Fan blades

a technology of blades and axial fans, applied in the direction of liquid fuel engine components, pump components, non-positive displacement fluid engines, etc., can solve the problems of increasing increasing dust, and settling a great deal of dust, so as to reduce power consumption and noise, reduce pressure differences, and eliminate backflow phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

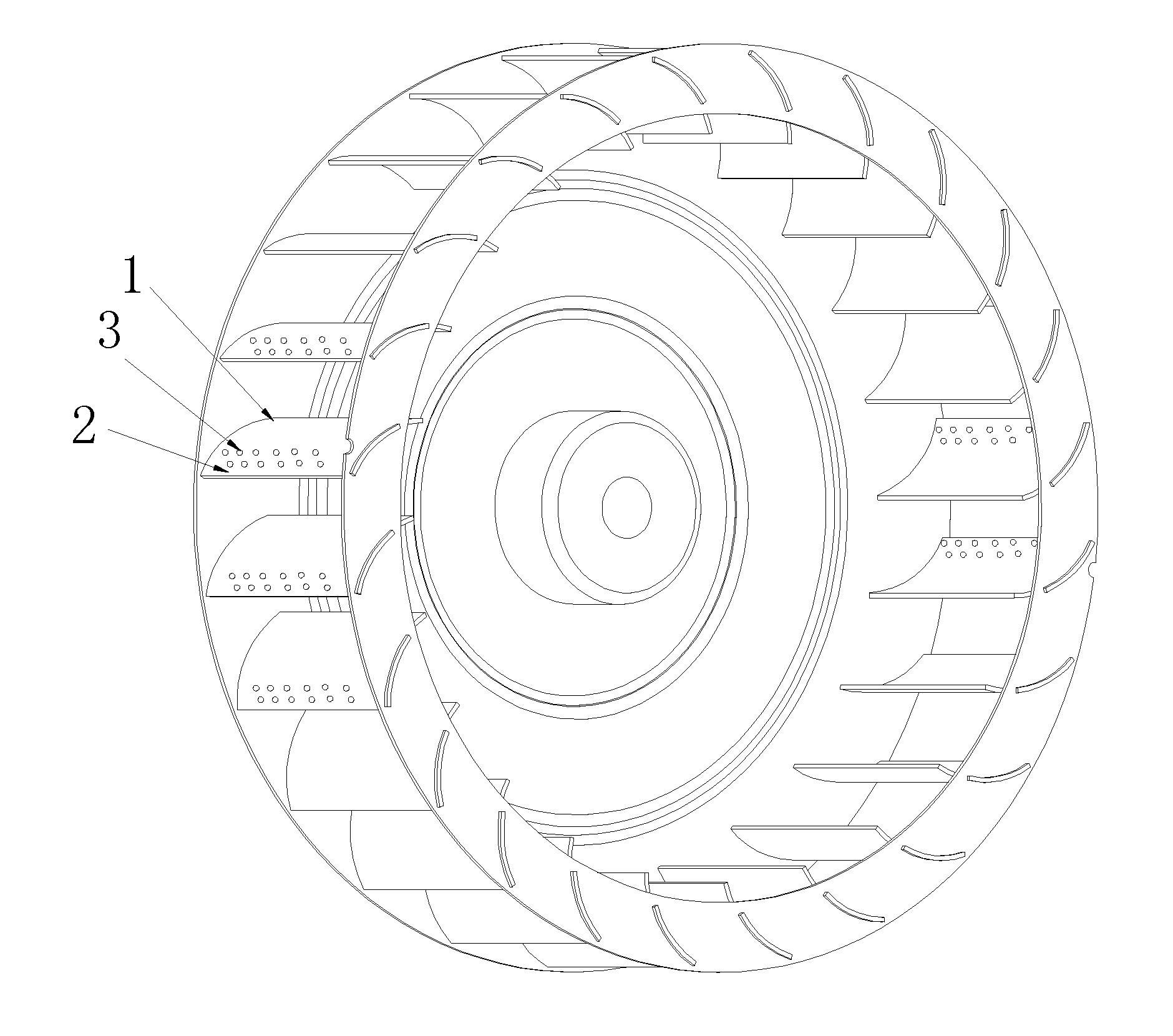

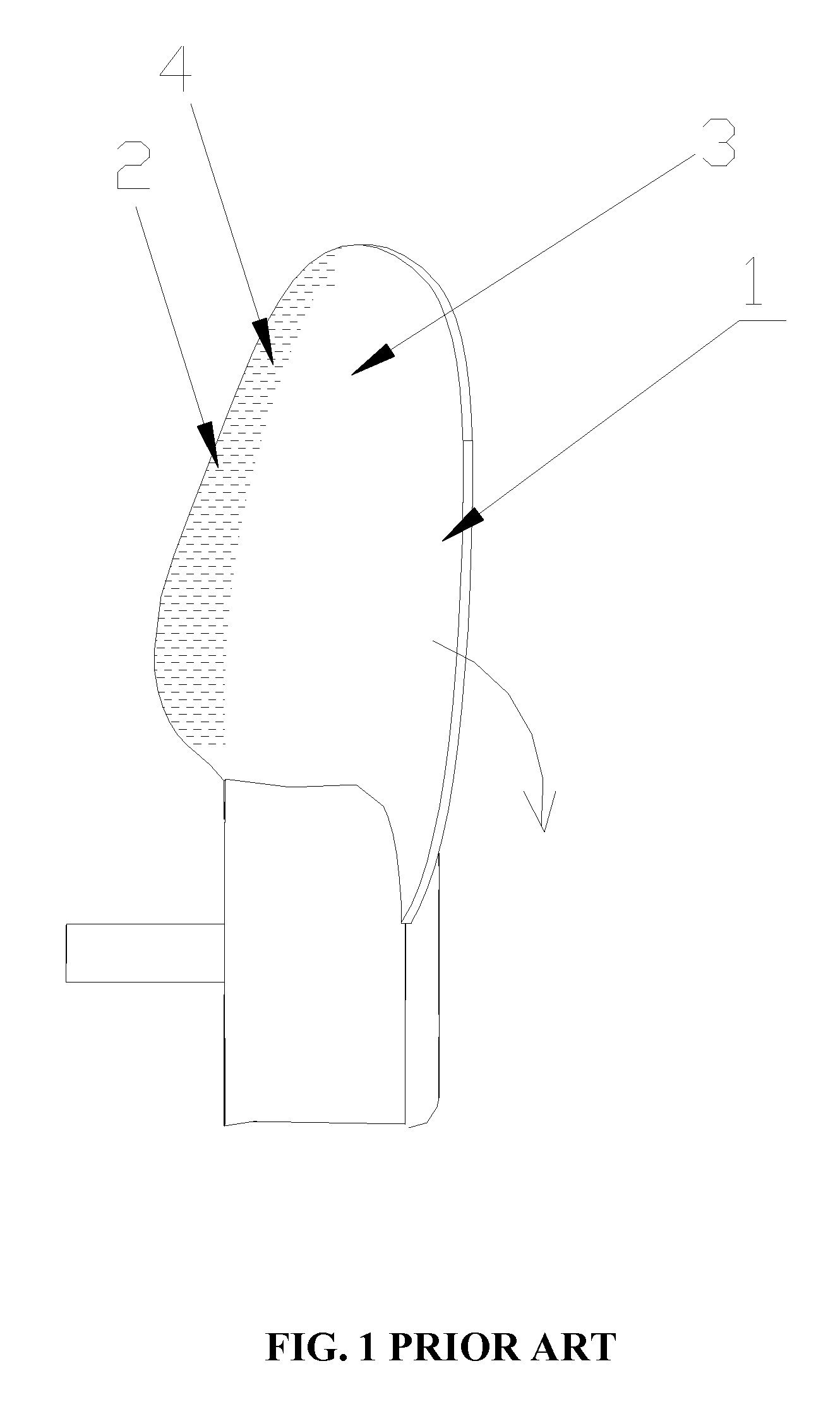

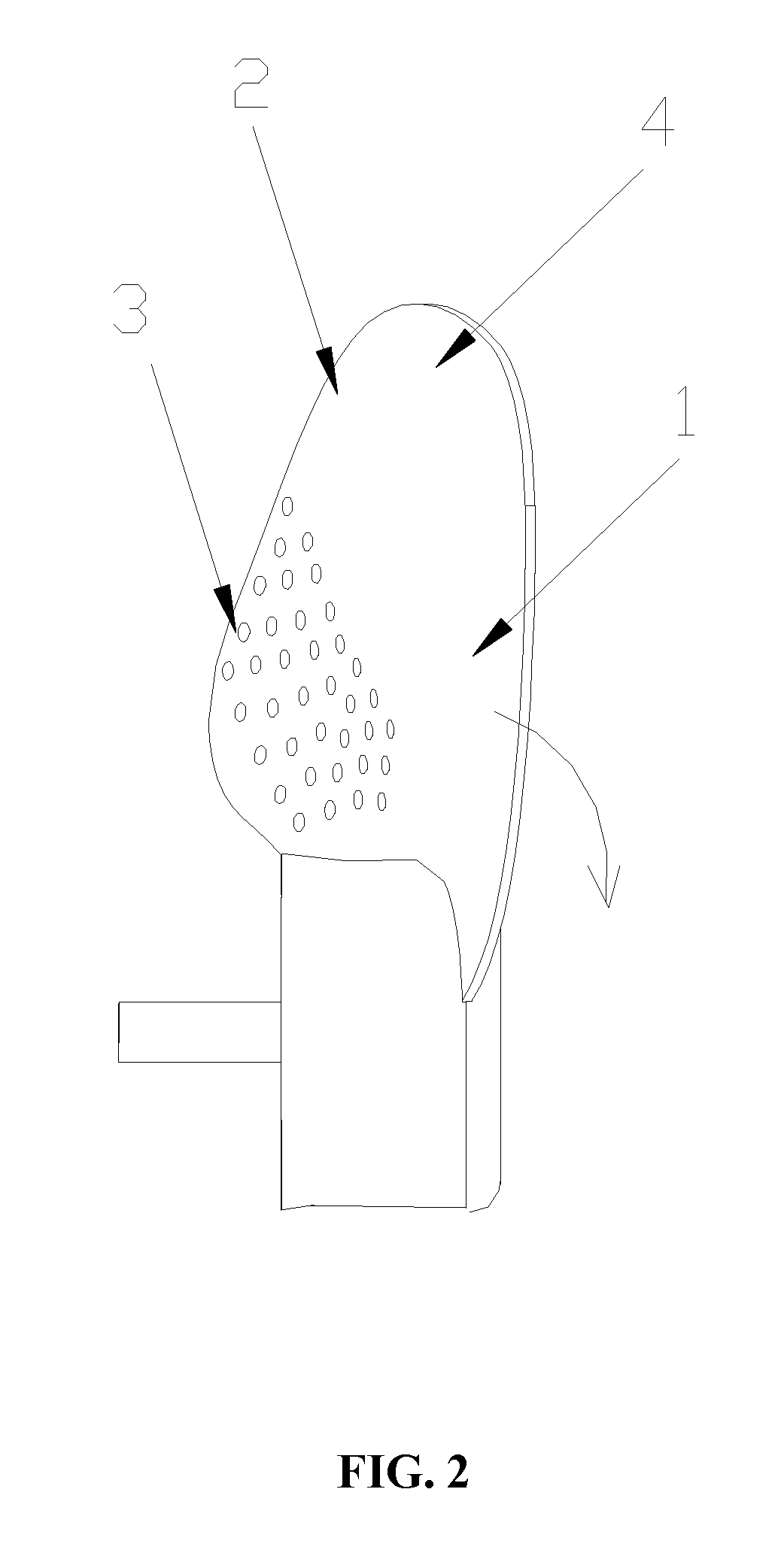

[0029]As shown in FIGS. 2 and 3, a blade for an axial fan of the invention comprises a front edge portion 1, a back edge portion 2, and multiple pressure balance holes 3. The front edge portion 1 operates to blow air from the outside of the blade, the back edge portion 2 operates to blow air to the outside of the blade, and the pressure balance hole 3 is disposed on the back edge portion 2.

[0030]The pressure balance holes 3 are distributed in an array, uniformly or randomly.

[0031]In this embodiment, the pressure balance holes 3 are circular holes, non-circular holes, straight through holes or inclined through holes, and a diameter of each of the pressure balance holes 3 ranges from 0.1 mm to 100 mm.

[0032]The pressure balance holes 3 form a hole net whereby adjusting pressure on both side of the blade.

[0033]The pressure balance holes 3 are capable of balancing pressure and reducing pressure difference between a front side and a back side of the blade, eliminating a backflow phenomena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com