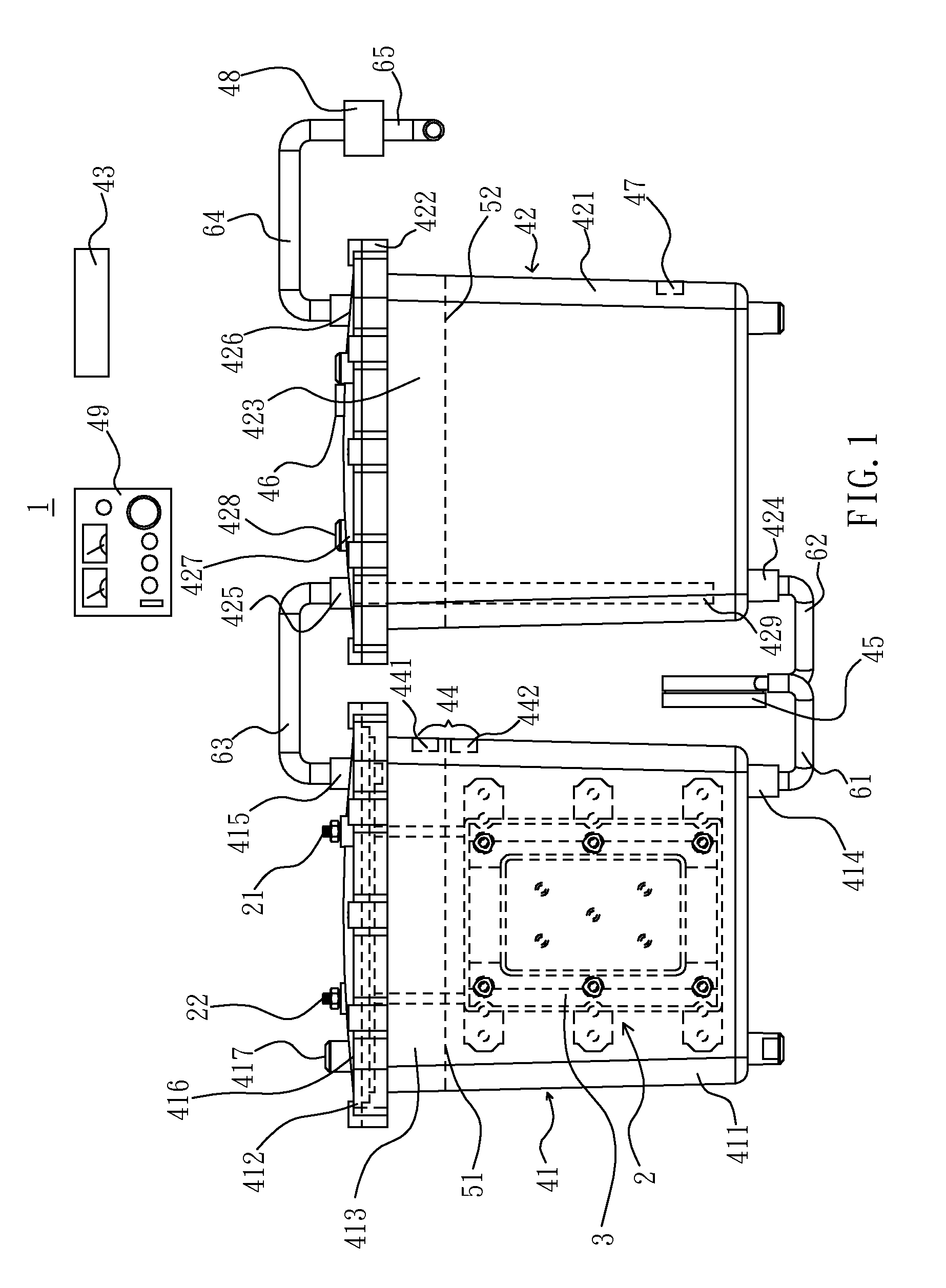

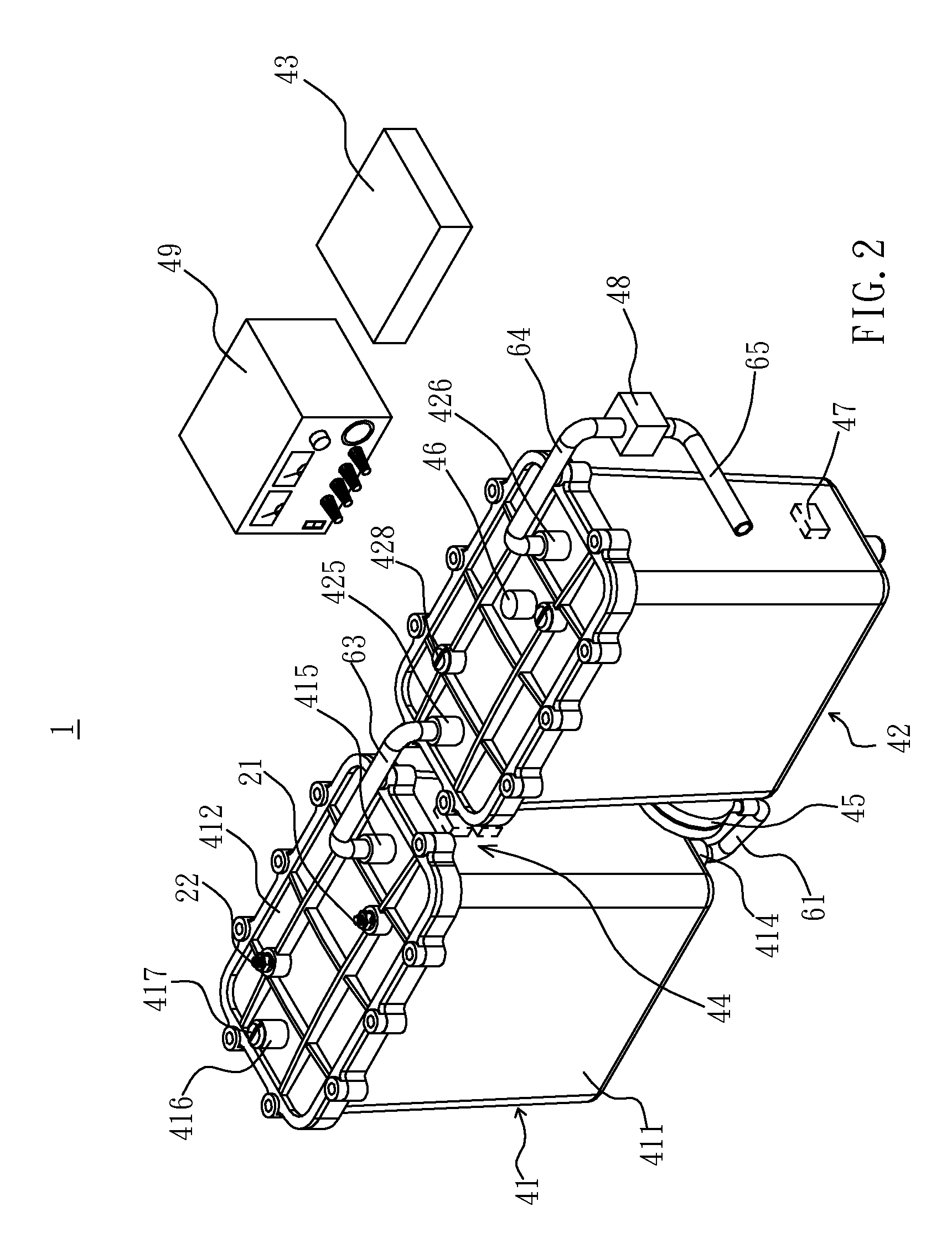

[0037]Referring to FIGS. 1 and 2, the hydrogen-oxygen electrolyzing device 1 of the first embodiment according to the present invention includes an electrolyzing structure 2, a first container 41, a second container 42, a controller 43, a level sensor 44, a pump 45, a gas pressure sensor 46, a second level sensor 47, an anti back fire valve 48 and a DC power supply 49. The electrical connections are prior art and the pump 45 can be a membrane pump.

[0038]Referring to FIG. 3, the first embodiment of the electrolyzing structure 2 includes a serial cell 3, a first conductor 21 and a second conductor 22. The serial cell 3 further includes a plurality of electrodes 20, a first frame 31, a second frame 32, a plurality of metal sheets 33, a plurality of insulating sheets 34, a plurality of insulating rods 35, a plurality of insulating pads 36, a plurality of insulating bolts 37 and a plurality of insulating nuts 38.

[0039]Referring to FIG. 4, each of the electrodes 20 is a carbon paper elect...

third embodiment

[0055]Referring to FIG. 7, a electrolyzing structure 7 in the third embodiment according to the present invention includes a plurality of serial cells 71, 72, 73, a first conductor 74, a second conductor 75 and a plurality of “U”-shaped third conductors 76. The serial cells 71, 72, 73 provide a structure of serial elongation in which the two serial cells 71, 72 are disposed at the two outermost sides of the electrolyzing structure 7. The structures of the serial cells 71, 72, 73 