Electric power equipment, and electronic device and power supply element inspection equipment using same

a technology of electronic devices and inspection equipment, applied in the direction of electric devices, electrochemical generators, batteries, etc., can solve the problems of increasing the size of the electric power equipment, and achieve the effects of enhancing the safety of the electronic device to be used, reducing the size of the electric power equipment, and enhancing the safety of the inspection equipment of the power supply elemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first exemplary embodiment

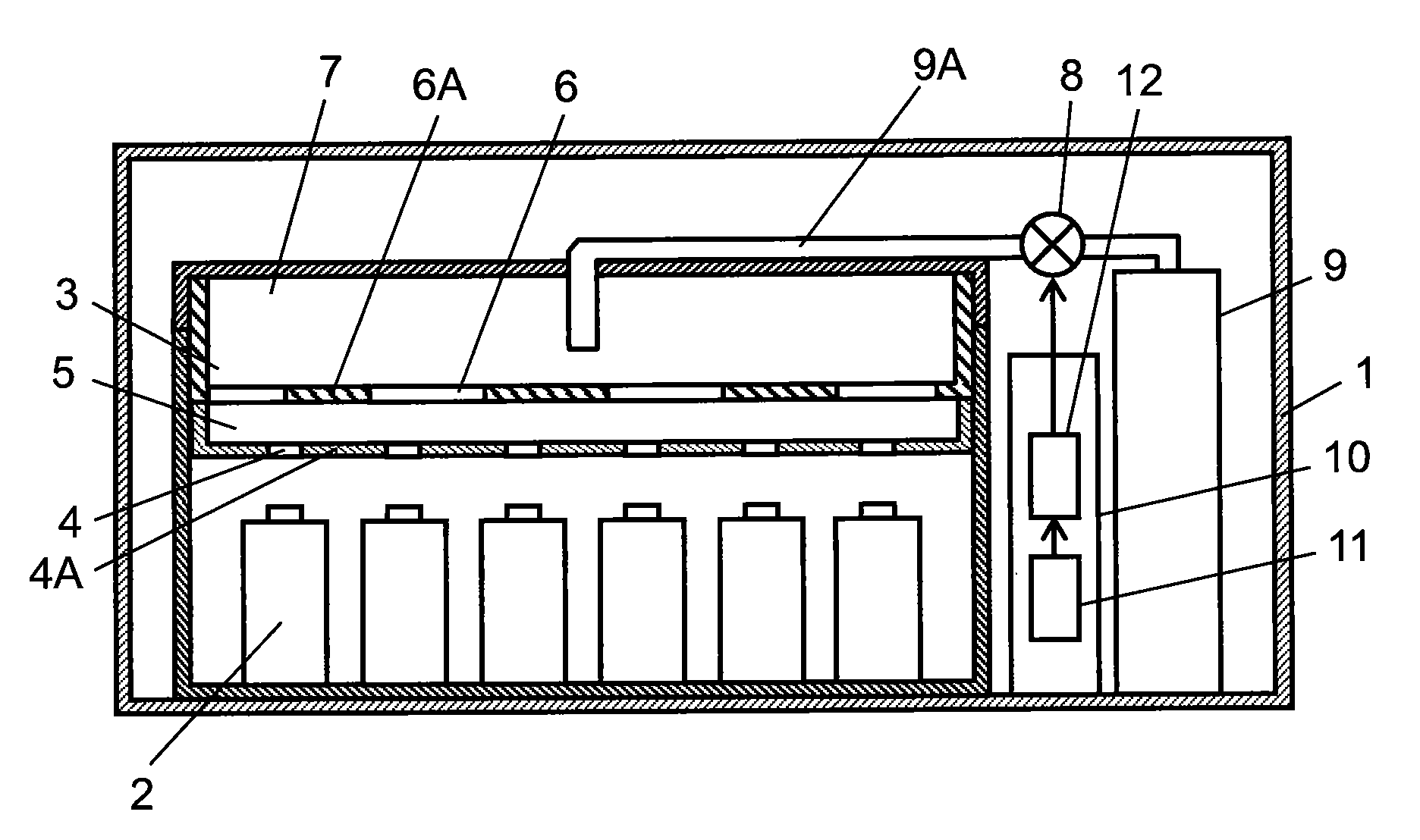

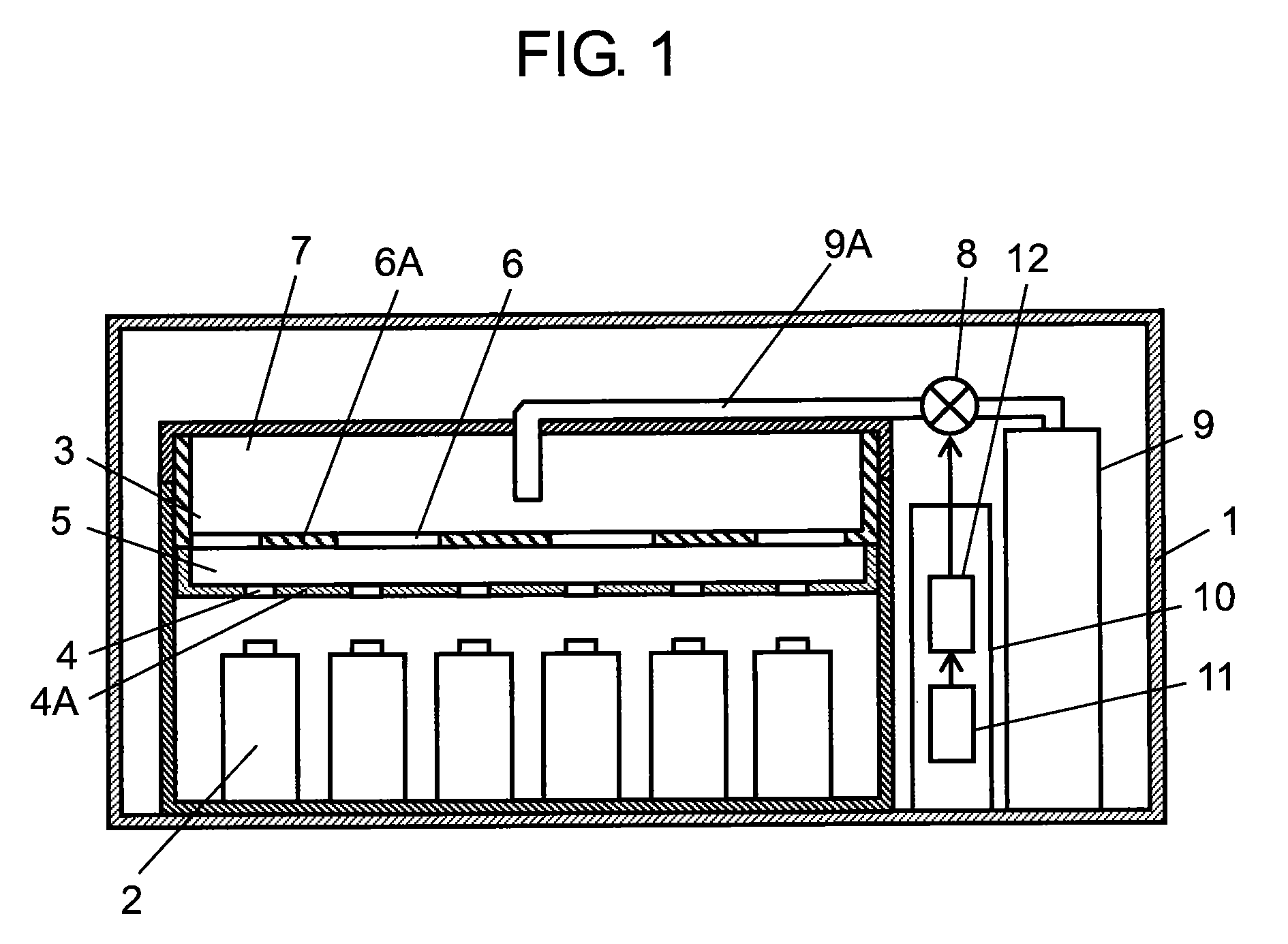

FIG. 1 is a sectional view of electric power equipment in accordance with a first exemplary embodiment of the present invention. As shown in FIG. 1, the electric power equipment includes main body case 1, power supply elements 2 accommodated in main body case 1, and fire-extinguishing agent discharge space 3 facing power supply elements 2.

