Manufacture of top plate for an elastomeric rail fastening assembly

a technology of elastomeric rails and fastening assemblies, which is applied in the direction of railway tracks, ballastways, constructions, etc., can solve the problems of unnecessarily increasing the weight and cost of the top plate, unfavorable flashing and positional variations of the socket, and considerable thickness of the metal backing of the frusto-conical surface of the top pla

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

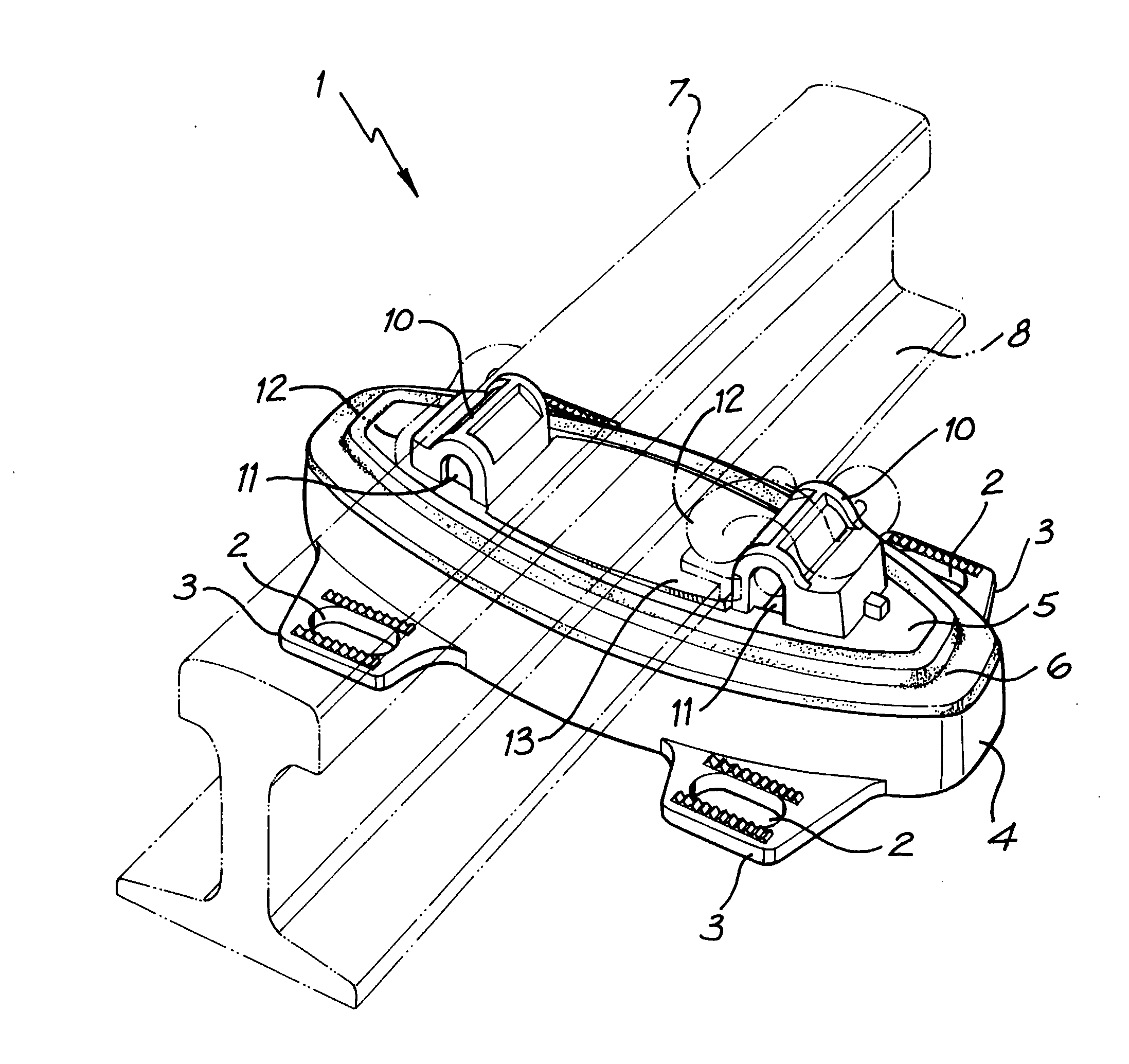

