Scroll compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

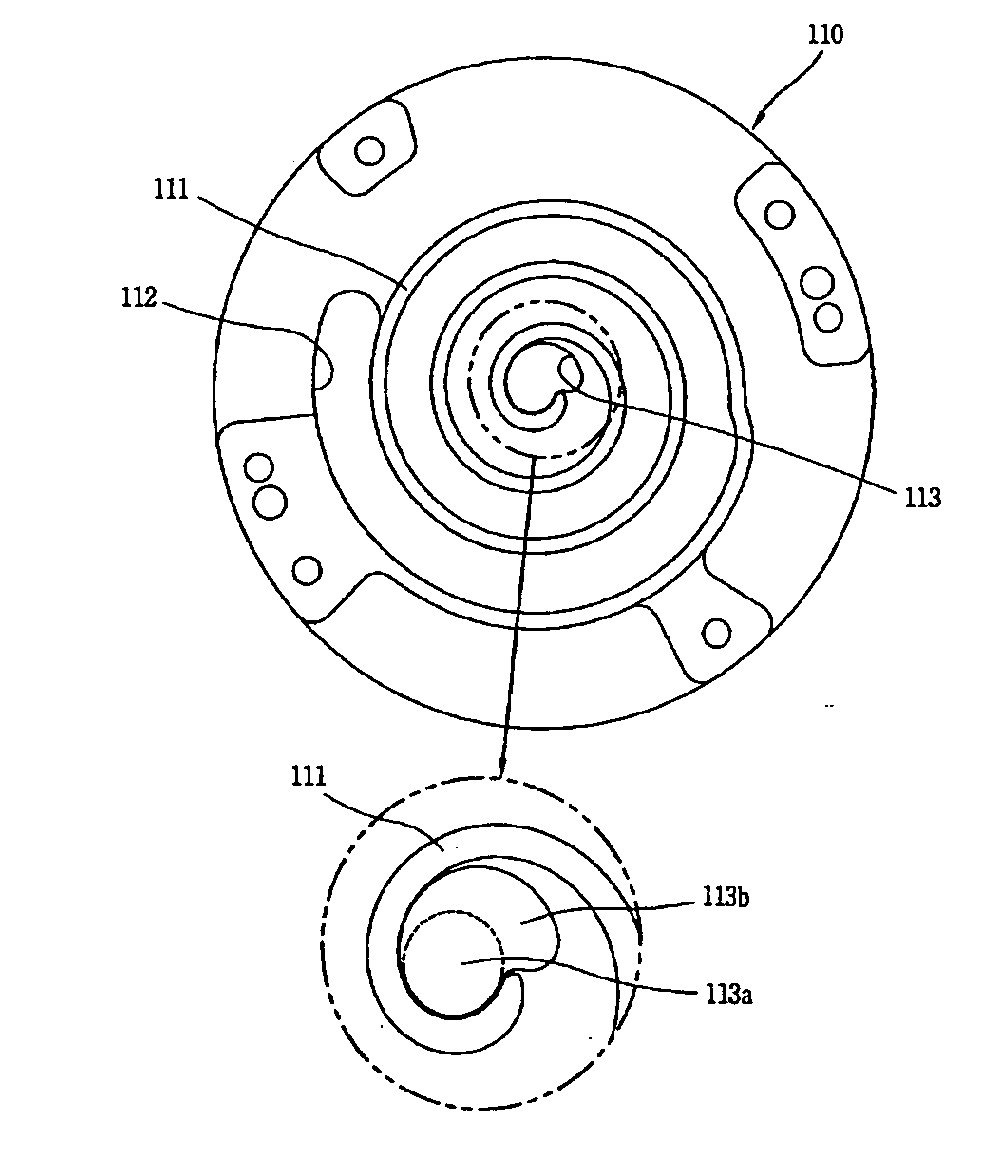

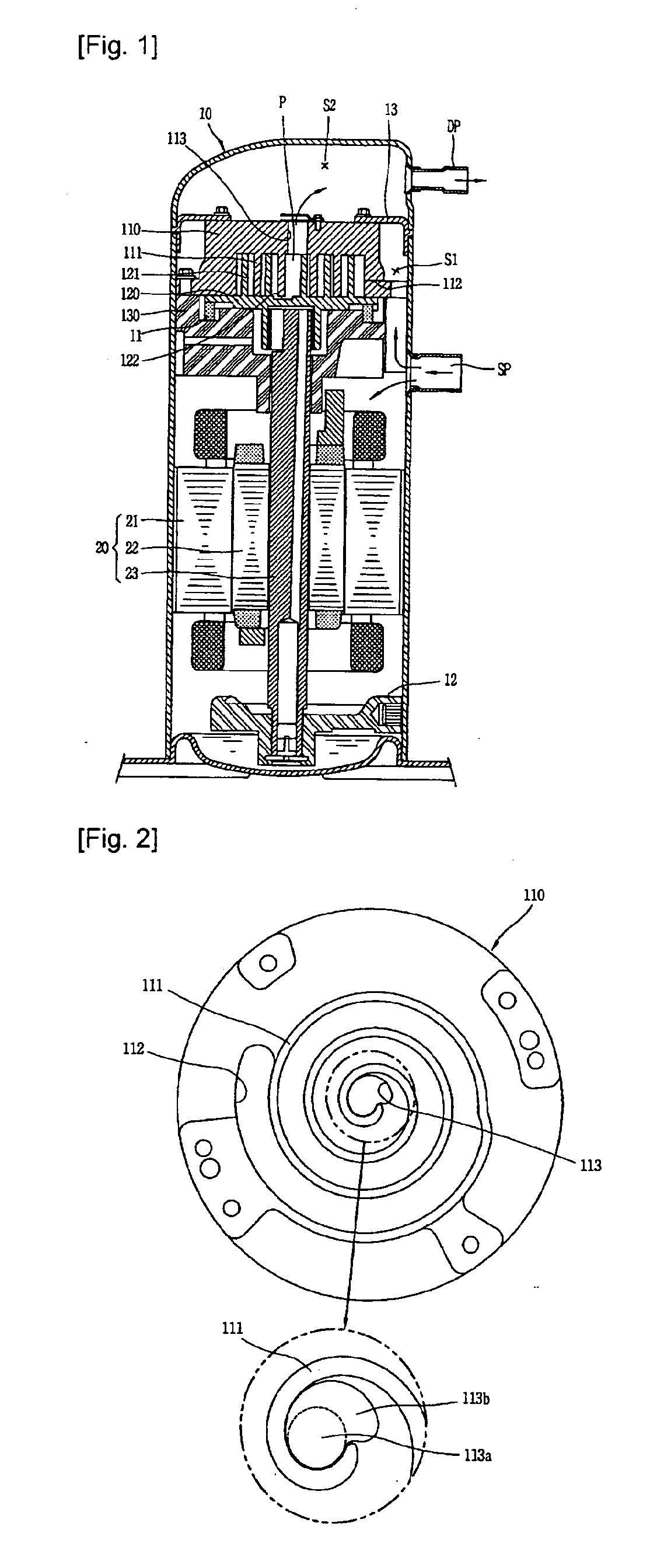

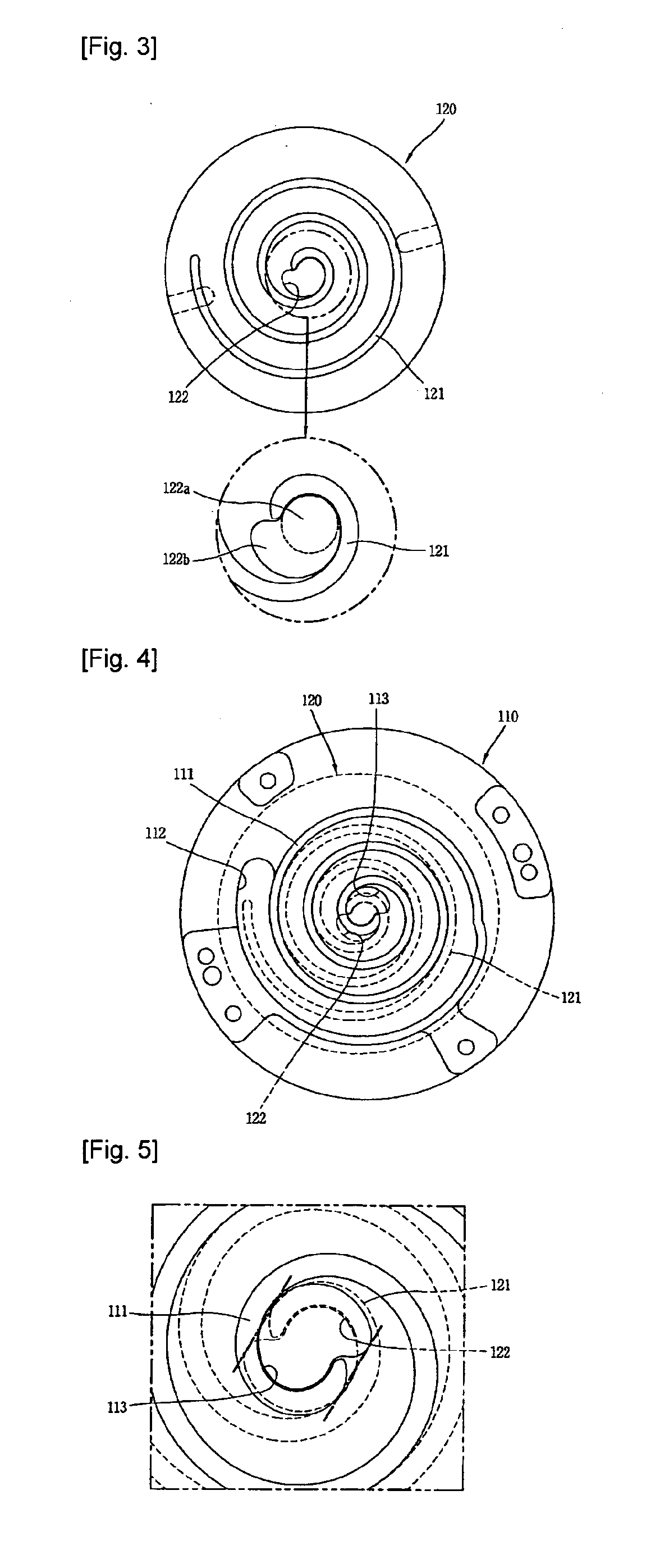

[0017]Hereafter, description will now be given in detail of one embodiment of a scroll compressor according to the present invention with accompanying drawings.

[0018]As shown in FIG. 1, the scroll compressor includes a casing 10, a driving motor 20 installed at an upper portion of the casing 10 and generating a rotational force and a compression unit 30 installed at an upper portion of the case 10 and compressing a refrigerant after receiving the rotational force generated from the driving motor 20.

[0019]The casing 10 has an inner space in a hermetic state. A suction pipe (SP) is communicated with a middle of a wall surface of the casing 10 so as to suck the refrigerant from a refrigeration cycle apparatus. And, a discharge pipe (DP) is communicated with an upper portion of the wall surface of the casing 10 so as to discharge the refrigerant having been compressed in the compression unit 30 to the refrigeration cycle apparatus. A main frame 11 and a sub frame 12 are respectively fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com