Device and method for preparing high-quality large-diameter SiC single crystal

A preparation device and large-diameter technology, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of threading dislocation density reduction, diameter expansion hindering the bottleneck of large-diameter SiC crystal growth, diameter expansion failure, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

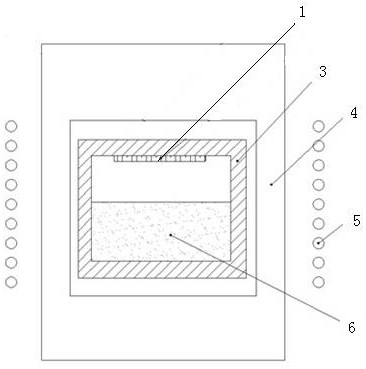

[0044] A method for preparing a high-quality large-diameter SiC single crystal using the above-mentioned preparation device includes the following steps:

[0045] (1) Fixing the seed crystal between the lower surface of the crucible top cover and the upper surface of the crucible bottom;

[0046] (2) Fill the SiC raw material in the hollow interlayer between the crucible and the porous graphite barrel;

[0047] (3) Vacuum so that the vacuum degree in the crucible is less than or equal to 10 -4 Pa, through the inert gas to a pressure of 100Kpa;

[0048] (4) Start the heating device, take the contact point between the seed crystal and the top cover of the crucible as the temperature measurement point, heat up to the temperature of the temperature measurement point at 1800-2200°C, reduce the pressure to 500-2000Pa, and make the gap between the porous graphite barrel and the crucible The SiC raw material is sublimated, and the sublimated Si and C components are driven by the rad...

Embodiment 1

[0051] 1. The crucible of isostatic graphite is used as a heat source for induction heating;

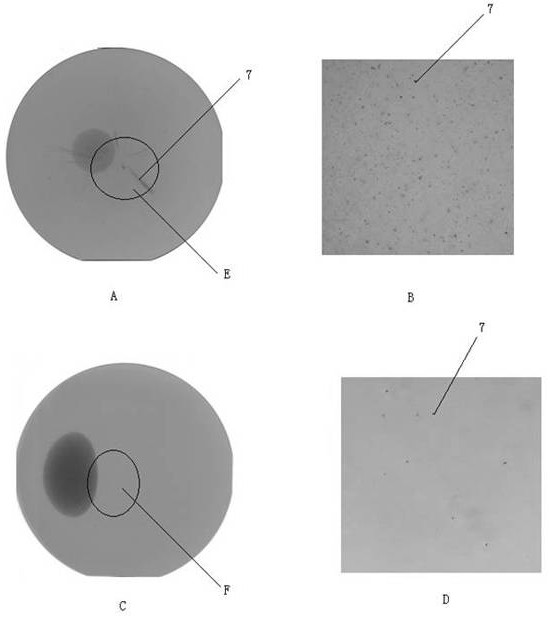

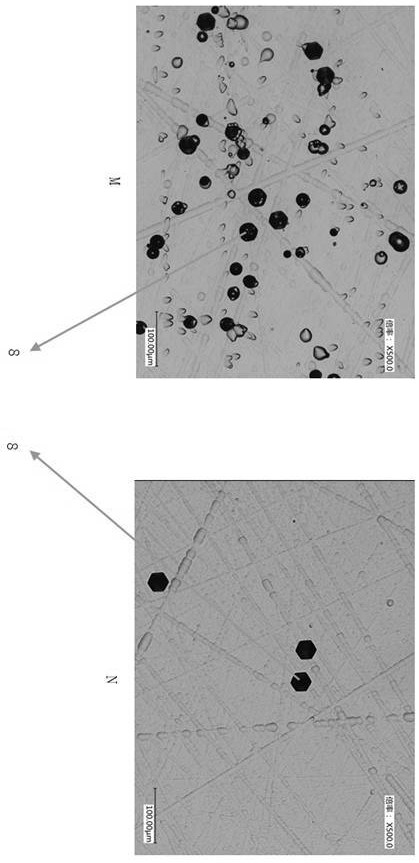

[0052] 2. There is a round rod-shaped SiC seed crystal fixed in the middle of the crucible, and the SiC seed crystal is cut from the crystal grown by the traditional PVT method in the (0001) direction;

[0053] 3. The porous graphite barrel is located in the crucible and is coaxial with the crucible; the SiC raw material is loaded into the hollow interlayer between the crucible and the porous graphite barrel;

[0054] 4. Graphite soft felt acts as an insulation layer and surrounds the crucible to prevent heat loss and form a radial temperature difference between high outside and low inside;

[0055] 5. The outermost periphery is a Cu induction coil, which is used to generate an electromagnetic field to heat the crucible. In order to make the different positions of the side wall of the crucible heat evenly, the induction coil is a combination of discrete multi-strand coils;

[0056] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com