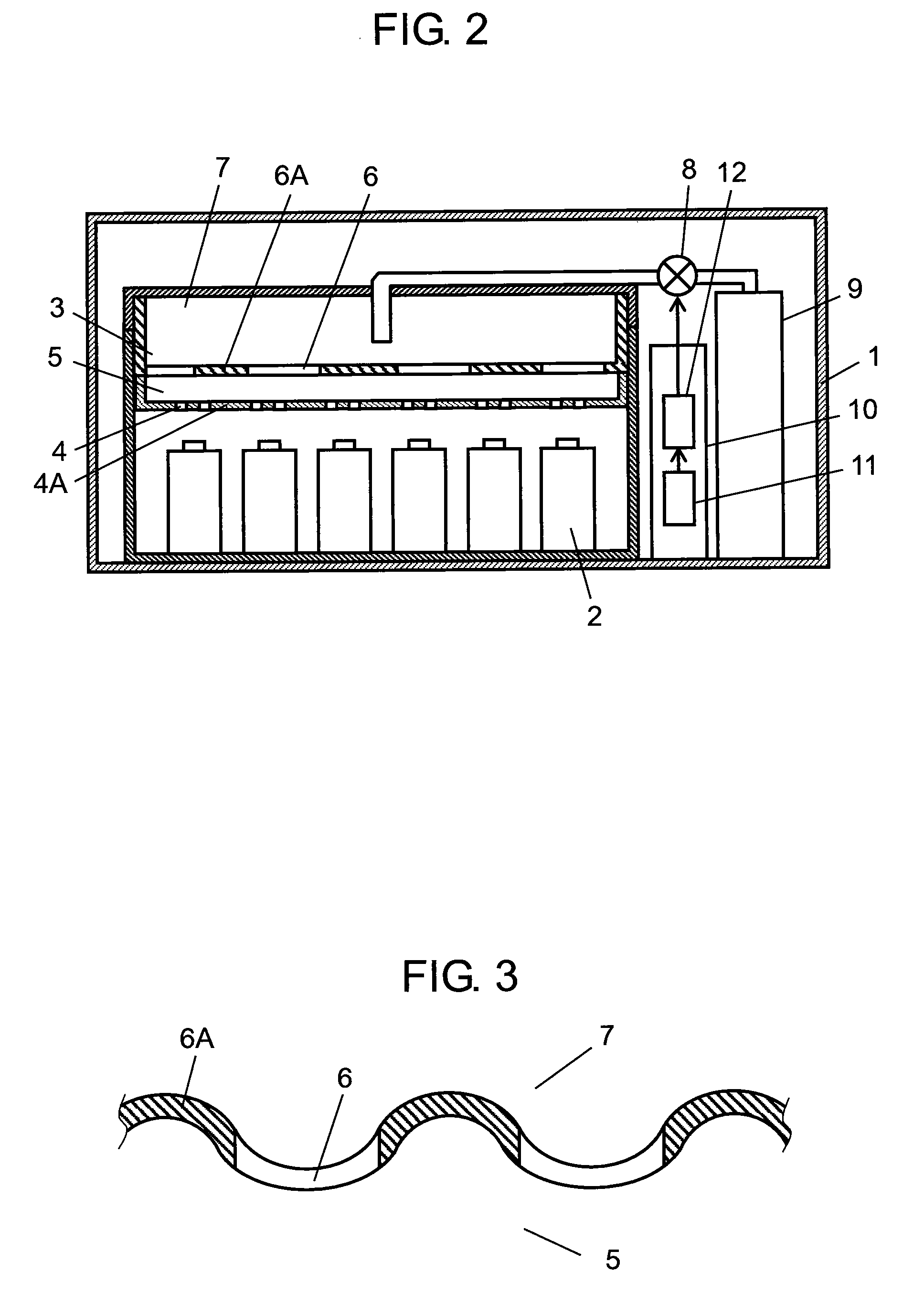

Furthermore, fire-extinguishing agent discharge space 3 includes fire-extinguishing agent spray space 5 having fire-extinguishing agent spray holes 4 for spraying a fire-extinguishing agent toward power supply elements 2, and fire-extinguishing agent supply space 7 coupled to fire-extinguishing agent spray space 5 via fire-extinguishing agent supply holes 6. Fire-extinguishing agent tank 9 is coupled to fire-extinguishing agent supply space 7 through piping 9A having shutoff valve 8.

Power supply elements 2 specifically are batteries or capacitors. This exemplary embodiment describes batteries as an example of power supply elements 2.

That is to say,...

second exemplary embodiment

Hereinafter, an electronic device in accordance with a second exemplary embodiment of the present invention is described in detail with reference to FIG. 4.

FIG. 4 is a view showing a configuration of an electronic device in accordance with the second exemplary embodiment of the present invention. As shown in FIG. 4, the electric power equipment in accordance with the first exemplary embodiment is used as a power source of an electronic device, for example, an electric vehicle. Note here that since the configuration and effect of the electric power equipment are the same as those of the first exemplary embodiment, the description thereof is omitted herein.

As shown in FIG. 4, the electronic device of this exemplary embodiment includes at least front wheels 14A coupled to axle shaft 13A, rear wheels 14B coupled to axle shaft 13B, shaft 15 coupling front wheels 14A and rear wheels 14B, power transmission unit 16 provided on front wheels 14A or rear wheels 14B, motor 17 for driving power...

third exemplary embodiment

Hereinafter, power supply element inspection equipment in accordance with a third exemplary embodiment of the present invention is described with reference to FIG. 5.

FIG. 5 is a view showing a configuration of power supply element inspection equipment in accordance with the third exemplary embodiment of the present invention. As shown in FIG. 5, the electric power equipment of the first exemplary embodiment is used as an inspection device of a power supply element and the like. Note here that since the configuration and effect of the electric power equipment are the same as those in the first exemplary embodiment, the description thereof is omitted.

As shown in FIG. 5, the power supply element inspection equipment in this exemplary embodiment includes at least the electric power equipment in accordance with the first exemplary embodiment and inspection system 20 for inspecting properties of the power supply elements in the electric power equipment.

Then, inspection system 20 includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| hydrophilic | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com