are the same as the electrode serial cell 3 shown in FIG. 3. The serial cells 71, 72, 73 each have a first frame 711, 721, 731 and a second frame 712, 722, 732 respectively; the first frames 711, 721, 731 have a first groove 713, 723, 733 respectively; the second frames 712, 722, 732 have a second groove 714, 724, 734 respectively; The serial cell 73 is disposed between the two serial cells 71, 72; the first frame 731 and the second frame 732 press against the second frame 712 and the first frame 721.

[0056]T...

fourth embodiment

[0057]Referring to FIG. 8, an electrolyzing structure provided in the fourth embodiment according to the present invention includes a plurality of serial cells 81, 82, 83, a first conductor 84 and a second conductor 85. The serial cells 81, 82, 83 constitute a structure of parallel extension with the two serial cells 81, 82 are disposed at the two outermost sides laterally.

[0058]The serial cells 81, 82, 83 each have a first frame 811, 821, 831 and a second frame 812, 822, 832, respectively; a plurality of metal sheets 813 and a plurality of insulation sheets 824 are disposed between the two lateral sides of both the first frame 811 and the second frame 812 respectively. The groove 815 of the first frame 811 is joined to the first conductor 84; the groove 825 of the second frame 822 is joined to the second conductor 85.

[0059]The structural arrangement for the serial cells 81, 82, 83 is the same as the serial cell 3 shown in FIG. 3, but the two first frames 811, 831 contact with the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com