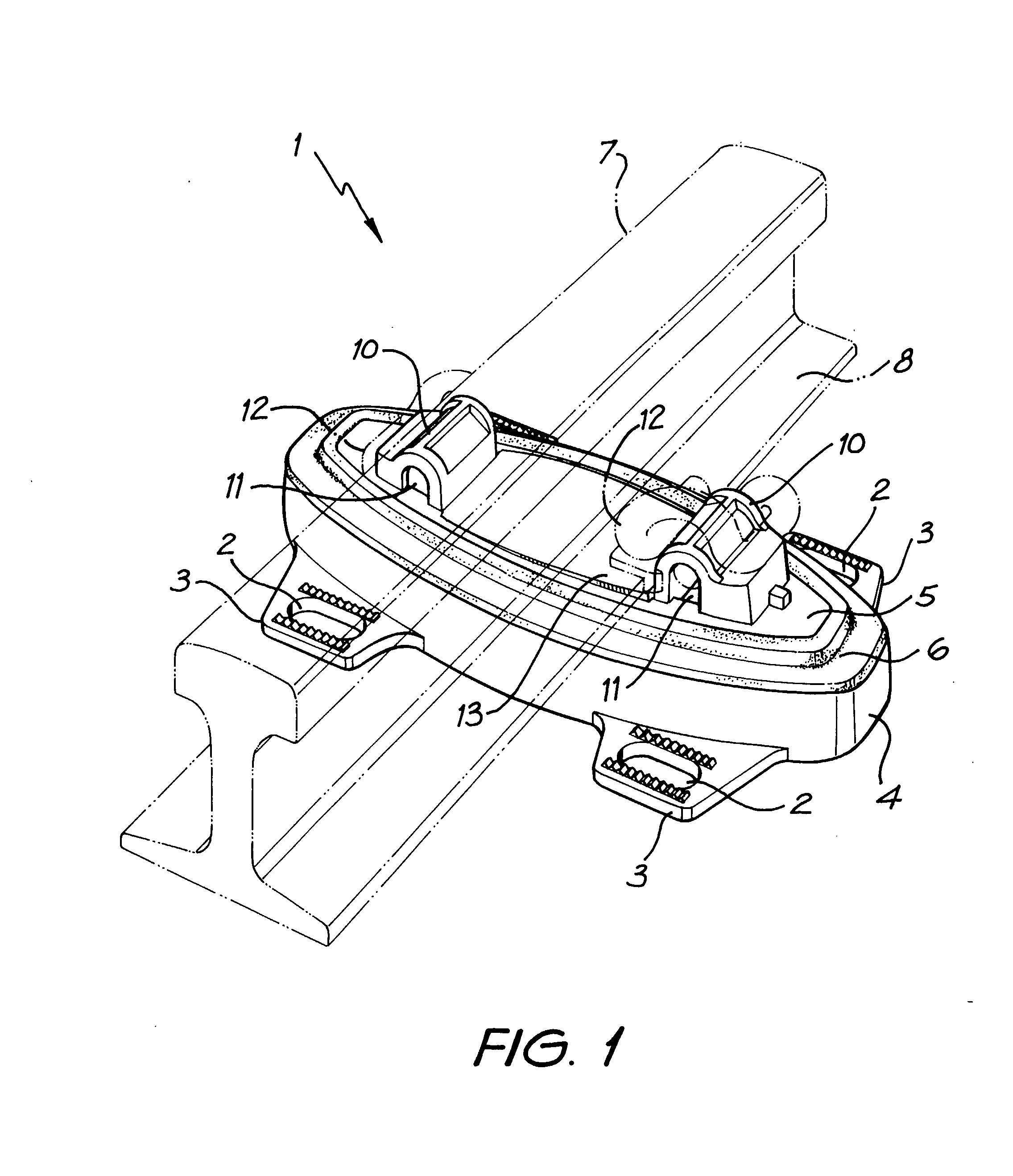

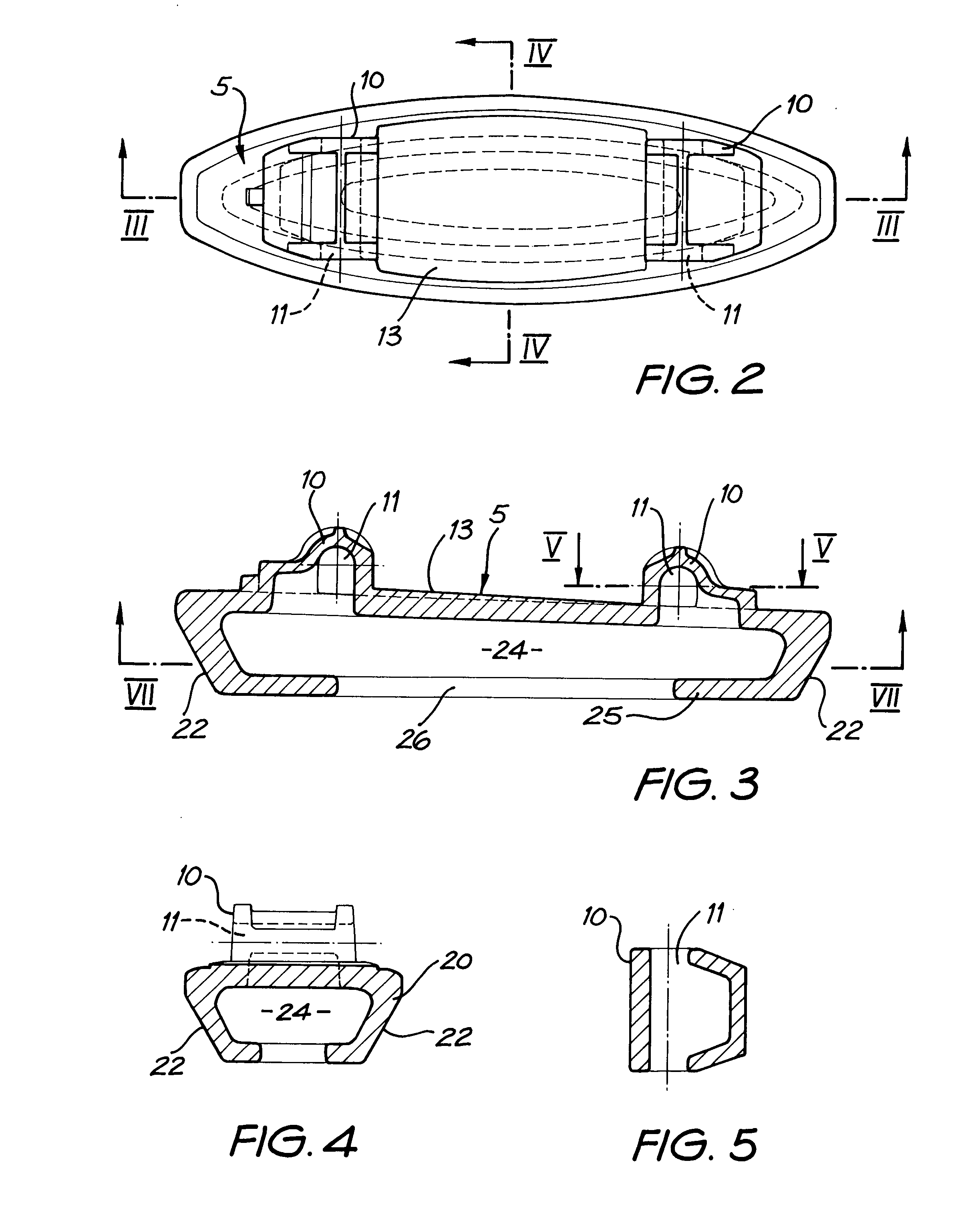

[0021]The assembly 1 shown in FIG. 1 is attached to a track foundation by screw spikes (not shown) driven downwardly through apertures 2 in four anchor lugs 3 arranged in pairs at each side of a bottom plate 4 of the assembly. The plate 4 is made from cast iron. A cast iron top plate 5 is mounted centrally in an opening in the upper surface of the bottom plate 4 and is held in place by a thick layer 6 of an elastomeric material such as rubber, sandwiched between opposed and spaced frusto-conical surfaces provided respectively on the two plates 4 and 5. The frusto-conical surface 5 tapers downwardly. The layer 6 is vulcanised to both plates 4 and 5.

[0022]A track rail 7, shown diagrammatically in broken outline, has a bottom flange 8 that locates between two spaced clip mounts 10 projecting upwards from the top plate 5 and cast integrally with it. Each mount 10 is formed with a horizontal and open-ended socket 11 for the reception of one end-portion of a resilient steel rail holding c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com