Hydrocyclone

A hydrocyclone and overflow technology, applied in the direction of the cyclone device, the device in which the axial direction of the cyclone can be reversed, etc., can solve the problems of downstream processing influence, accelerated wear of profit equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention relates to design features of this type of hydrocyclone that facilitate the separation of liquid or semi-liquid material mixtures into the desired phases of interest. Hydrocyclones are designed for stable operation with maximized throughput and good physical separation process parameters.

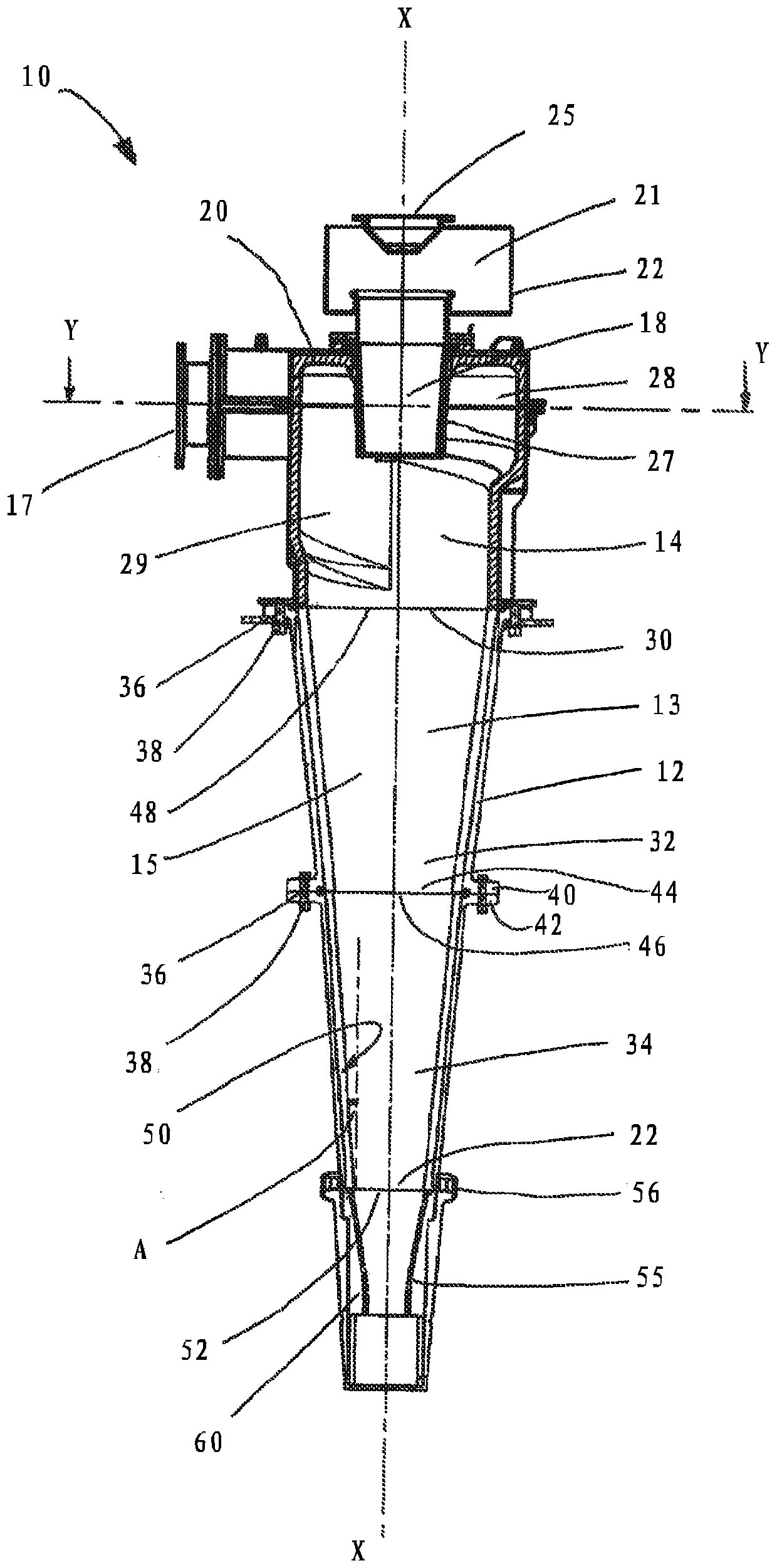

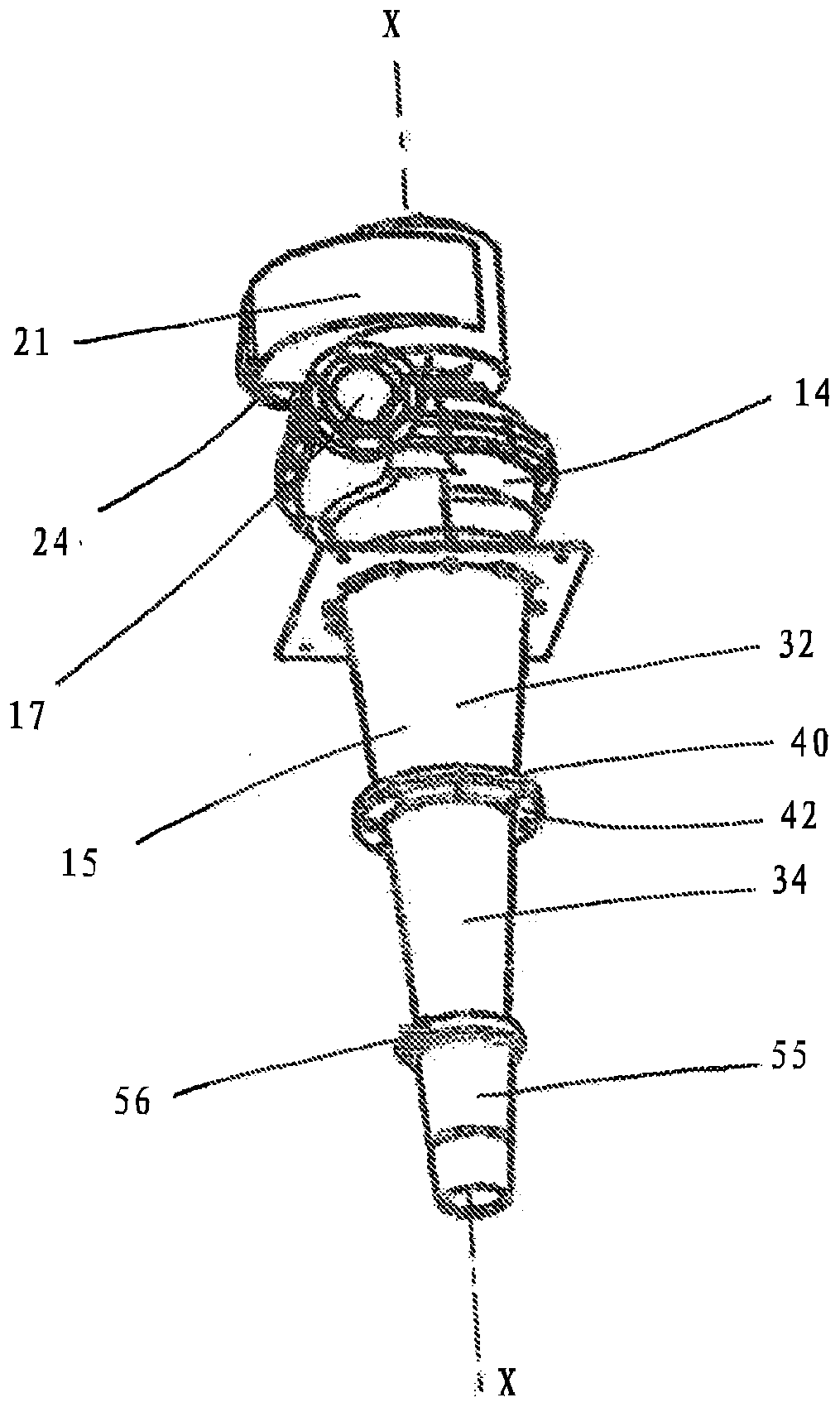

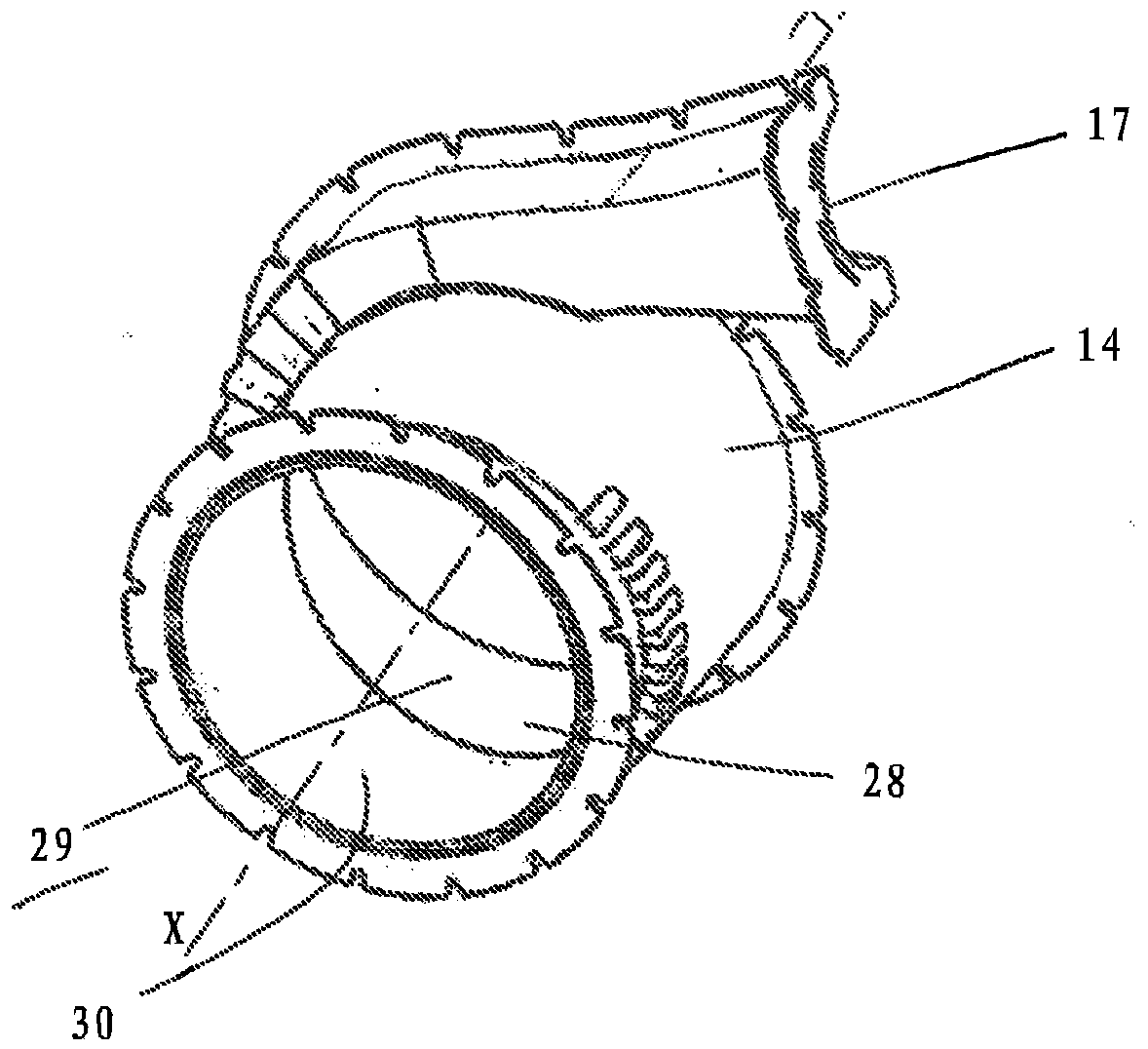

[0030] In use, a hydrocyclone is usually arranged vertically or nearly vertically with its central axis X-X. refer to figure 1 , shows a schematic cross-sectional view of a hydrocyclone 10 comprising a main body 12 having a chamber 13 defined therein. Chamber 13 includes an inlet (or feed) section 14 and a conical separation section 15 . The hydrocyclone also includes a cylindrical feed inlet port 17 of circular cross-section for feeding the particle-containing mixture in the form of a particle slurry into the inlet portion 14 of the chamber 13 .

[0031] Centrally located in the flat, disc-shaped upper (top) wall 20 of the chamber 13 is an overflow outlet (h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com