Rear view mirror

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

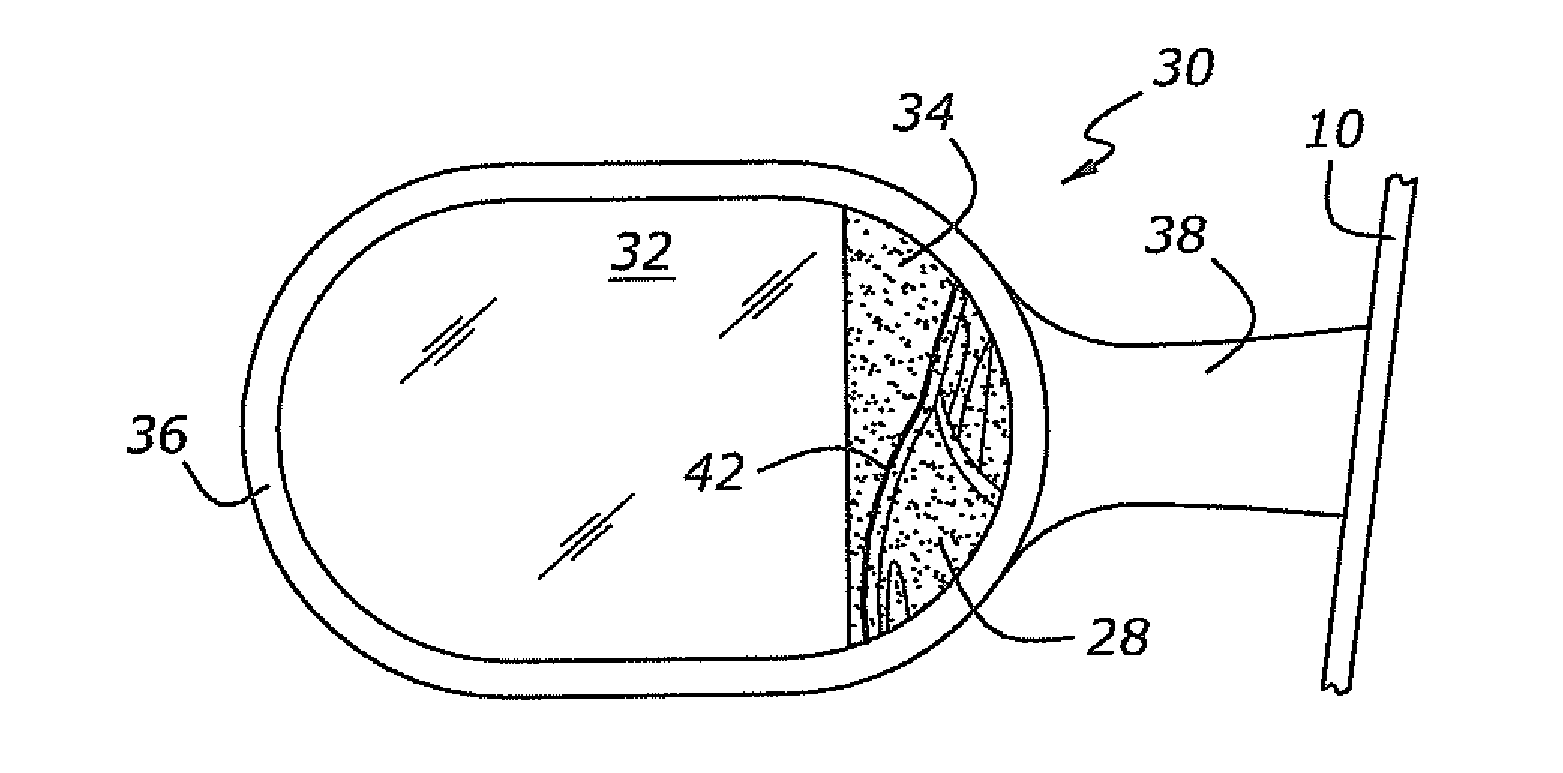

[0029]Referring to FIG. 4, a mirror assembly 30 having a first surface 32 (alternately called a viewing section) and a second surface 34 (alternately called an alignment section) is shown mounted in housing 36. Housing 36 has an arm 38 for attaching the mirror assembly 30 to vehicle 10. In one embodiment, second surface 34 is less reflective than first surface 32. Second surface 34 is etched with a targeting feature, which in one embodiment is a cross-hair 40 to aid in aligning the mirror assembly 30 properly. In particular, a feature on the car, such as a door handle (not shown), is designated to be the target point for cross-hair 40 to ensure suitable alignment of mirror assembly 30.

[0030]Alternatively, in FIG. 5, the targeting feature is a targeting outline 42 for aligning the first surface 32 of mirror assembly 30 is an outline of the outside surface of the vehicle. When, the image of the outside of vehicle 28 aligns with targeting outline 42, the first surface 32 of the mirror...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com