Applicator for applying fluid to a substrate, comprising valve mechanisms, method for cleaning said applicator, and valve mechanisms for said applicator

a technology for applying fluids and substrates, which is applied in the direction of cleaning processes, cleaning apparatus, cleaning using liquids, etc., can solve the problems of affecting the cleaning effect, etc., and achieves the effects of reducing the risk of damage, avoiding clogging, and being sensitive to damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

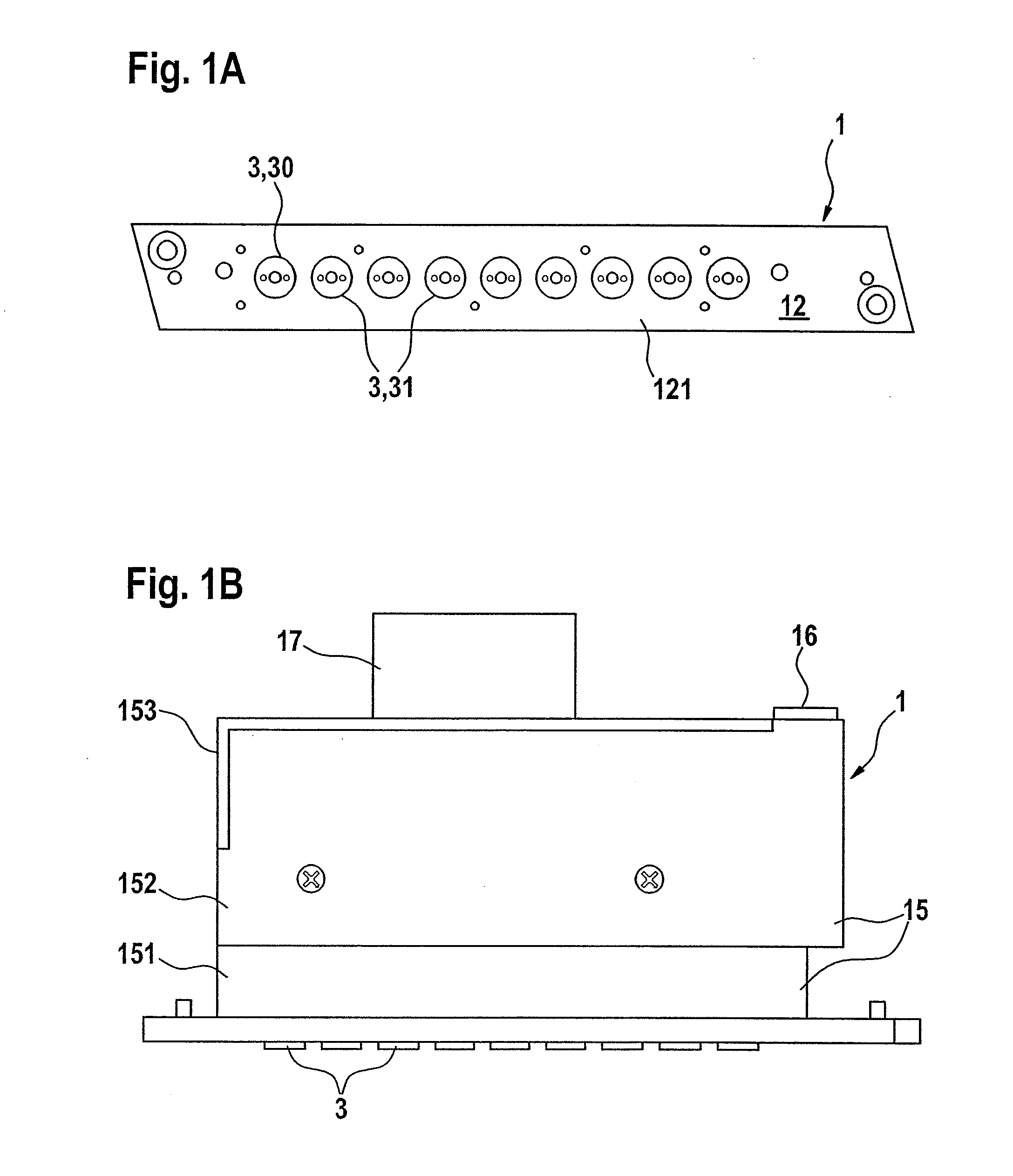

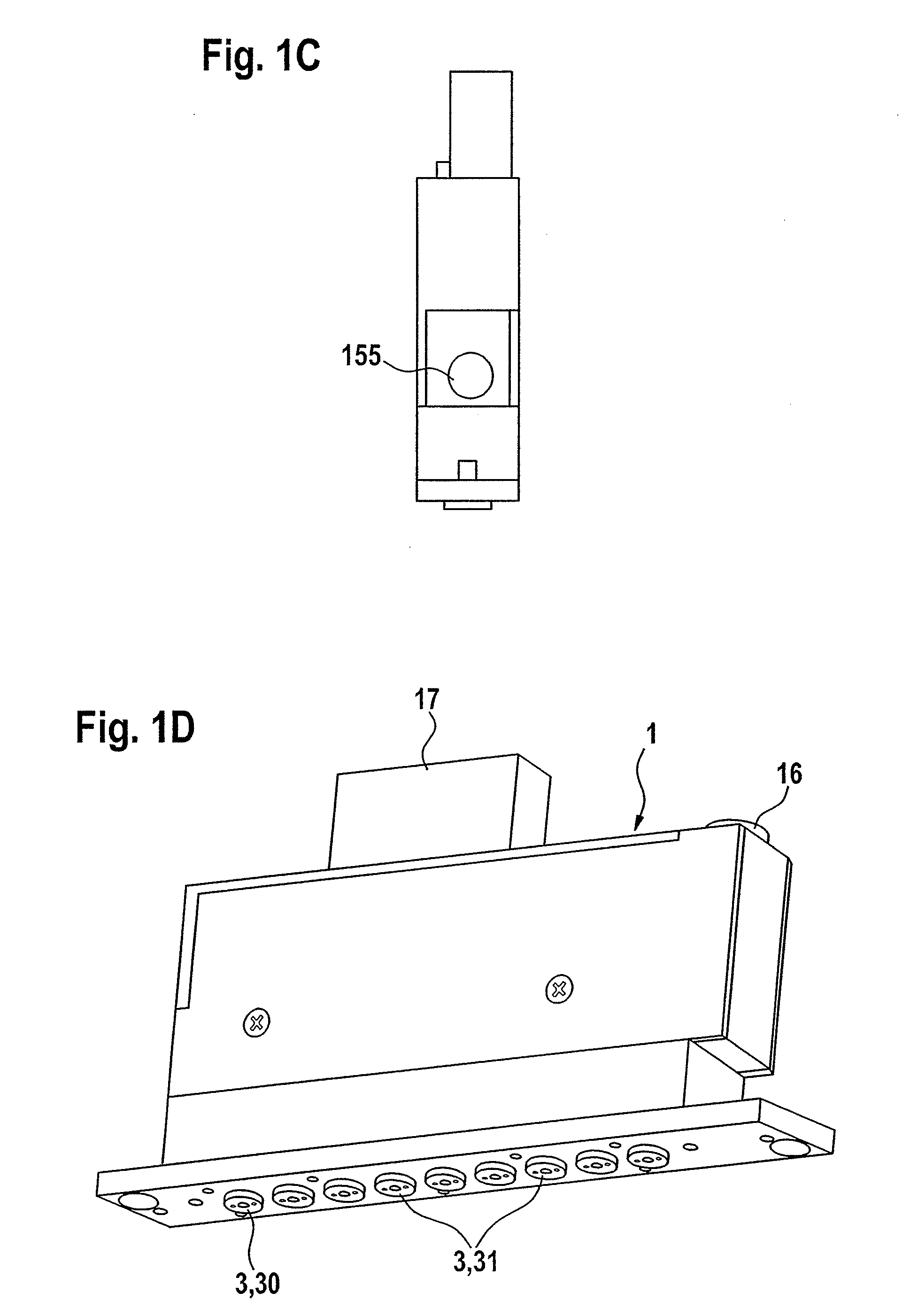

[0026]The application device according to the invention shown in FIGS. 1A to D comprises a box-like valve body 15 which is composed of a lower socket portion 151 and an upper cover portion 152. The lower portion 151 is closed by a narrow elongate nozzle plate 121 which receives valve nozzles 3. The valve nozzles 3 are arranged in a straight row on the nozzle / application side 12. On the opposite side, the application device 1 has an electrical plug-in connection 17 and a connecting opening 16 for application fluid. In the practical example the row of valve nozzles 3 is defined by eight application valve nozzles 31 and one cleaning valve nozzle 30 which closes the row of nozzles. The cleaning valve nozzle 30 is according to the invention arranged at the end of the row of nozzles opposite the connecting opening 16.

