Thermally Conductive Composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

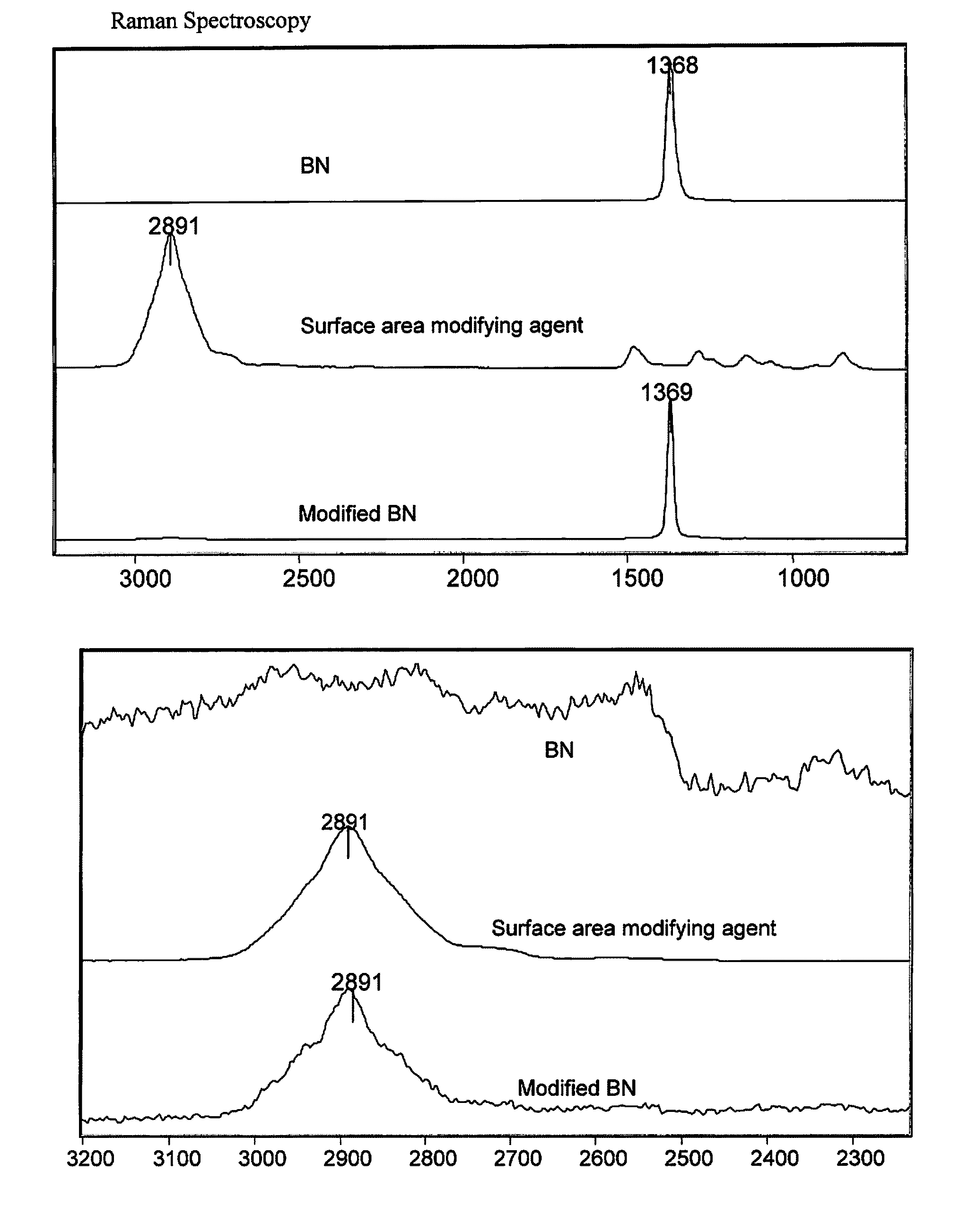

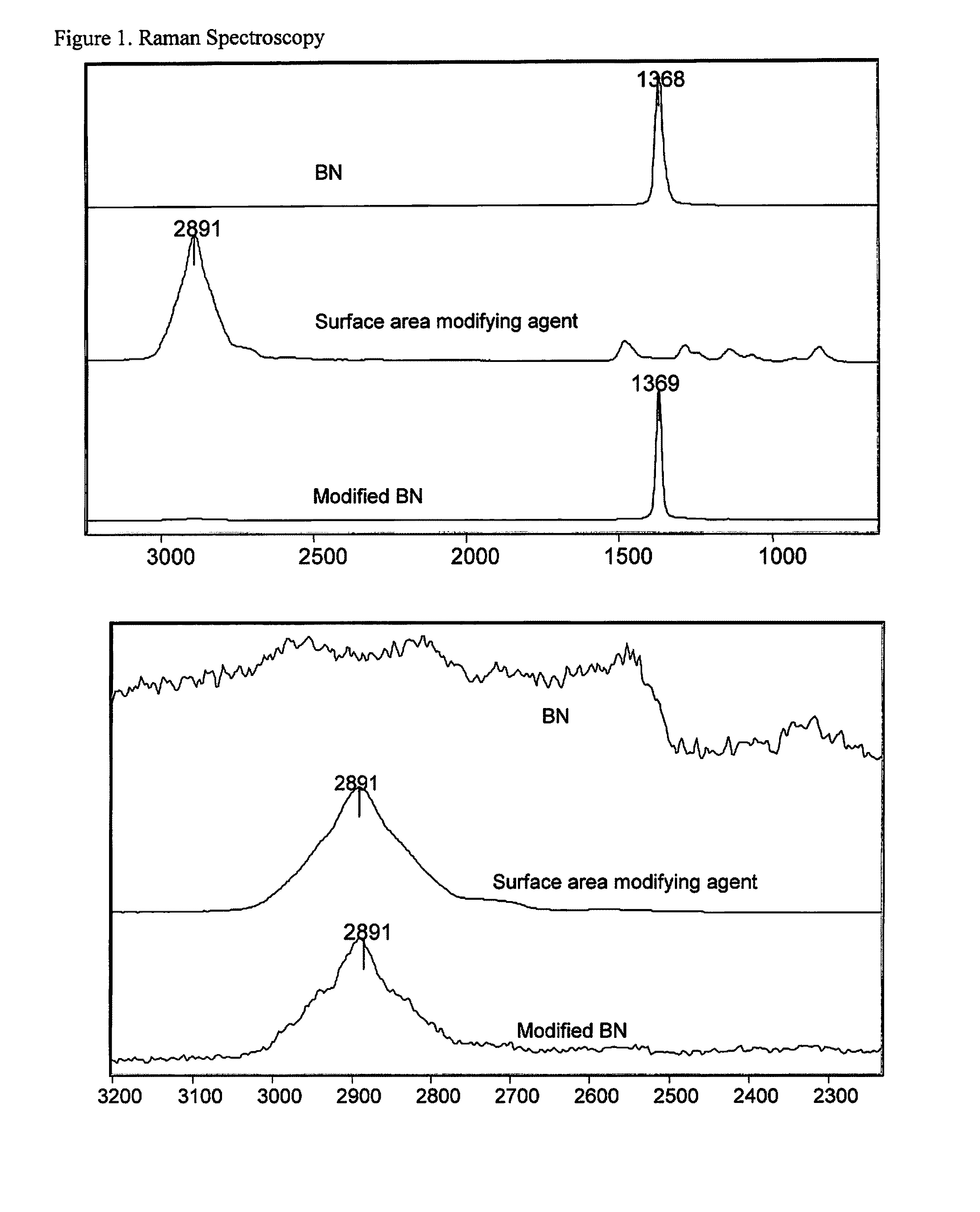

Physical Treatment of Filler with Surface Area Modifying Agent

[0046]Two different methods of physically treating fillers with a surface area modifying agent have been described.

example 1a

Solution Method

[0047]Nine grams of Pluronic F38 (EO-PO block copolymers with —OH terminations, Mw=4700 g / mol, available from BASF) was dissolved into 200 mL of water. Into the Pluronic F38-water solution, 91 g of boron nitride fillers (PTX60, available from Momentive Performance Inc., OH) were dispersed. The water was then evaporated with constant stirring and vacuum overnight. The resultant dry powder weighed 100 g.

example 1b

Fluidization Method

[0048]Nine grams of Pluronic F38 (EO-PO block copolymers with —OH terminations, Mw=4700 g / mol, available from BASF) was dissolved into 45 mL of water. The Pluronic F38-water solution and 91 g of boron nitride fillers (PTX60) were placed in a fluid bed coater (Model MFL.01 by Vector Corporation, IA) to physically treat the fillers. The resultant dry powder weighed 100 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com