Process for online power cut out of an aluminum reduction cell

a technology of aluminum reduction cell and aluminum reduction, which is applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of increasing the duration of the power cut, unnecessary stress in the turbine & related equipment, tube leakage, etc., and achieves the stability of the operating pot, the effect of increasing production and eliminating frequent power outages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

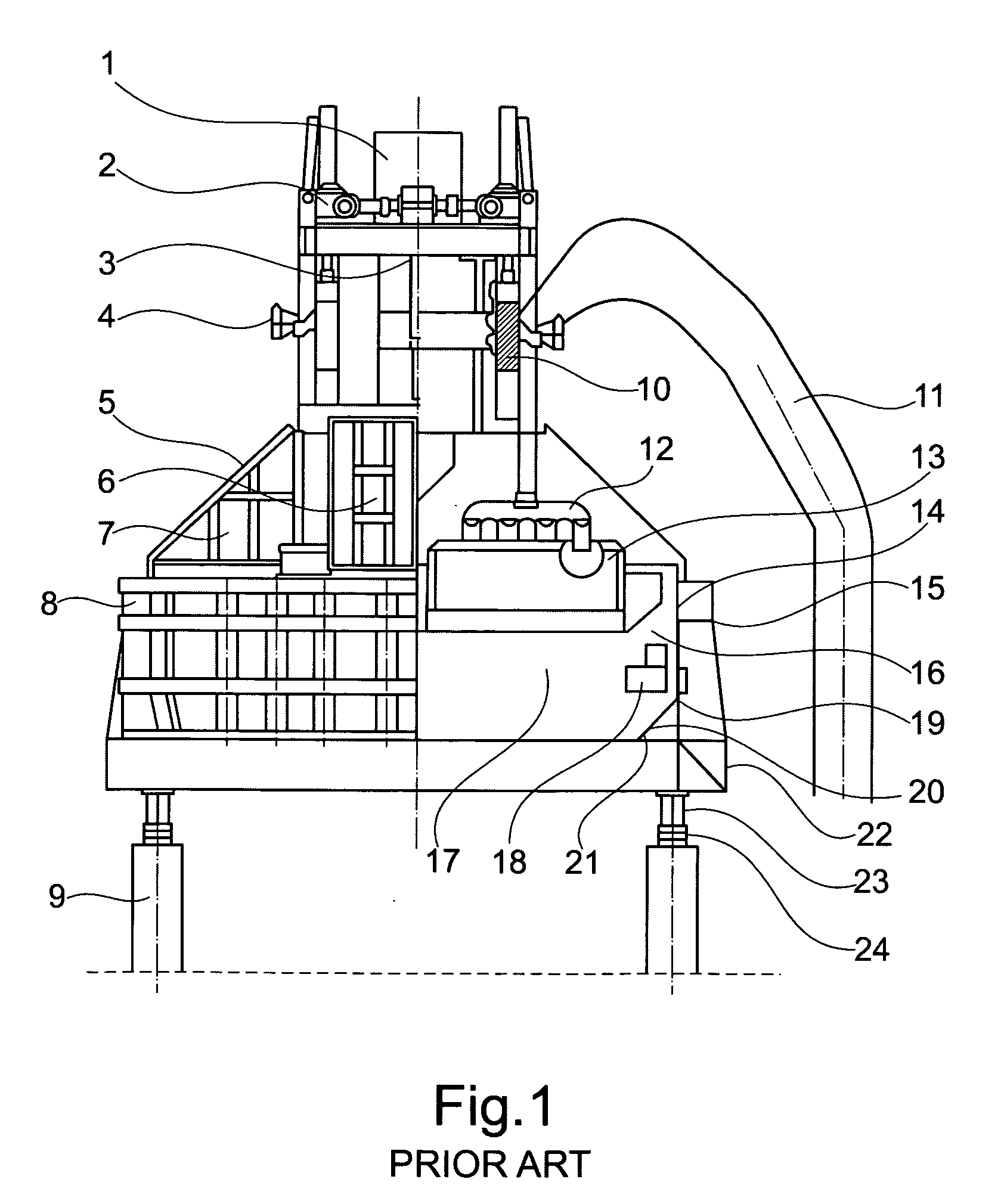

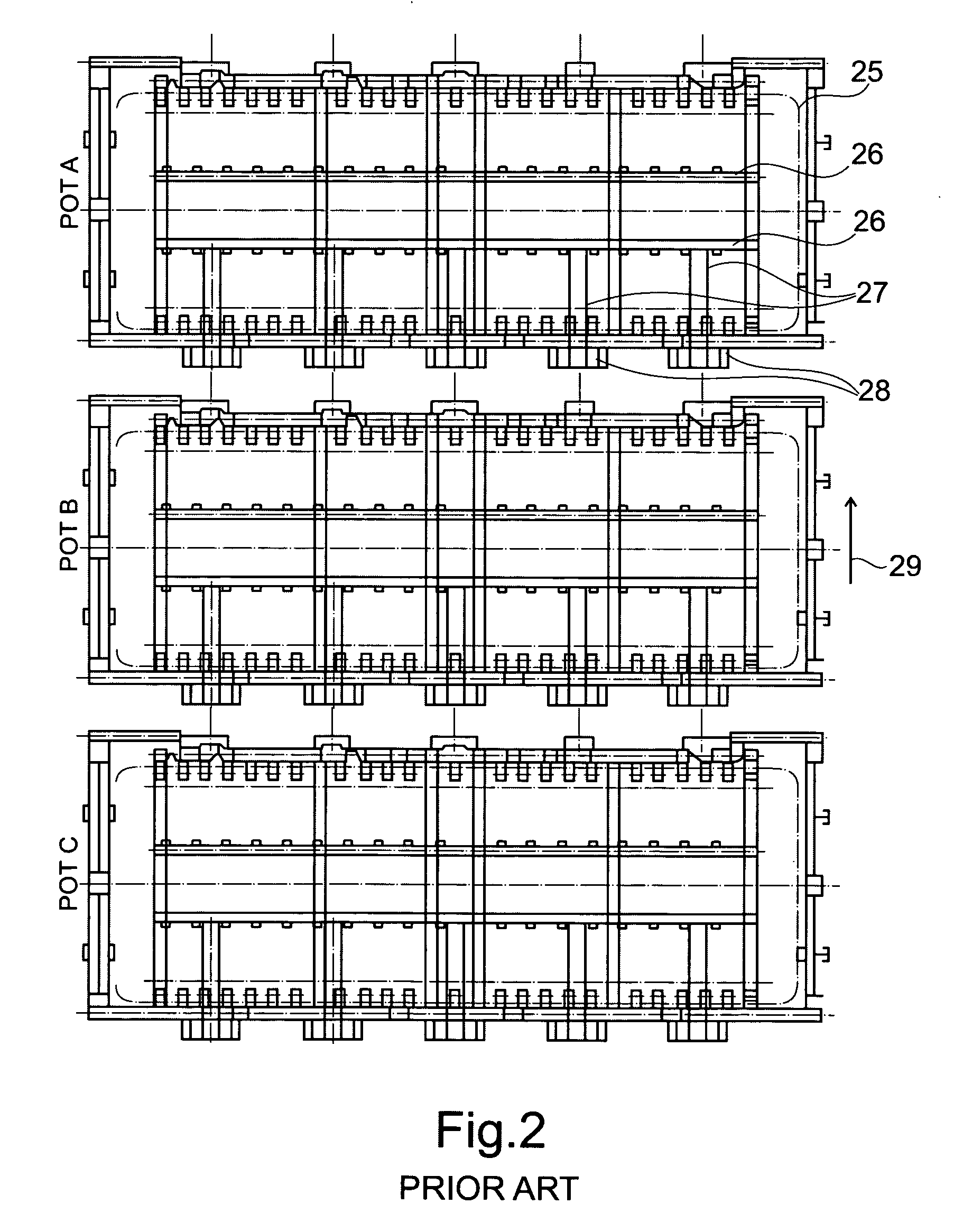

[0042]A typical GP 320 Aluminum reduction cell known in the art is shown in FIG. 1. This pot shell assembly consists of pot super structure and pot shell. The pot super structure houses alumina hopper (1) for feeding alumina, an anode jack (2) for the anode bus bar movement, an anode bus bar (10), crust breaking device (3) to punch holes in the crust for alumina feeding and pot covers. Current flows from risers (11) to the anode bus bar (10). There are around 40 anodes clamped to the anode bus (10) bar with anode clamps (4) through which current flows through the bath.