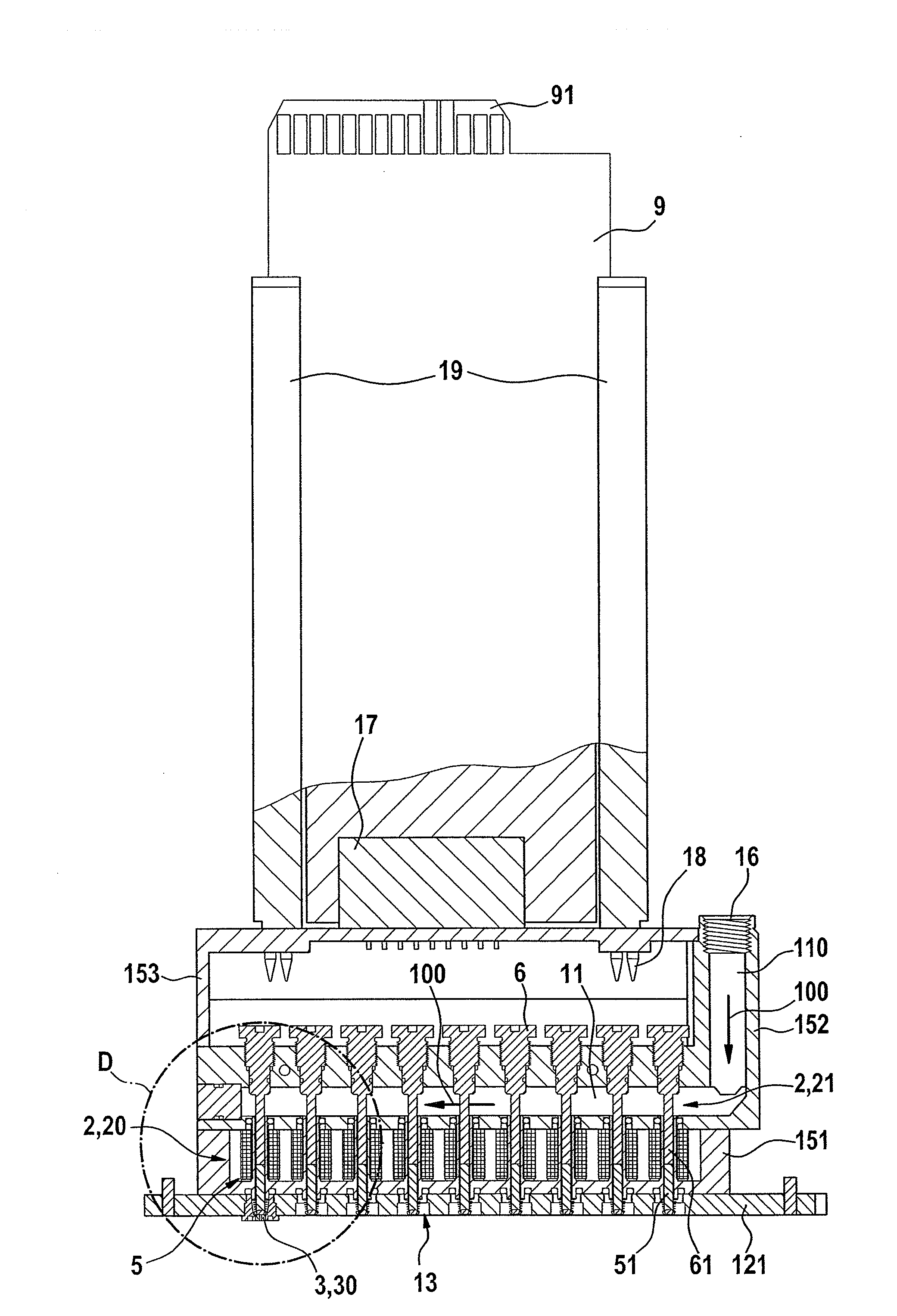

[0027]As can be seen from the sectional view in FIG. 2, the valve body 15 is connected to an electronic power switching device 9. This switching device 9 is connected by mean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com