Structural absorbing material

A wave absorbing material and structural technology, applied in the field of wave absorbing materials, can solve the problems of application limitation, deterioration of wave absorbing performance, etc., and achieve the effects of reduced sensitivity, widened wave absorbing incident angle, and small electrical size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

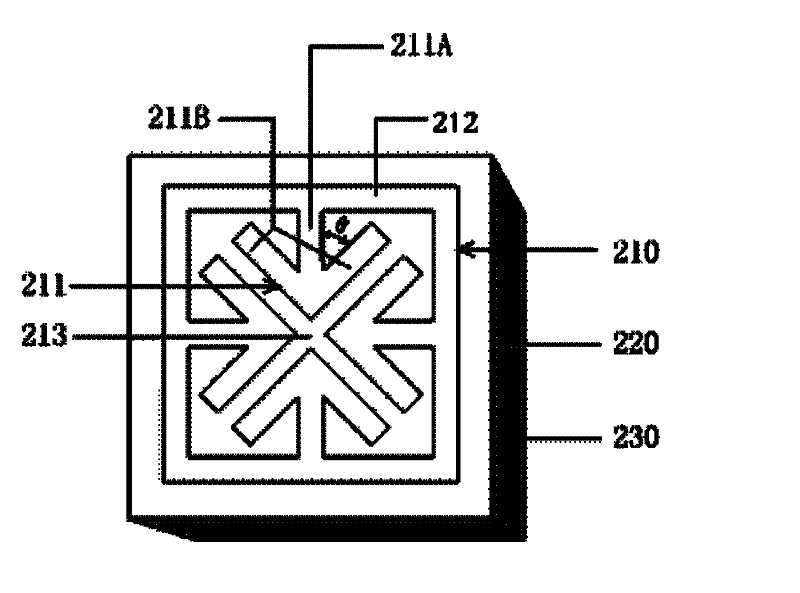

[0032] refer to figure 2 , the present invention selects double-sided copper-clad organic polymer dielectric substrate, and the substrate thickness is selected as λ / 68 according to the wavelength corresponding to the absorbing frequency band. One side of the substrate is etched with a metal pattern 210 , and the other side is not etched, which serves as an all-metal base plate 230 . The metal pattern 210 is composed of 4 metal wire arrows 211 pointing to the center and a regular quadrilateral metal wire frame 212. Two short lines 211B at the top of the 4 metal wire arrows 211 pointing to the center form a symmetrical cross structure. Glyph slit 213, the tail end of each metal wire arrow 211 is connected with regular quadrilateral metal wire frame 212, wherein the perimeter of regular quadrilateral metal wire frame 212 is 80λ / 100, two short lines 211B at the top of metal arrow 211, middle rod 211A and The line width of the metal wire frame 212 is λ / 120, the width of the cross...

Embodiment 2

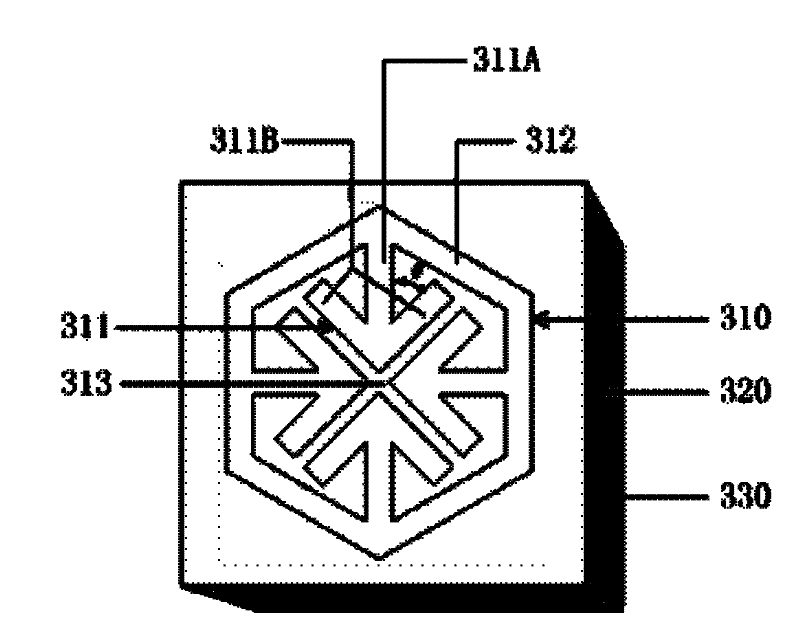

[0034] refer to image 3 , the present invention selects an inorganic ceramic dielectric substrate coated with copper on both sides, and the thickness of the substrate is selected as λ / 48 according to the wavelength corresponding to the absorbing frequency band. One side of the substrate is etched with a metal pattern 310 , and the other side is not etched, serving as a full metal base plate 330 . The metal pattern 310 is composed of 4 metal wire arrows 311 pointing to the center and a regular hexagonal metal wire frame 312. Two short lines 311B at the top of the 4 metal wire arrows 311 pointing to the center form a symmetrical cross structure. A cross-shaped gap 313, the tail end of each metal wire arrow 311 is connected to the regular hexagonal metal wire frame 312, wherein the perimeter of the regular hexagonal metal wire frame 312 is 82λ / 100, two short lines 311B at the top of the metal arrow 311, The line widths of the middle rod 311A and the metal wire frame 312 are b...

Embodiment 3

[0036] refer to Figure 4 , the present invention selects double-sided copper-clad organic polymer dielectric substrates, and the thickness of the substrate is selected as λ / 55 according to the wavelength corresponding to the absorbing frequency band. One side of the substrate is etched with a metal pattern 410 , and the other side is not etched, which serves as a full metal base plate 430 . The metal pattern 410 is composed of 4 metal wire arrows 411 pointing to the center and a regular octagonal metal wire frame 412 with a perimeter of 88λ / 100, and the two short lines at the top of the 4 metal wire arrows 411 pointing to the center have a length of 56λ / 500 411B forms a symmetrical cross structure, in the middle of which there is a cross-shaped slit 413 with a width of λ / 140, and the angle between the two short lines 411B at the top of each metal wire arrow 411 and the rod 411A is θ=45°, and The tail end of each metal wire arrow 411 is connected to the regular octagonal meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com