Method for treating waste containing precious metals and device for implementing said method

a precious metal and waste technology, applied in the field of precious metal treatment waste, can solve the problems of poorly adaptable to producing rare and precious metals in small amounts, and generate an increasing amount of waste containing rare and precious metals, and achieve the effect of reducing the carrying away of precious metals by metal oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073]The invention is now described in more detail and in a non-limiting way in the following description.

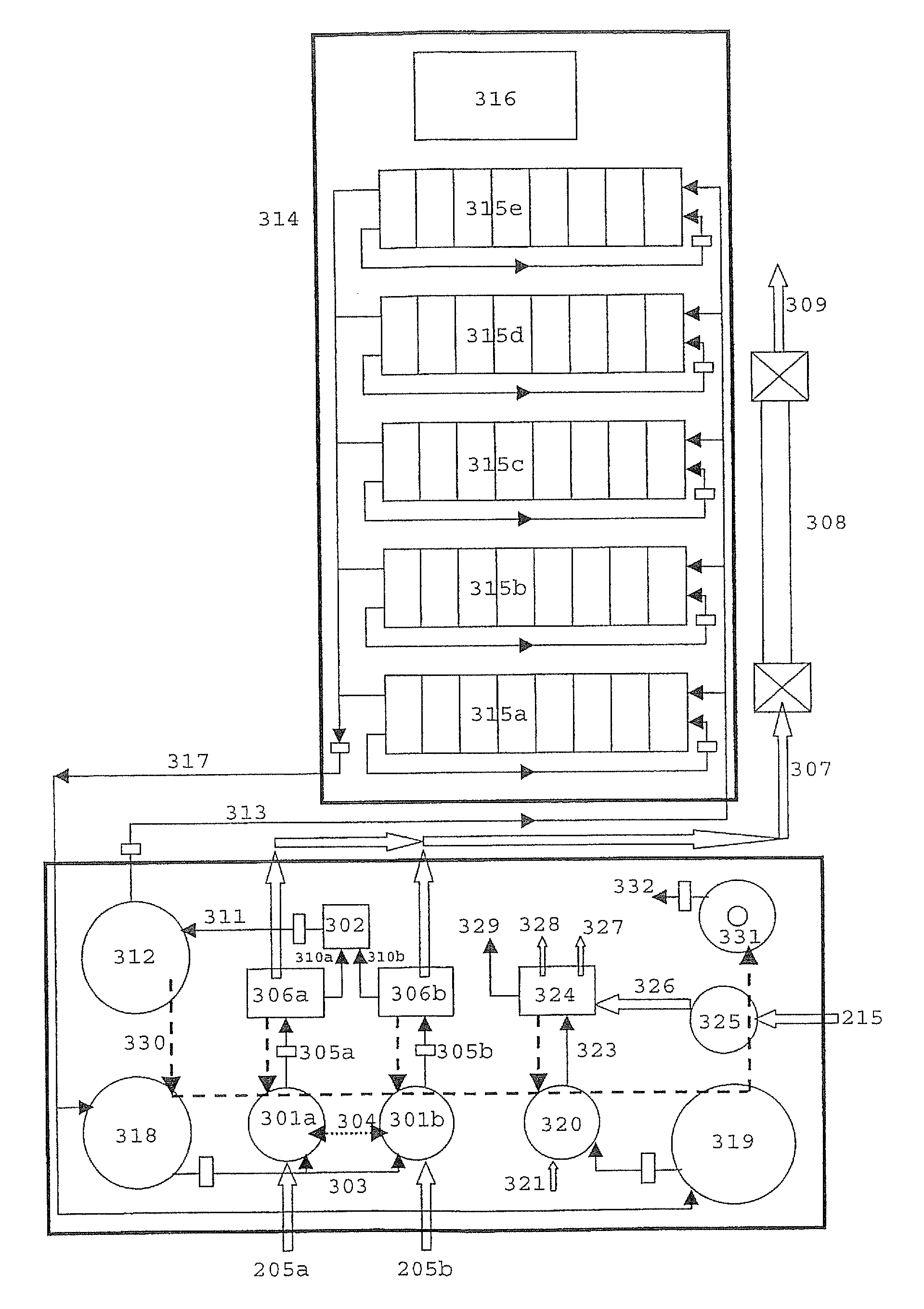

[0074]Waste Treatment Installation

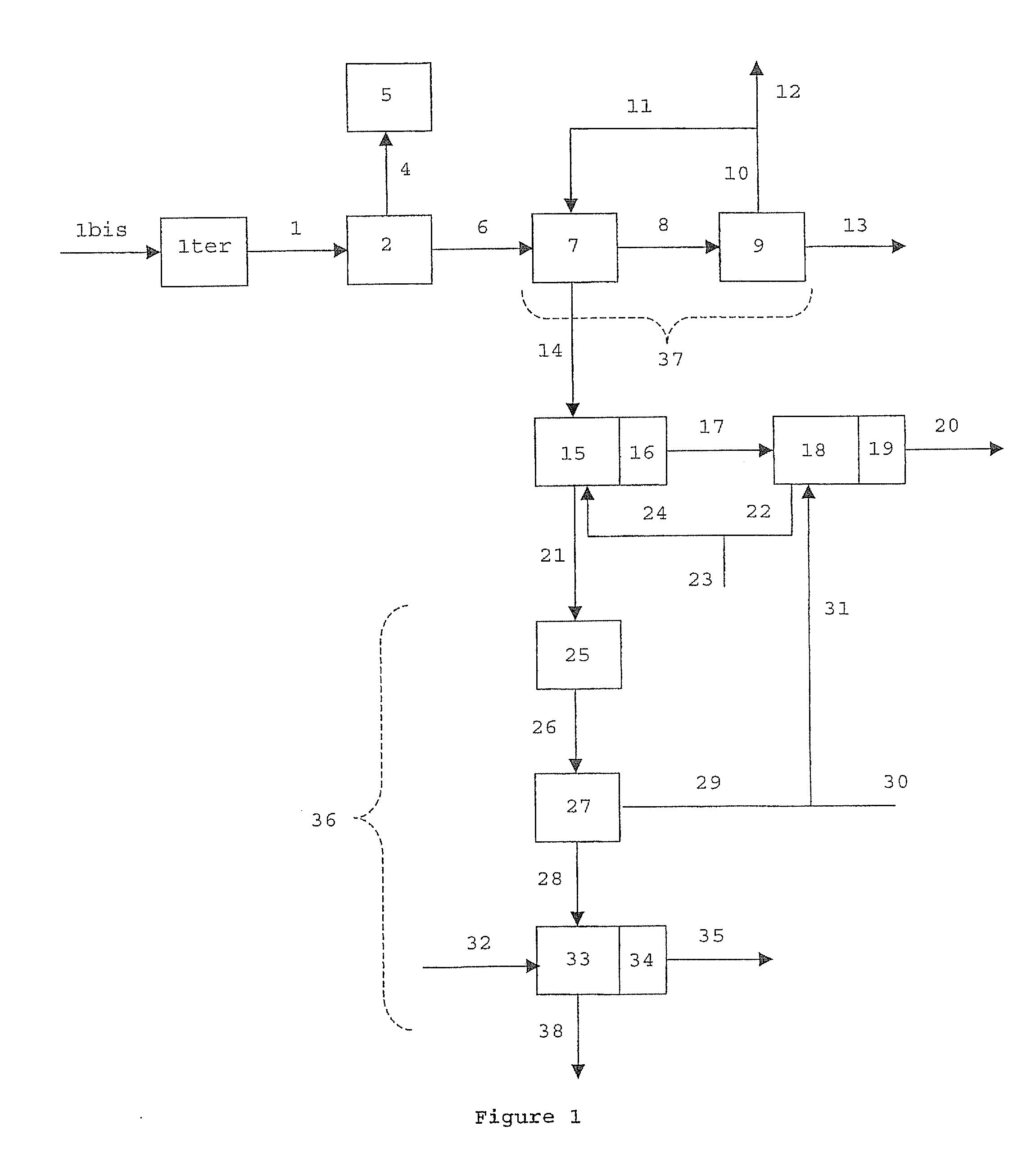

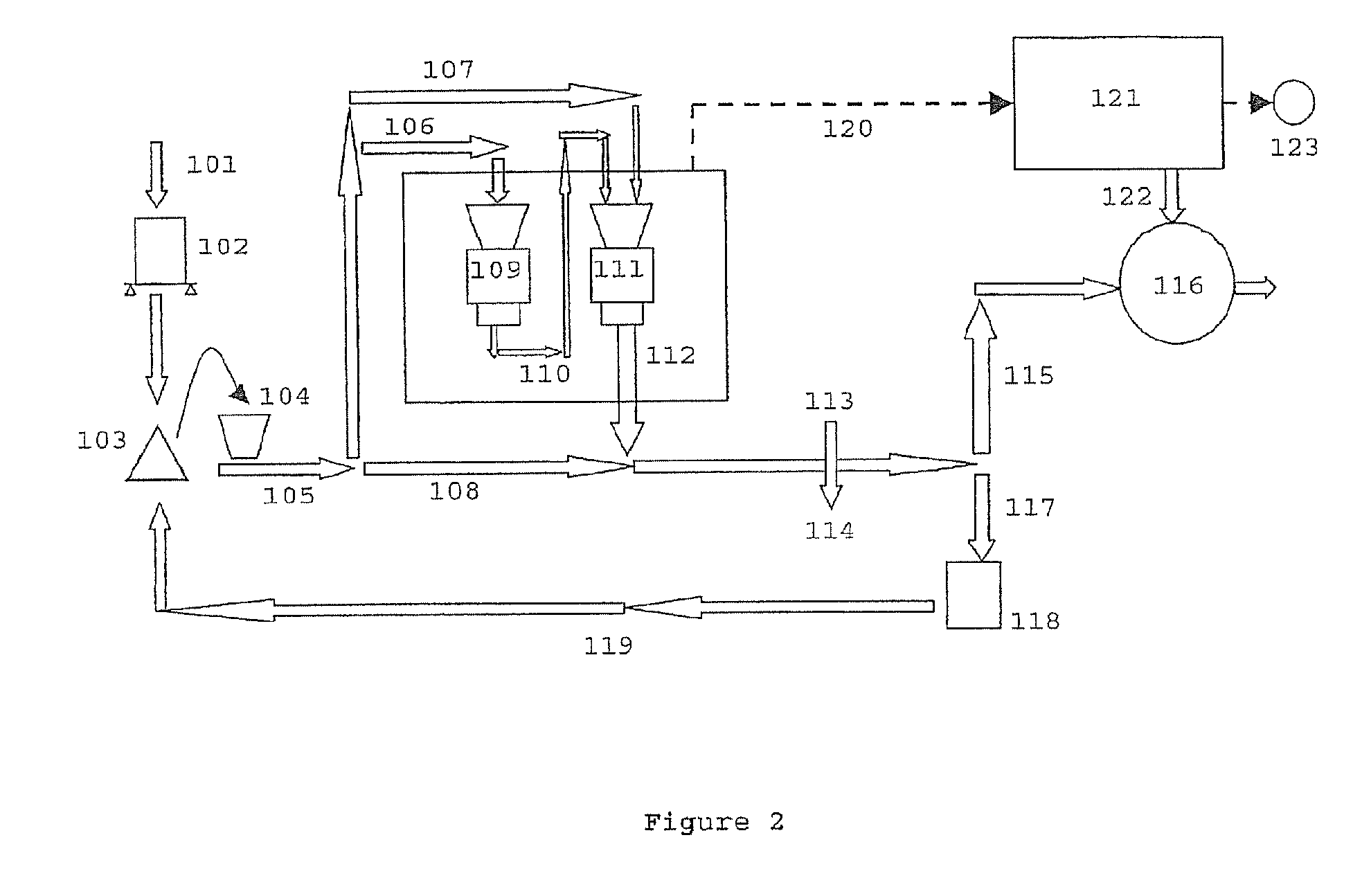

[0075]Referring to FIG. 1, an installation for treating waste according to the invention schematically comprises the following components. Provision is made for a waste feed line 1 at the entry of the treatment installation. This waste feed line 1 may optionally be connected to the outlet of the milling and analysis means 1ter fed by a raw waste feed line 1bis. The waste feed line 1 like all the other feed, transfer or withdrawal lines mentioned in the present description may include a single route or several routes (branches) in parallel.

[0076]According to an embodiment, the waste feed line 1 feeds pyrolysis means 2. At the outlet of the pyrolysis means 2, provision is made for means for feeding primary materials 6, which feed copper extraction means 37. At the outlet of the copper extraction means 37, provision is made for a pre-treated mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com