Retortable Closures and Containers

a technology of retortable and/or sterilizable containers and closures, which is applied in the direction of sealing, packaging, closure caps, etc., can solve the problems of high-sterilized product containers that may have very long shelf life, may become contaminated and/or spoil, and may have adverse effects on such products, etc., to achieve the effect of less manufacturing cost and higher degree of sterility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

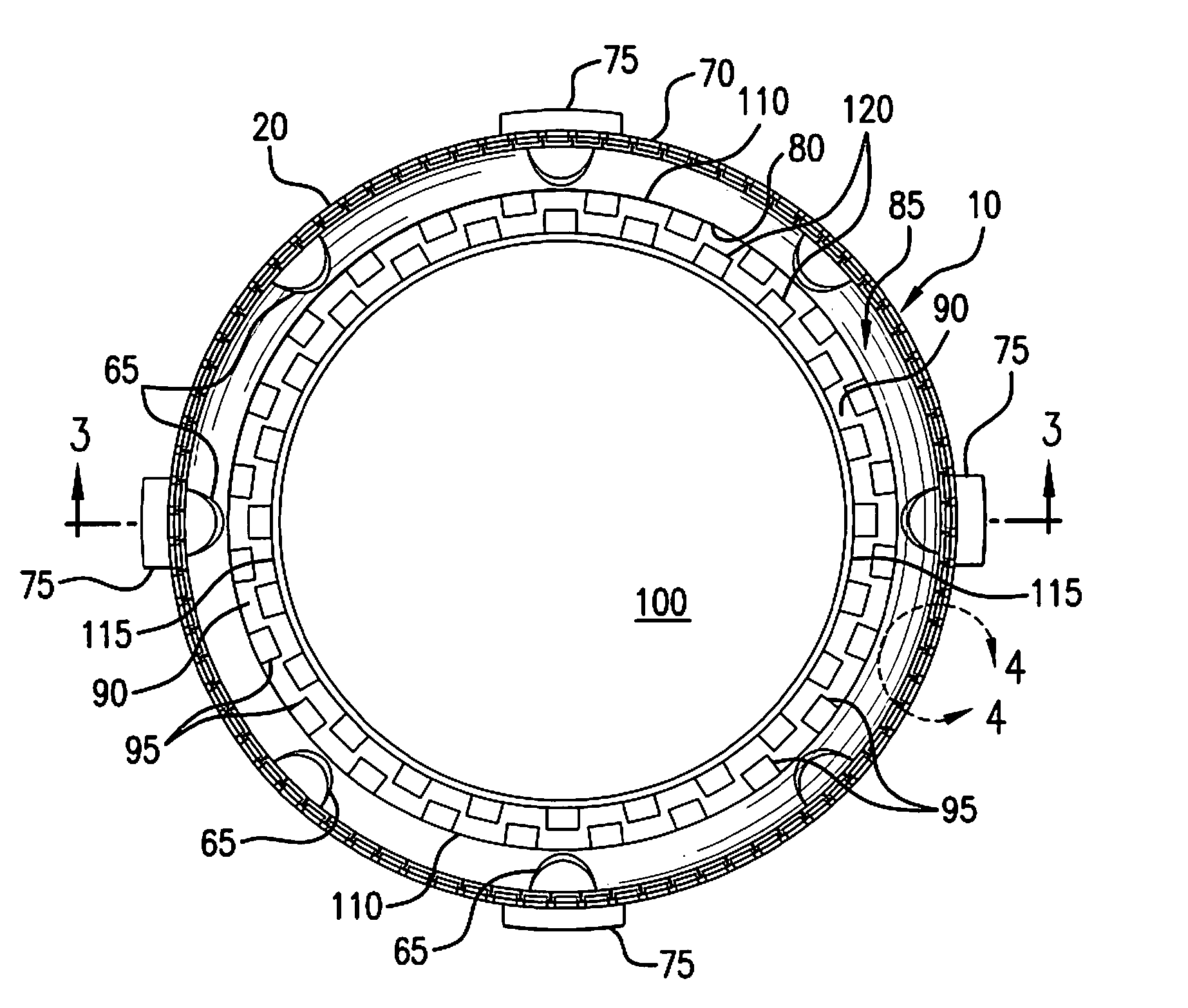

