Carbon nanotubes for the selective transfer of heat from electronics

a technology of carbon nanotubes and electronics, applied in the field of nanotube fabrics, can solve the problems of increasing the need for smaller and more potent heat transfer devices, high localized heating of integrated circuits, and the use of individual nanotubes for heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

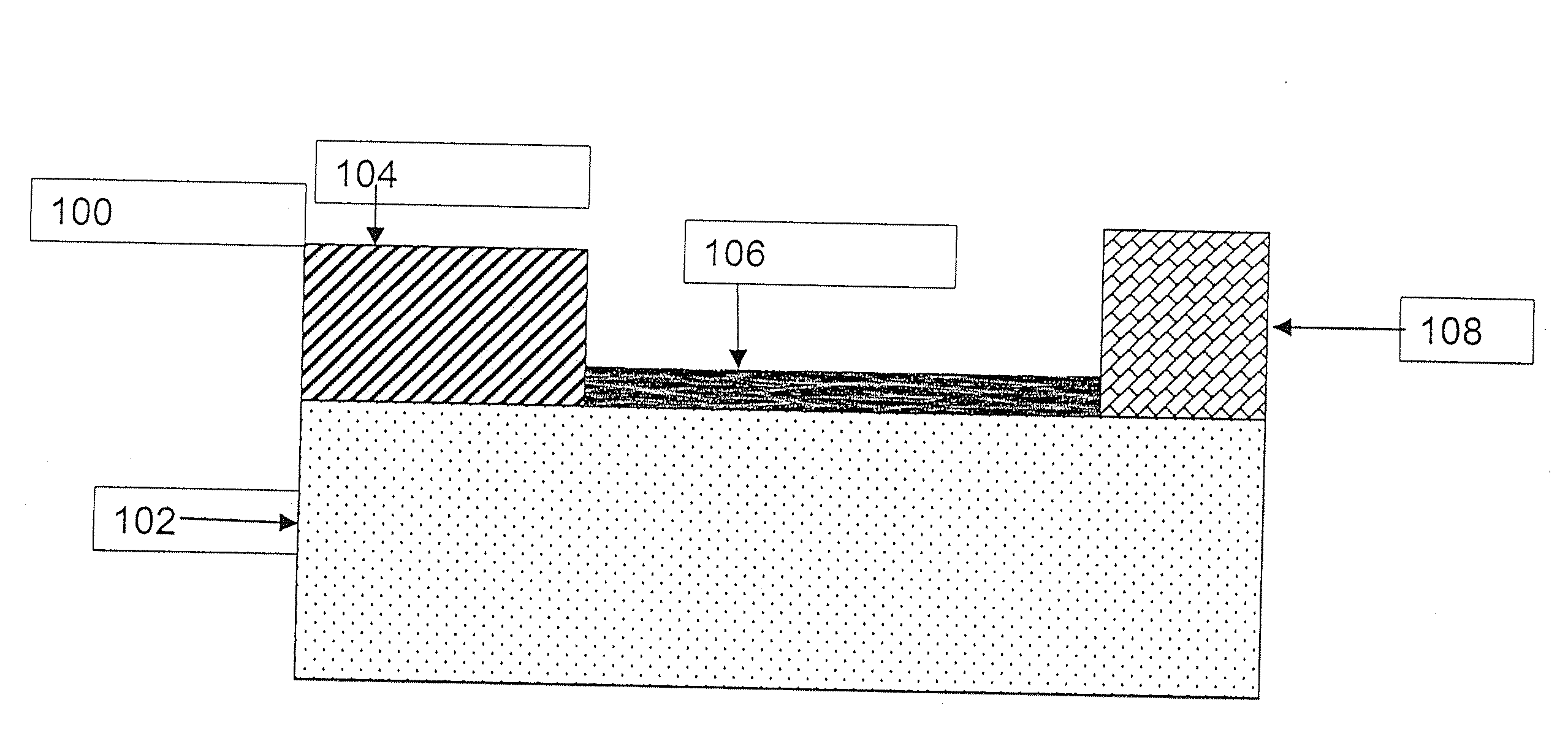

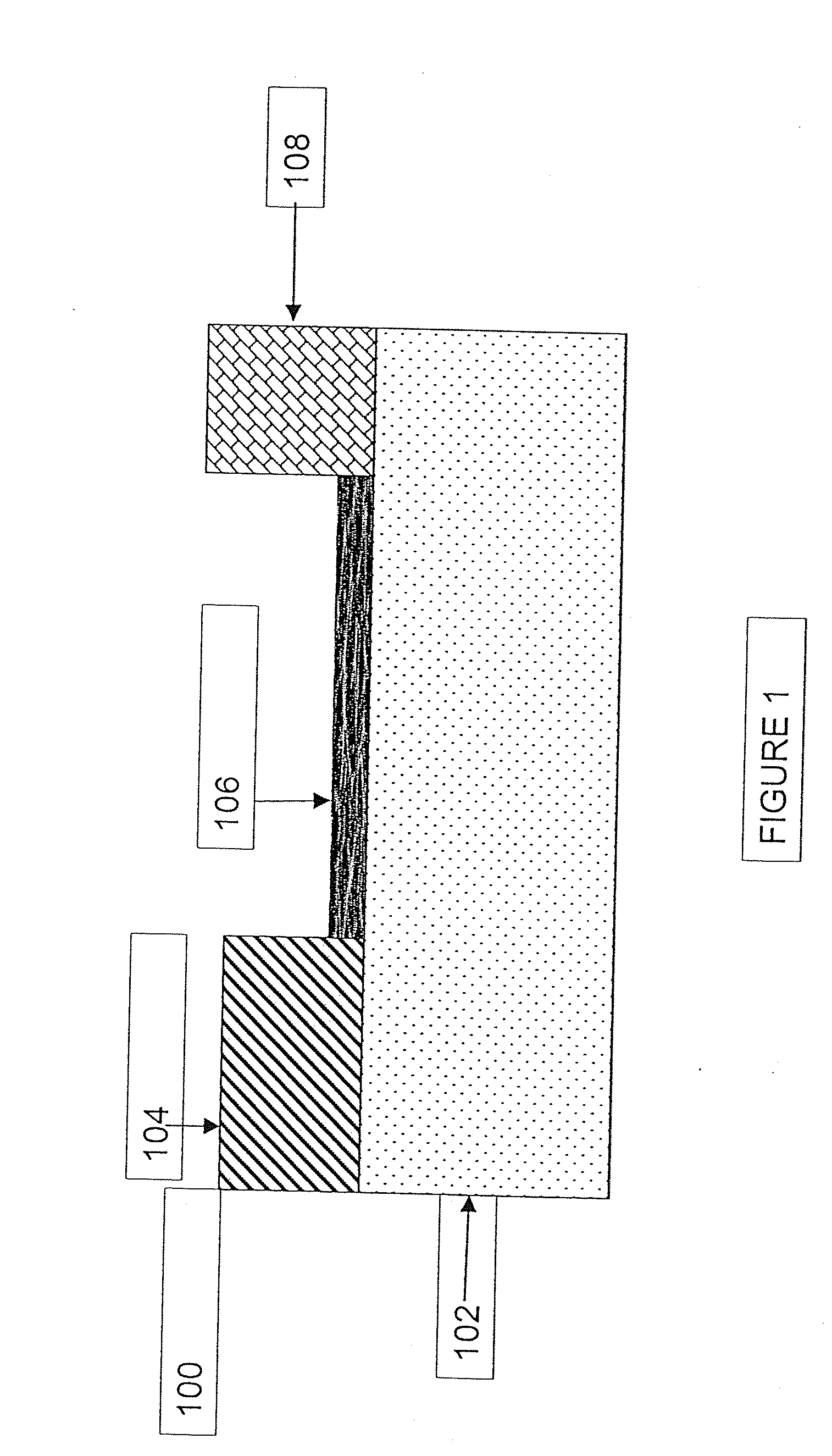

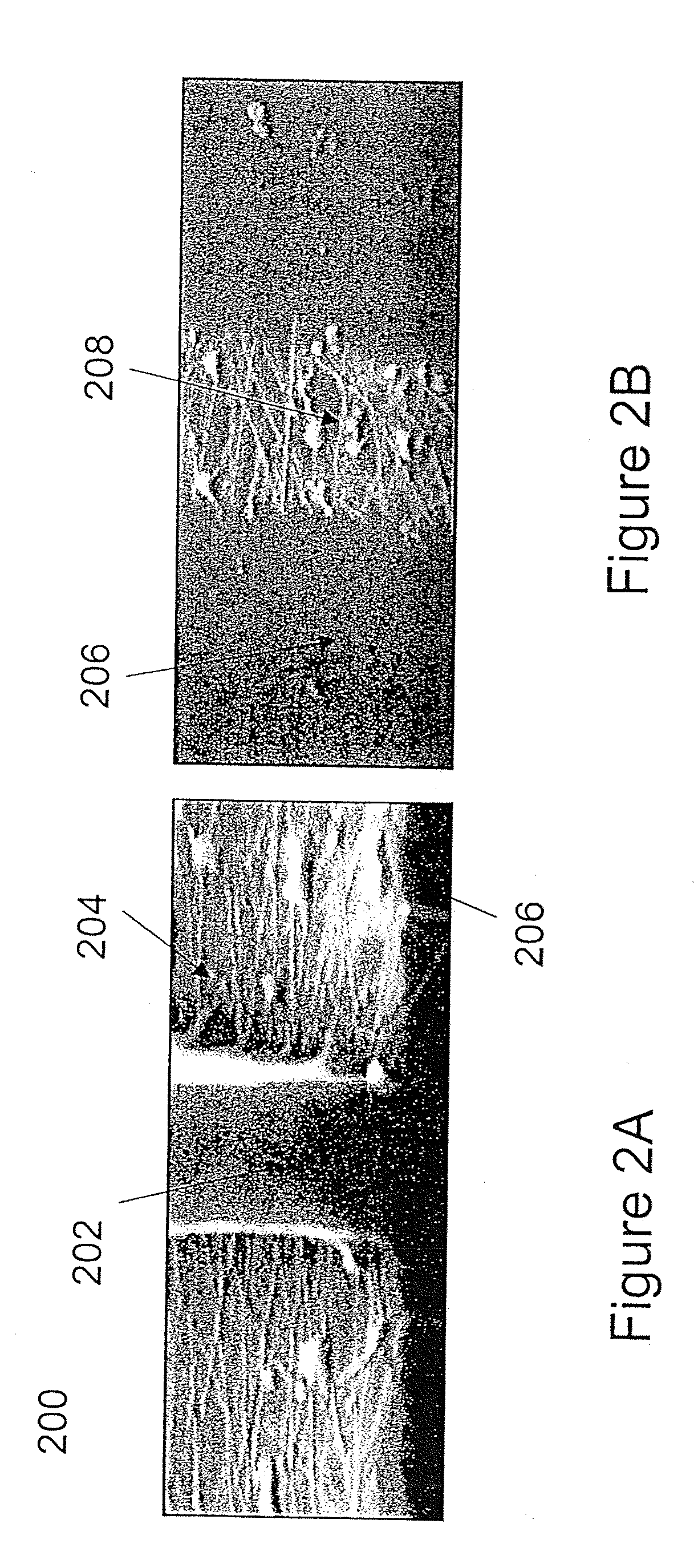

[0026]Non-woven fabrics of carbon nanotubes (CNTs) can help manage the problem of thermal “hot spots” and heat transfer in high power devices. CNT fabrics have superior thermal conductance relative to single nanotube as well as to conventional conductive materials such as metals, and therefore the CNT fabrics have a tremendous potential for providing extremely efficient heat transfer. CNTs exhibit a very high “axial” thermal conductivity. For a discrete multiwalled nanotube (MWNT), the thermal conductivity is expected to surpass 3000 W / m-k along the tube axis, while theoretical studies of single walled nanotubes (SWNTs) have shown that thermal conductivities of 6600 W / m-K are possible. CNT fabrics can be used as effective heat-sinks, which are able to remove large amounts of heat away from critical “hot spots”.

[0027]Preferred embodiments of this invention use CNT fabrics for the transfer of heat away from heat sensitive areas in an electronic circuit or from an entire electronic chi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com