METHOD OF GROWING PURE Ge THIN FILM WITH LOW THREADING DISLOCATION DENSITY

a thin film, low-density technology, applied in the direction of single crystal growth, polycrystalline material growth, chemistry apparatus and processes, etc., can solve the problems of deterioration of device characteristics, time-consuming process taking almost 4 hours, and leakage curren

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

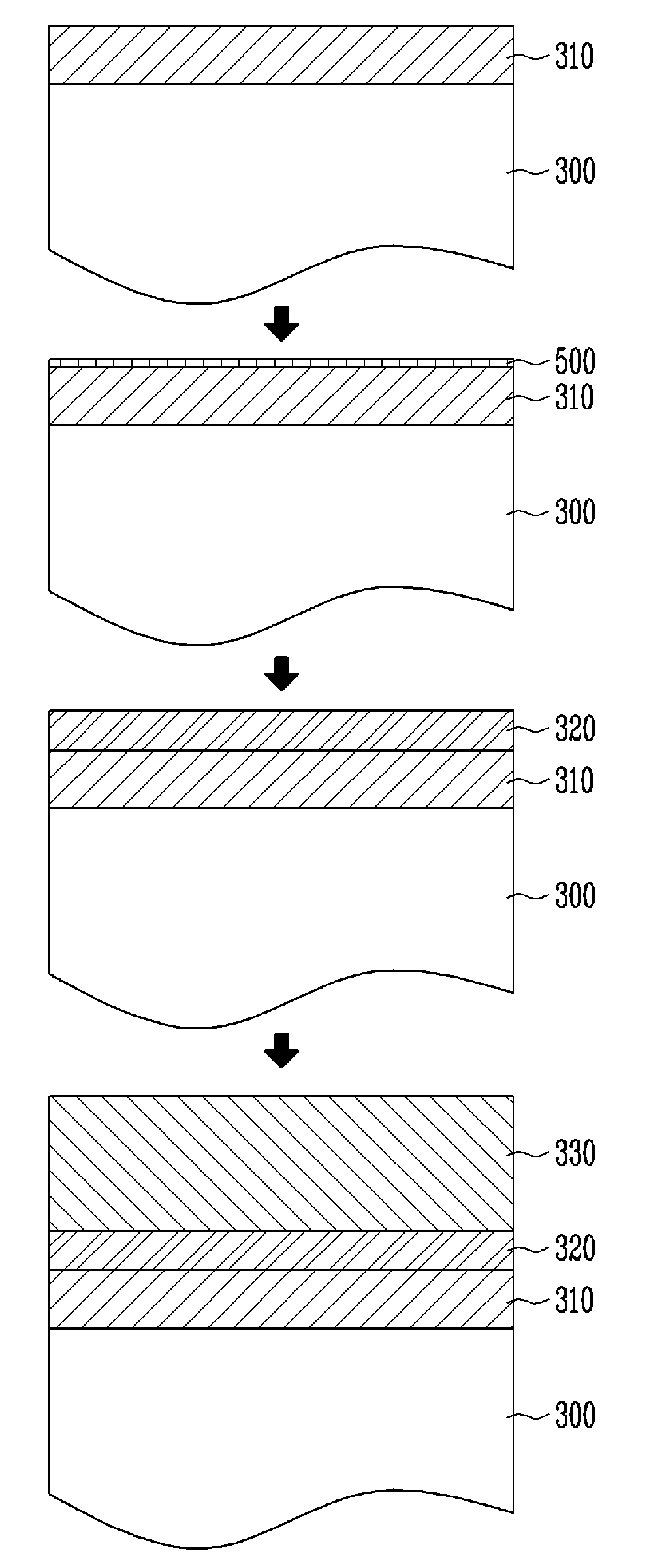

[0044]In RPCVD, GeH4 diluted to 20 vol % with hydrogen was injected to a silicon substrate at a flow rate of 200 sccm under the conditions of 400° C. 15 and 30 torr, and hydrogen gas was injected at a flow rate of 20 slm to grow a Ge thin film to a thickness of 100 nm. Subsequently, in RPCVD, the injection of the GeH4 gas was stopped, a temperature was increased to 875° C. at a rate of 200° C. per minute, and annealing was performed for 10 minutes. After annealing, the temperature was decreased at the same rate at which it was increased, 200° C. per minute, and the GeH4 gas was injected at a flow rate of 40 sccm under the conditions of 700° C. and 80 torr to grow the Ge thin film to a thickness of 1400 nm.