[0043]The pot shell includes pot lining material like Calcium Silicate Bricks (21), Insulating Bricks ((20), Dry Impervious material (19), castable (18), SiC bricks (14) and side carbon bricks (15). Cathode blocks (17) are placed over the dry impervious material (19). The whole pot shell assembly is placed over civil columns (9) with proper insulation (24).

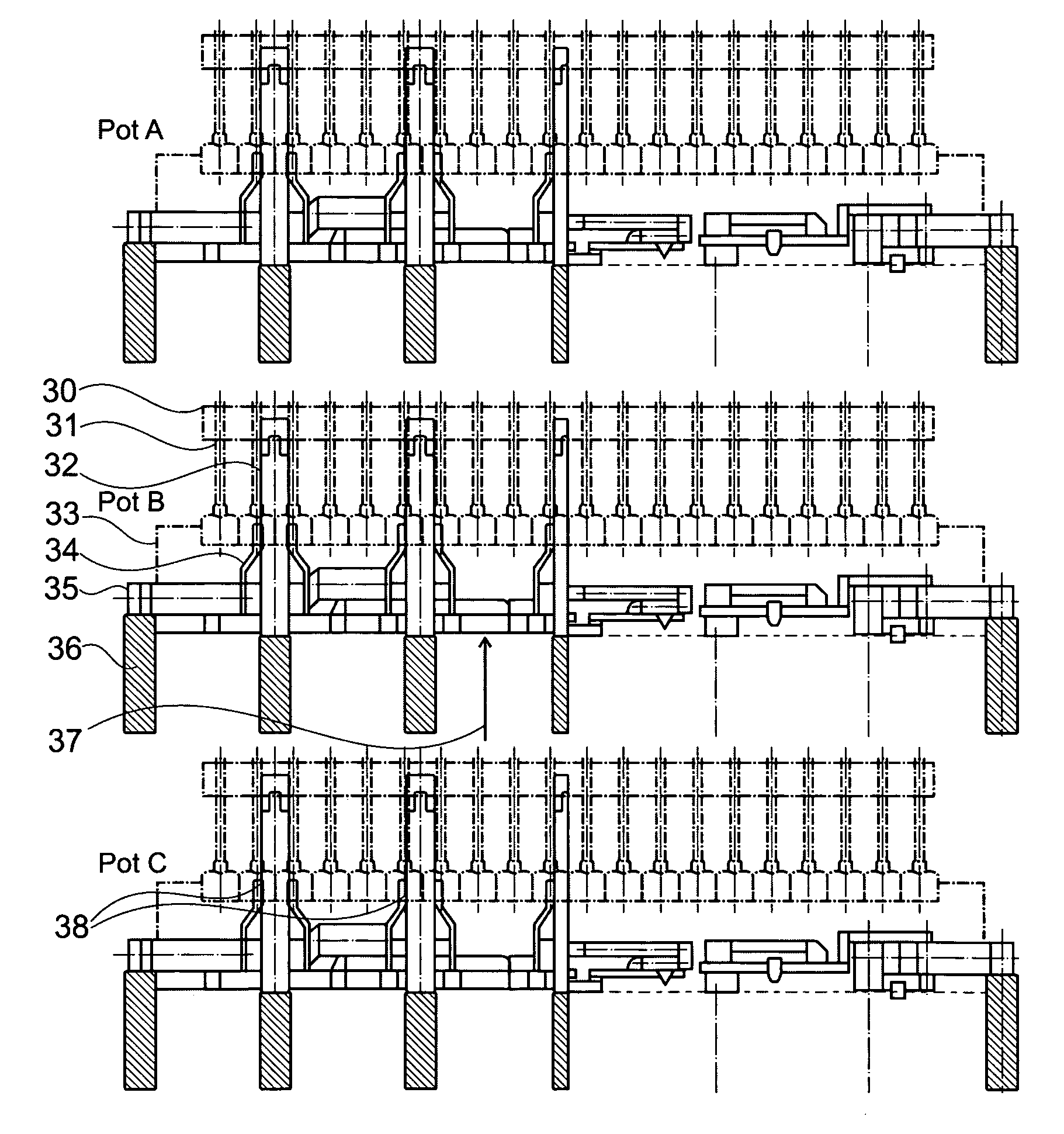

[0044]The earlier technology proposed by GAMI to a take a pot o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com