Centrifugal impeller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Hereinafter, preferred embodiments of the invention are described in detail with reference to the accompanying drawings.

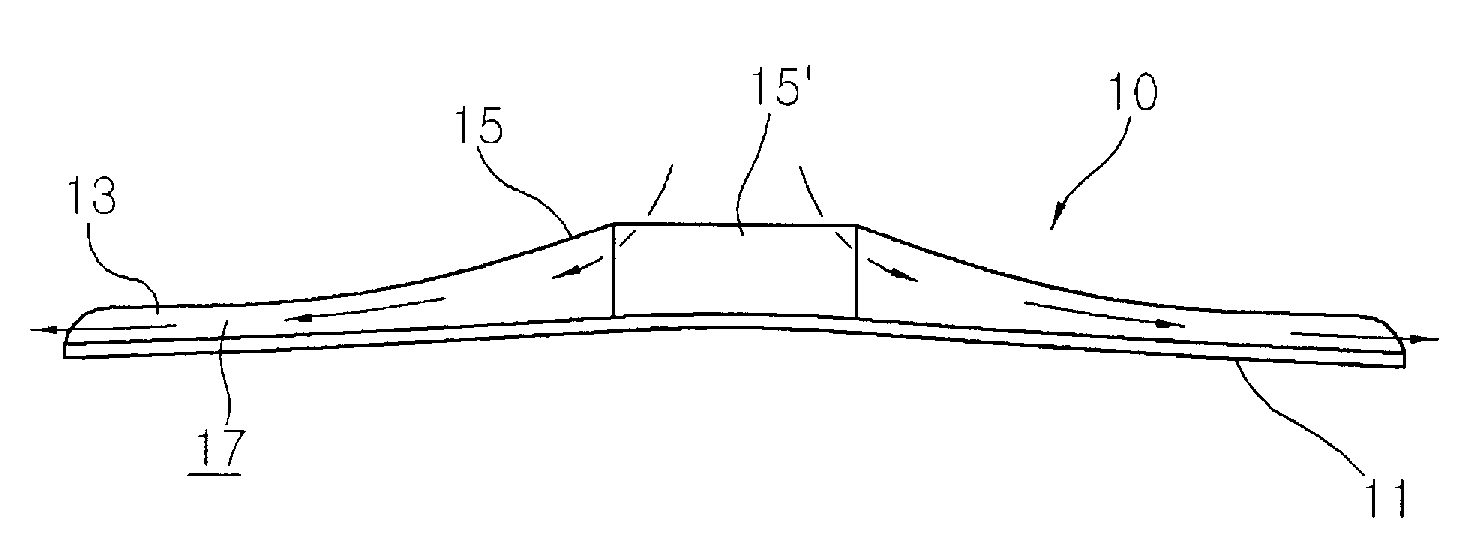

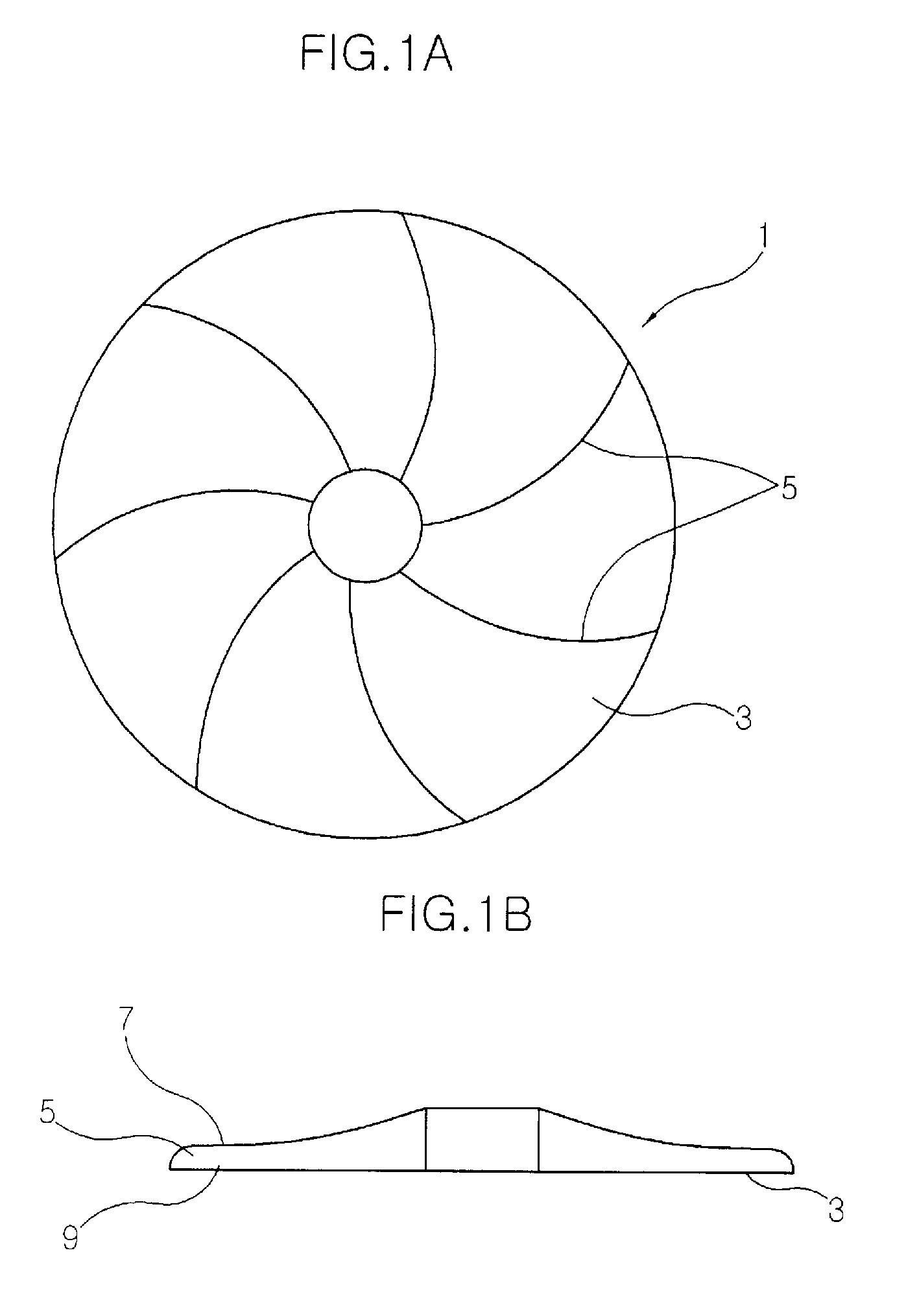

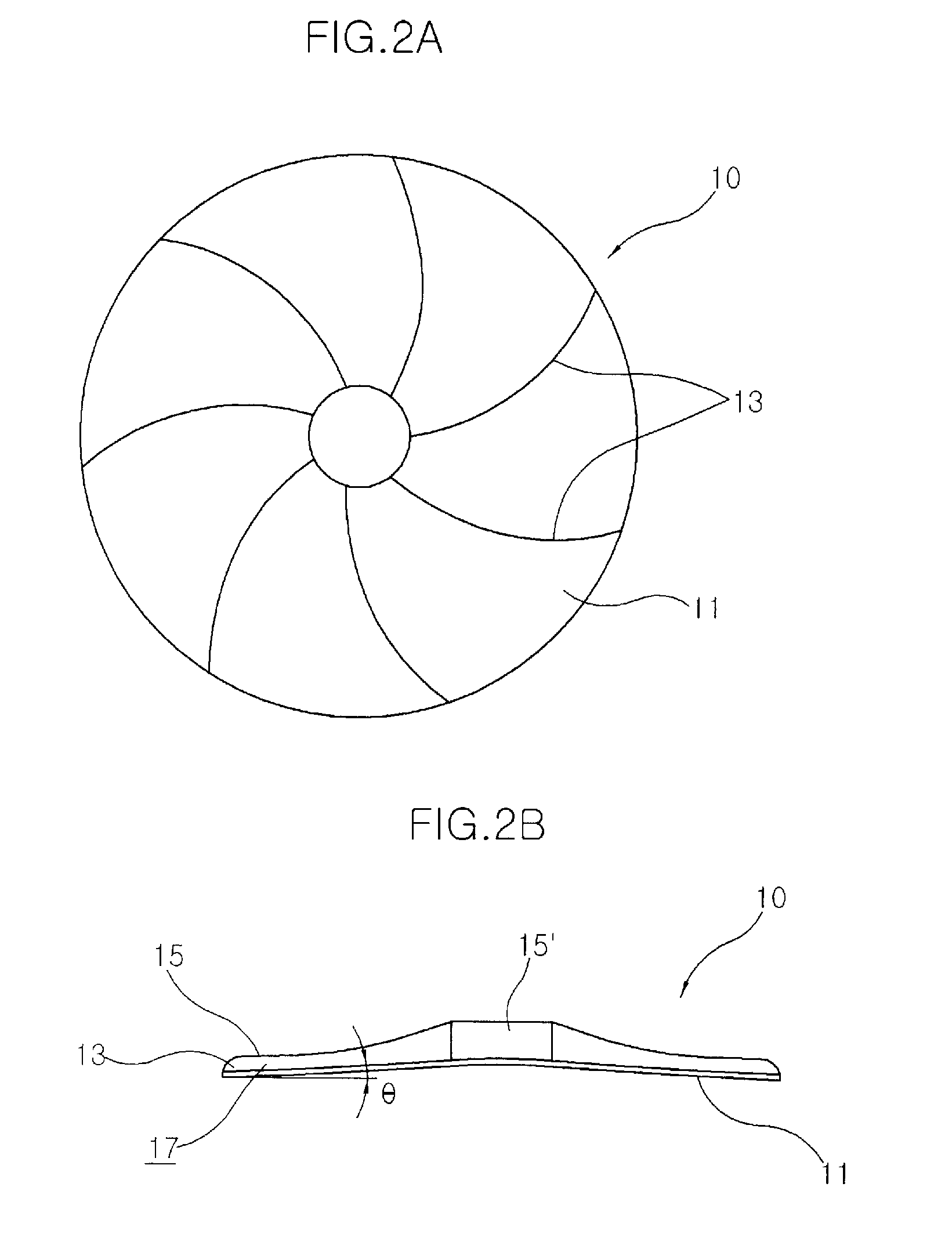

[0025]FIGS. 2A and 2B are a front view and a side view, respectively, showing a preferred embodiment of a centrifugal impeller according to the present invention, FIG. 3 is a view illustrating flow of fluid that flows through an enlarged channel according to the present invention, and FIG. 4 is a graph illustrating the relationship between the angle of a base plate and a coefficient of loss.

[0026]Referring to the figures a centrifugal impeller 10 includes a base plate 11 having a rotary shaft socket (not shown) at the center portion, blades 13 circumferentially arranged on the upper surface of the base plate 11, and a scroll casing 15 disposed at the fronts of the blades 13.

[0027]As shown in FIGS. 2A and 2B, the base plate 11 is a substantially circular plate, which forms the lower outer shape of the centrifugal impeller 10. The base plate 11 is sloped downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com