experimental example

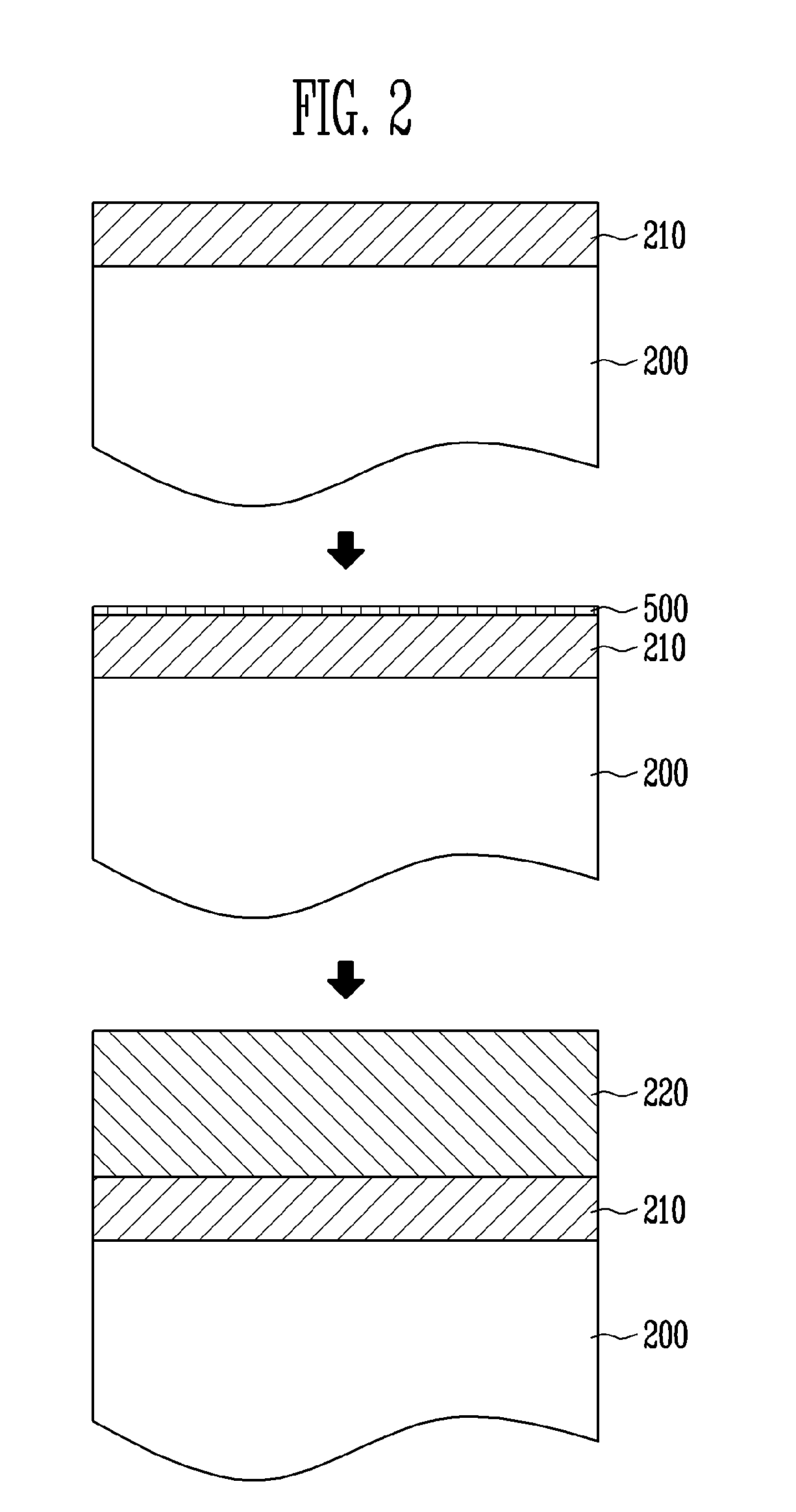

[0045]Analysis of Ge Concentration after Annealing

[0046]After real-time annealing the Ge thin film having a thickness of 100 nm grown at a low temperature according to Example 1, the Ge concentration was obtained through SIMS analysis, and the result is shown in FIG. 4.

[0047]As shown in FIG. 4, the low-temperature Ge thin film grown over the silicon substrate was changed into a Si—Ge thin film (Si0.16Ge0.84) having a Ge content of 84 at % on its surface by gradually increasing the Ge content through annealing.

