Deployment System

a deployment system and coiled tubing technology, applied in the direction of sealing/packing, drilling pipes, wellbore/well accessories, etc., can solve the problems of occupying valuable space, requiring substantial reels of coiled tubing, and being extremely difficult to accommodate, so as to reduce the time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

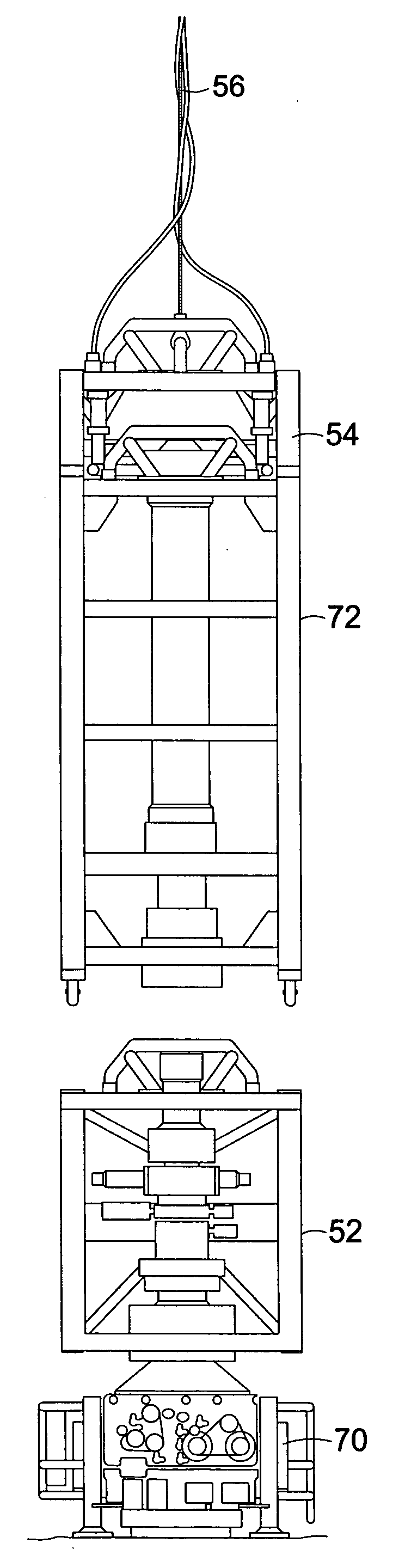

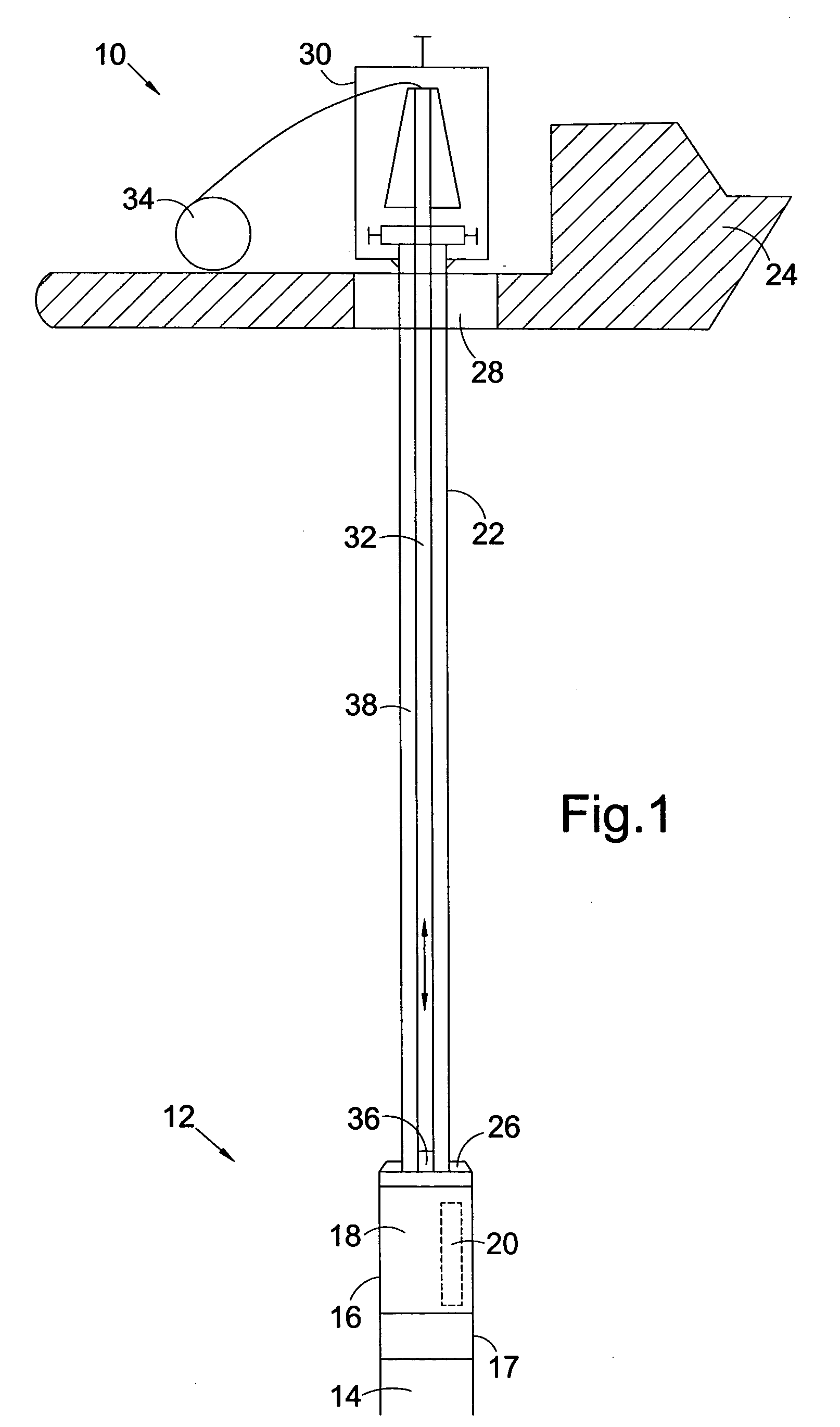

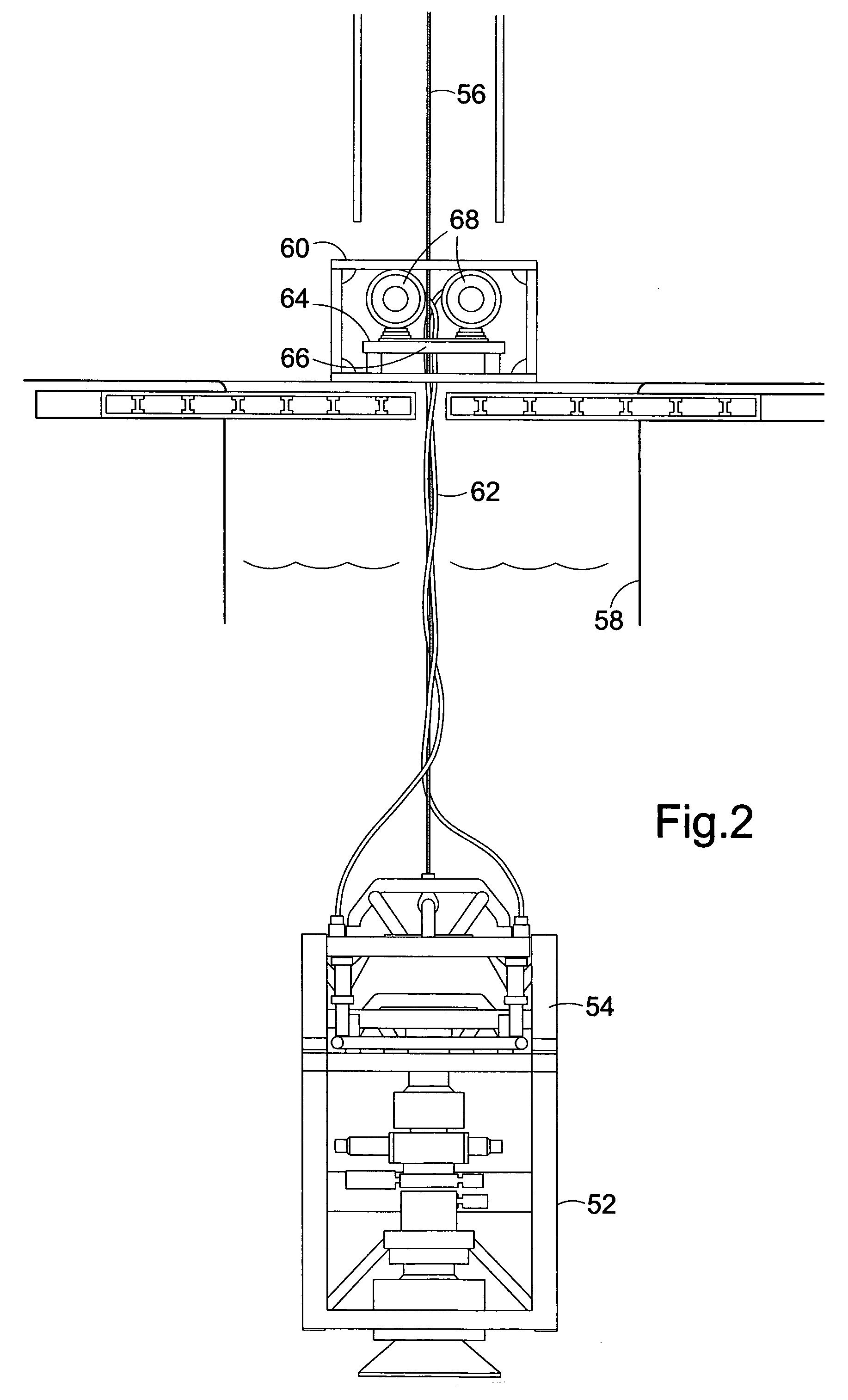

[0125]Referring to the FIG. 1, a tool deployment system according to an embodiment of an aspect of the present invention is shown diagrammatically. The tool deployment system, generally identified by reference numeral 10, includes a subsea assembly 12 mounted on an existing subsea wellhead 14. The subsea assembly 12 comprises a tool storage package 16 which defines a tool storage chamber 18 containing a plurality of downhole tools 20 (only one shown for clarity). The tool storage chamber 18 may contain intervention tools, drilling tools, logging tools or the like, or any suitable combination of tools selected from the art.

[0126]The system 10 further comprises a first tubular member 22 formed of a length of coiled tubing which extends from a surface vessel 24 and is secured at a lower end thereof to an upper portion of the tool storage package 16 via a latching mechanism 26. In one example, the coiled tubing used to define the first tubular member may describe an outer diameter of ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com