Heat exchanger having micro-channels

a heat exchanger and microchannel technology, applied in the direction of lighting and heating apparatus, stationary conduit assemblies, laminated elements, etc., can solve the problems of large amount of heat transfer, difficult to meet a spatial condition within the device for mounting the heat exchanger, and difficult to adapt the same, etc., to achieve high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

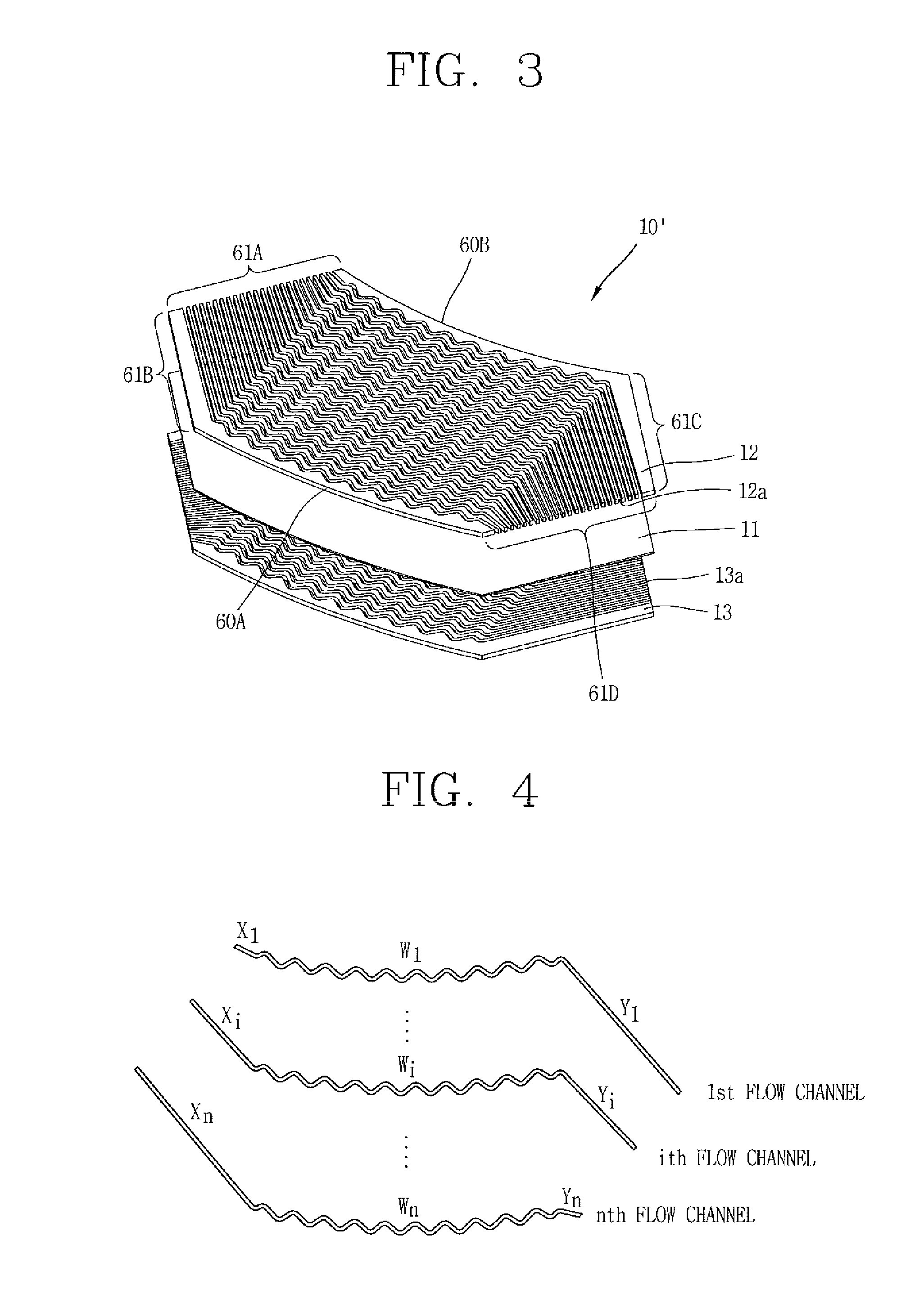

[0027]Description will now be given in detail of the present invention, with reference to the accompanying drawings.