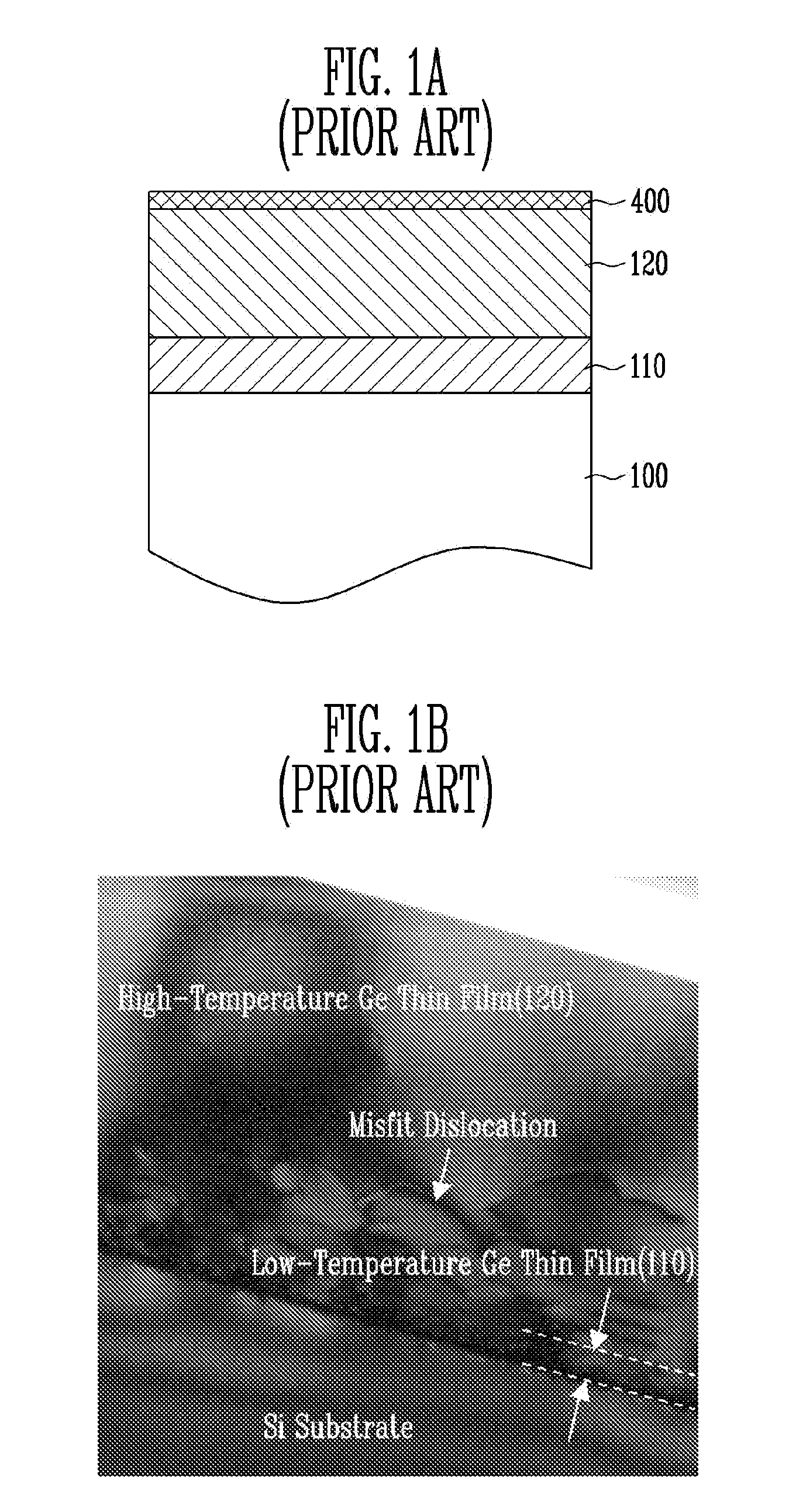

[0048]Analysis of Ge Concentration of Ge Single Crystal Thin Film

[0049]The Ge concentrations of the Ge single crystal thin film formed using RPCVD according to Example 1 and the conventional Ge thin film (shown in FIG. 1) formed using UHVCVD were obtained through SIMS analysis, and the result is shown in FIG. 5. As shown in FIG. 5, the conventional Ge thin film was changed into a Si—Ge layer whose thickness was ⅓ of the overall thickness. The Si—Ge layer was formed by interdiff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com