Valve drive of an internal combustion engine

a technology of internal combustion engine and valve drive, which is applied in the direction of valve arrangement, machines/engines, mechanical equipment, etc., can solve the problems of rapid conflict between the length of the cam piece and the installation space available for the piece, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

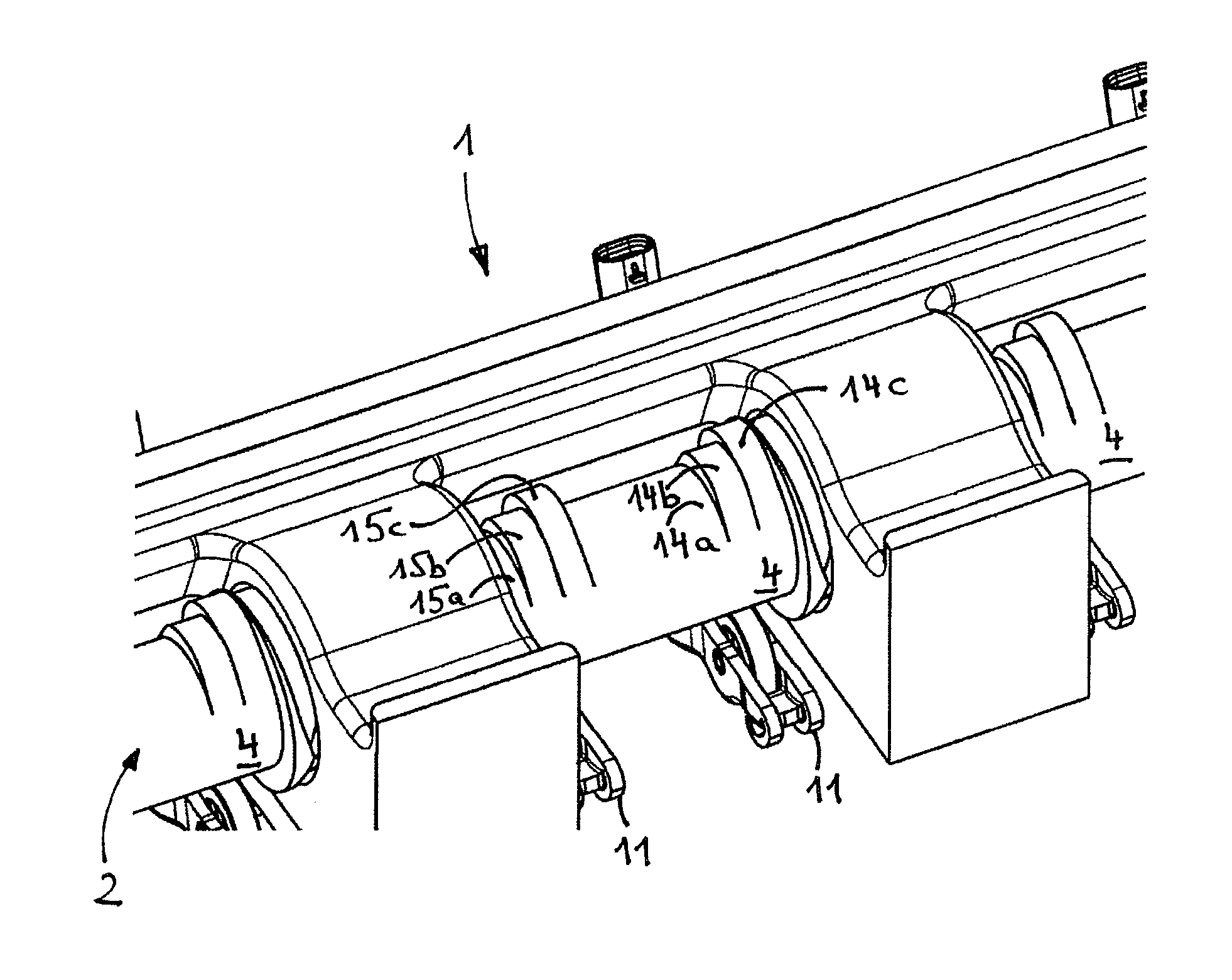

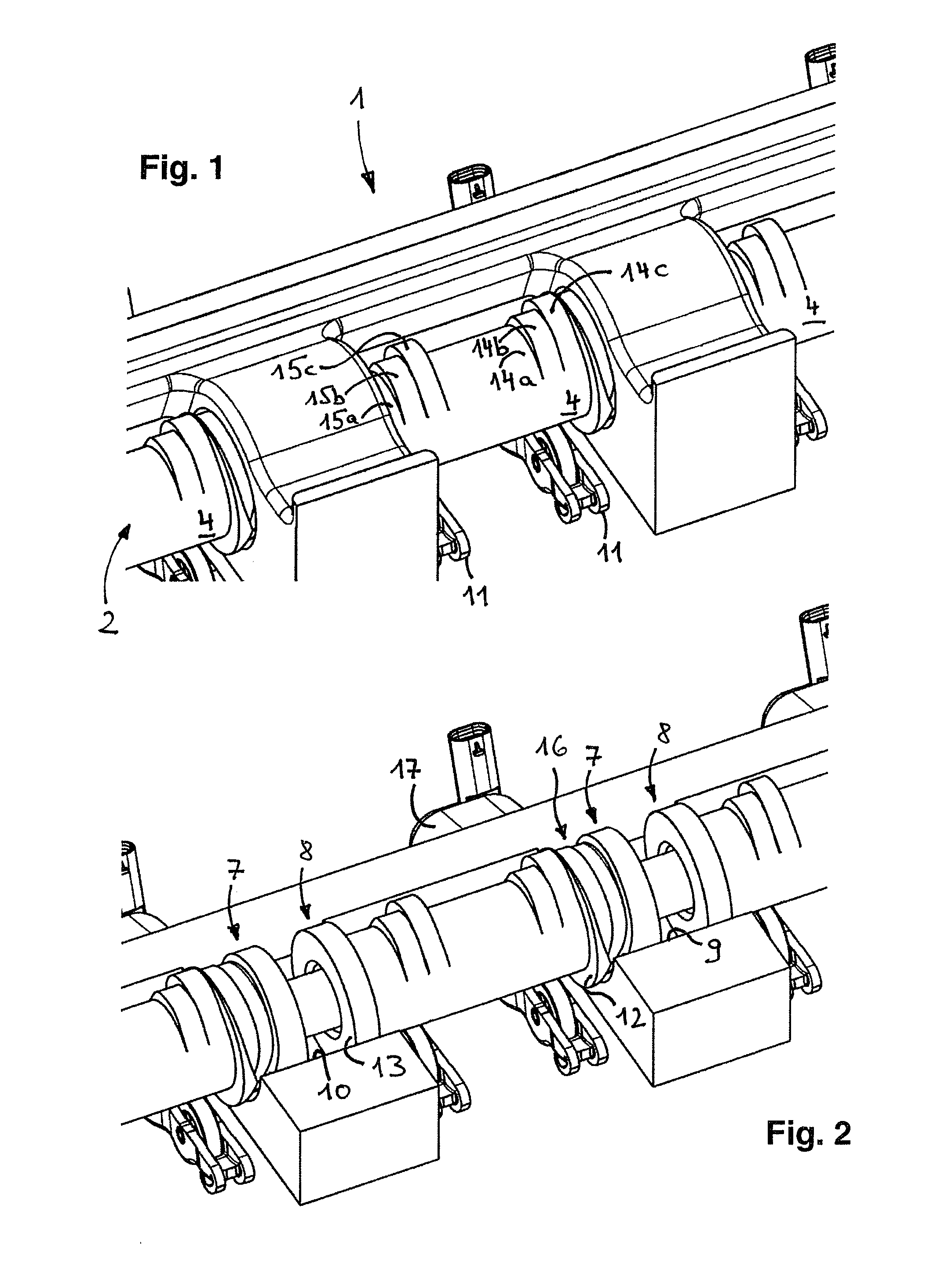

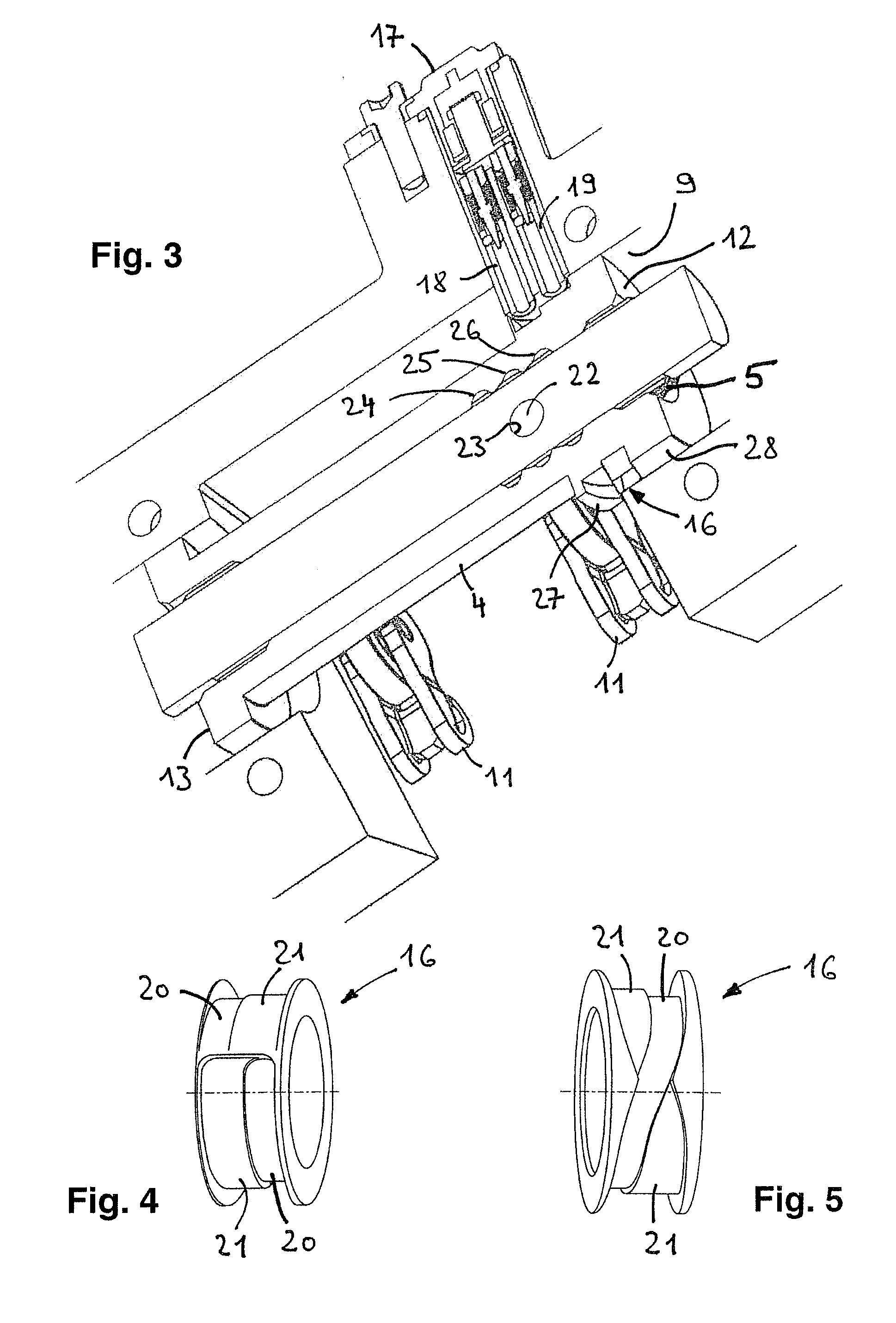

[0030]In FIGS. 1 to 3, a cutout section of a valve drive 1 of an internal combustion engine that is essential for understanding the invention is disclosed with stroke-variable gas-exchange valve activation and four-valve technology. A component that is central to the function of the valve drive 1 is a camshaft 2 that comprises a carrier shaft 3 and also cam pieces 4 that are arranged in a rotationally locked way on the carrier shaft and that can move between three axial positions—corresponding to the number of cylinders of the internal combustion engine. For the purpose of axial shifting, the carrier shaft 3 is provided with outer longitudinal teeth and each cam piece 4 is provided with corresponding inner longitudinal teeth. The teeth 5 and 6 can be seen in FIGS. 3 and 8. The intermediate spaces that can be seen between the axial end sections 7 and 8 allow the separate shifting of the cam pieces 4 in sync with the ignition sequence of the internal combustion engine into an adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com