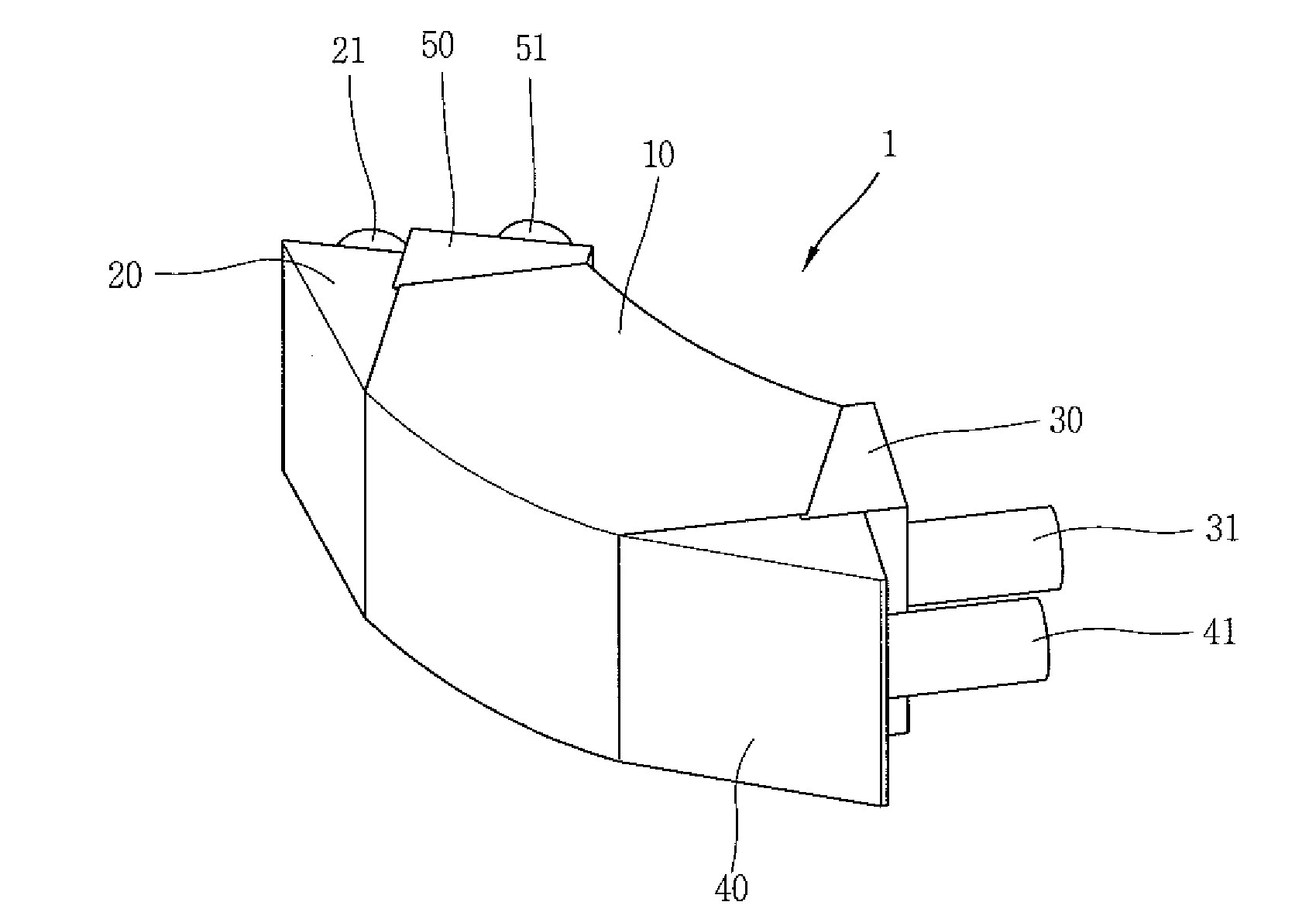

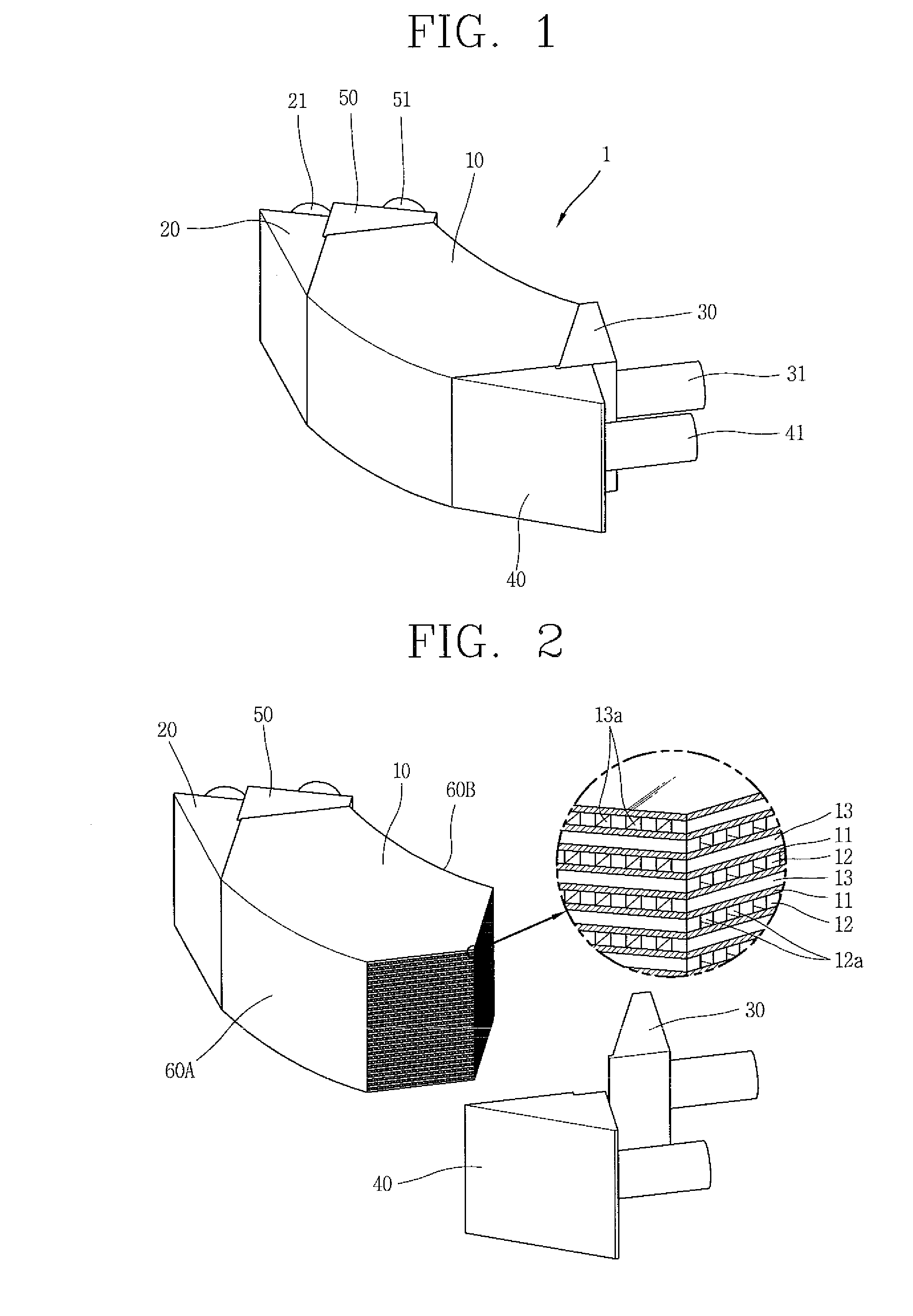

[0028]FIG. 1 is a perspective view showing one example of a micro-channel heat exchanger in accordance with the present invention. As shown in FIG. 1, a heat exchanger may include a heat exchanger body 10 having a curved shape, a high temperature fluid inlet body 20 and a low temperature fluid outlet body 50 detachably connected to one end portion of the heat exchanger body 10, and a low temperature fluid inlet body 40 and a high temperature fluid outlet body 30 attached onto another end portion of the heat exchanger body 10.

[0029]One side surface 60A of both side surfaces 60A and 60B (see FIG. 2), which define a width of the heat exchanger body 10 may have a first curvature profile, and another side surface 60B may have a second curvature profile in parallel to the first curvature profile. The first curvature profile and the second curvature profile may possibly be ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com