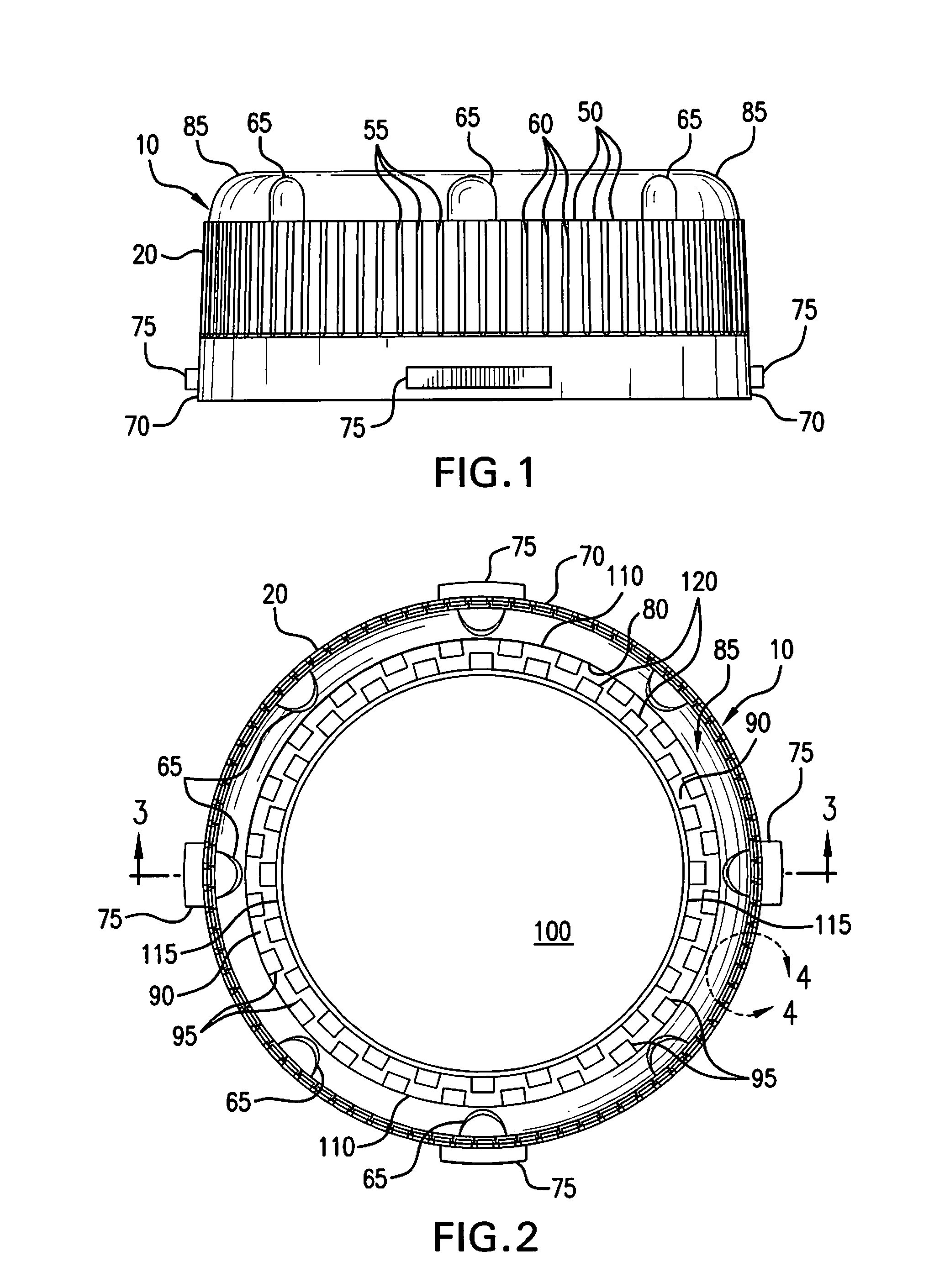

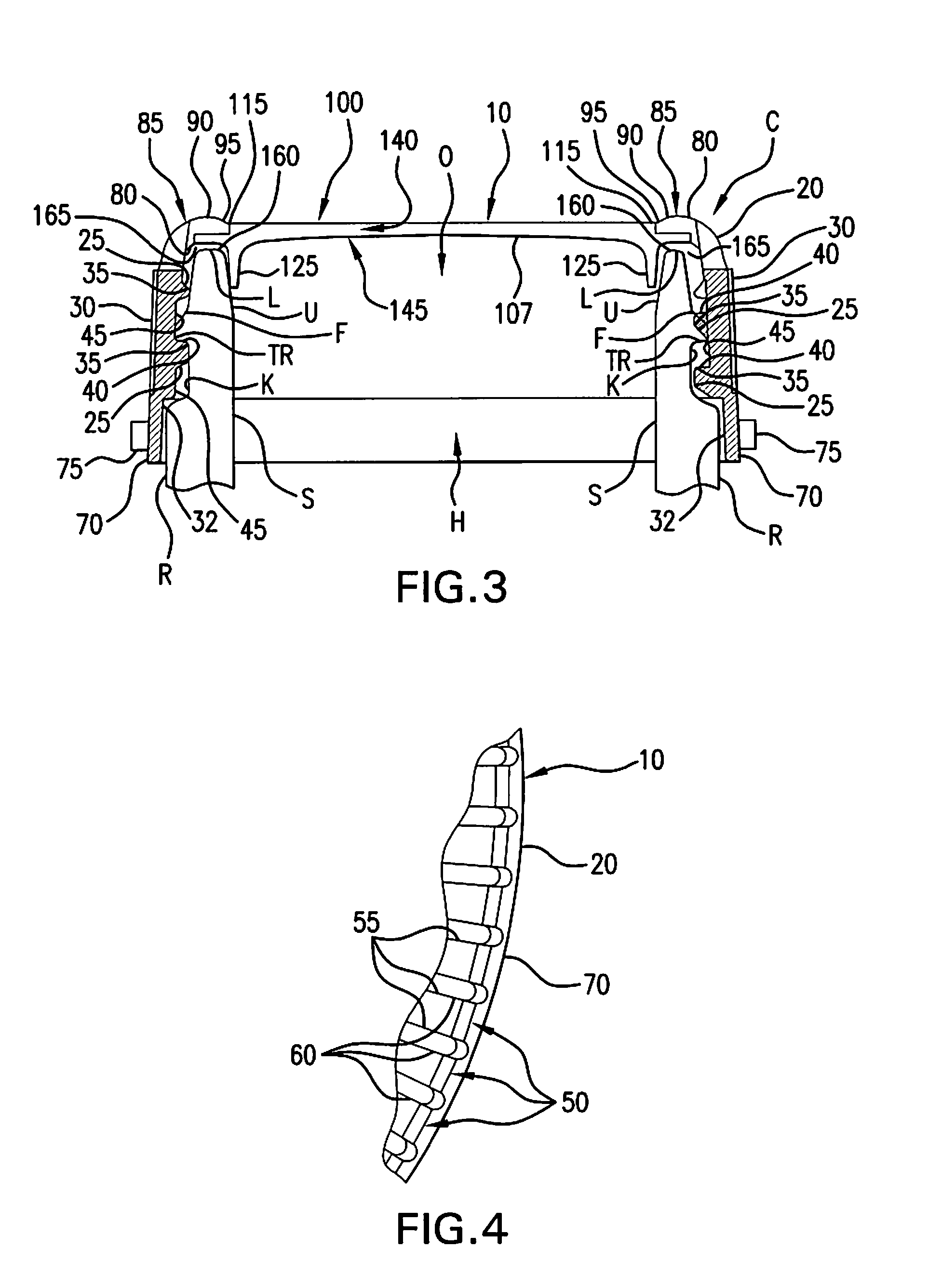

[0037]Referring now to the various figures and illustrations, those skilled in the relevant arts should appreciate that each of the preferred, optional, modified, and alternative embodiments of the inventive retortable container C and retortable closures 10 contemplate interchangeability with all of the various features, components, modifications, and variations within the scope of knowledge of those skilled in the relevant fields of technology and that are described throughout the written description, claims, and pictorial illustrations herein. Additionally, the many various alternative arrangements, optionally preferred modifications, and possible variations of the preferred embodiments of the invention may be used in part and in any conceivable combination, which may be particularly desired and / or of benefit for certain applications and uses.

[0038]With these guiding concepts in mind, and with reference now to FIGS. 1, 2, and 3, one possibly preferred embodiment of a retortable cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com