Axial flow fan for external rotor

a technology of axial flow fan and external rotor, which is applied in the direction of liquid fuel engine, vessel construction, marine propulsion, etc., can solve the problems of low production efficiency, high production cost, and inability to install this axial flow fan reliably, and achieves high production efficiency, simple assembly, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

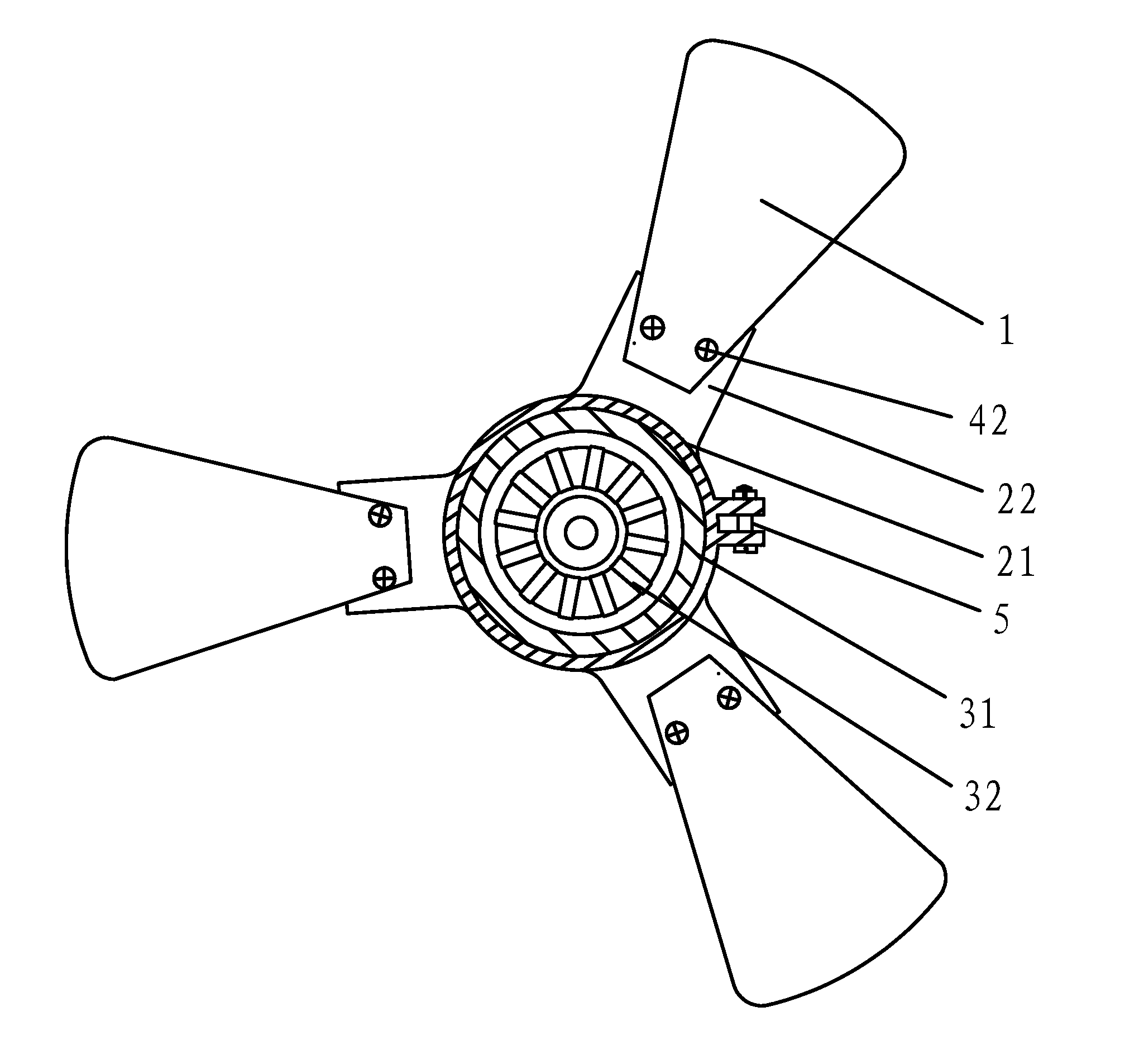

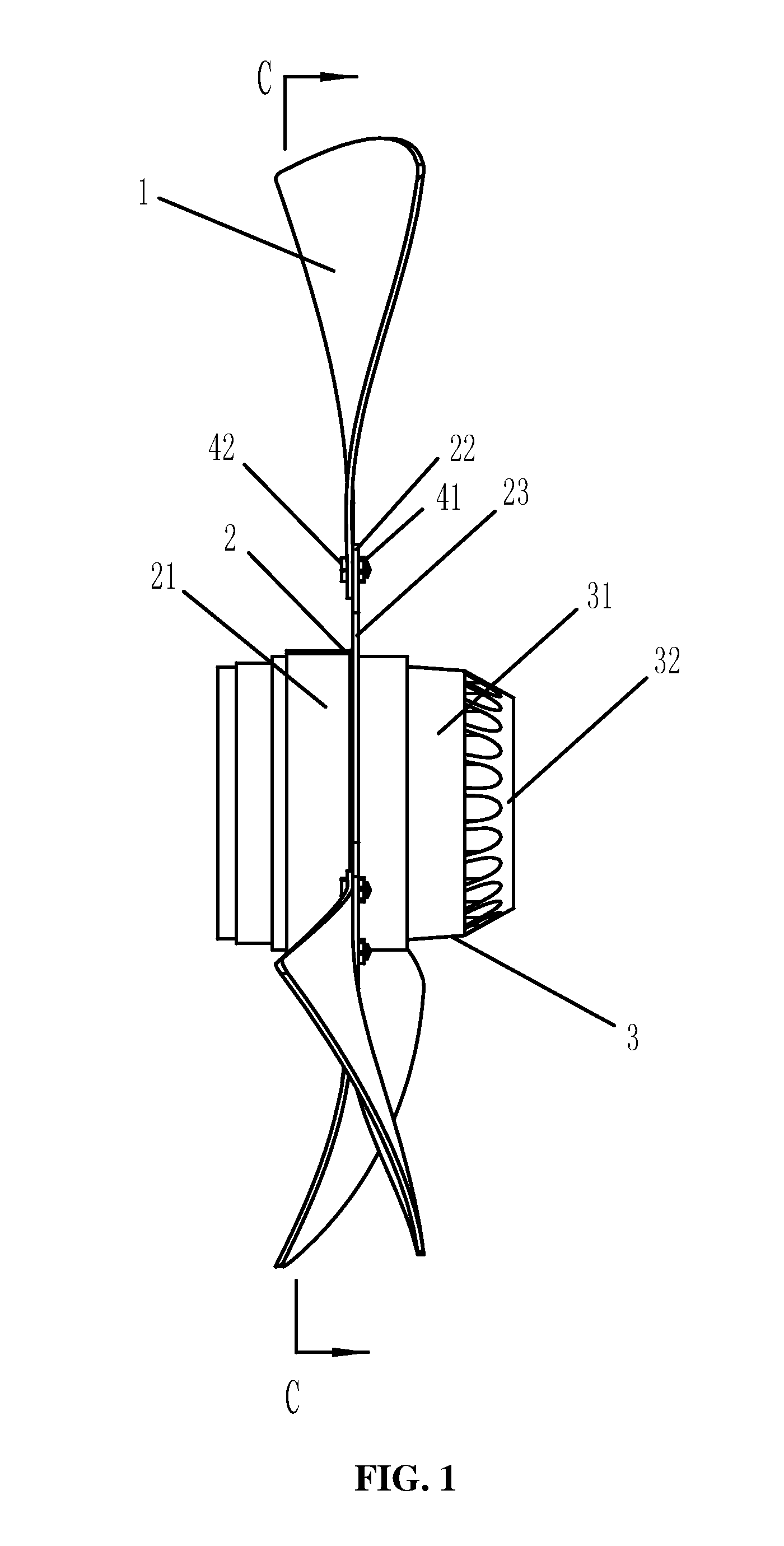

[0033]As shown in FIGS. 1 and 2, an axial flow fan for an external rotor of the invention comprises an axial flow blade 1, a support 2 comprising an annular cylinder 21 and multiple installation pins 22, an external rotor motor 3 comprising an external rotor 31 and an inner stator 32, and an external convex ring 23.

[0034]The installation pins 22 are extended from the outside of the annular cylinder 21.

[0035]The axial flow blade 1 is disposed on the installation pin 22.

[0036]The annular cylinder 21 is fit on the external rotor 31 of the external rotor motor 3, and is integrally formed.

[0037]The external convex ring 23 is disposed between the annular cylinder 21 and the installation pin 22, and operates to increase radial dimension and to improve structural strength.

[0038]Inner wall of the annular cylinder 21 is interference-fit with outer wall of the external rotor 31.

[0039]A screw hole is disposed on the installation pin 22, and the axial flow blade 1 is disposed on the installation...

second embodiment

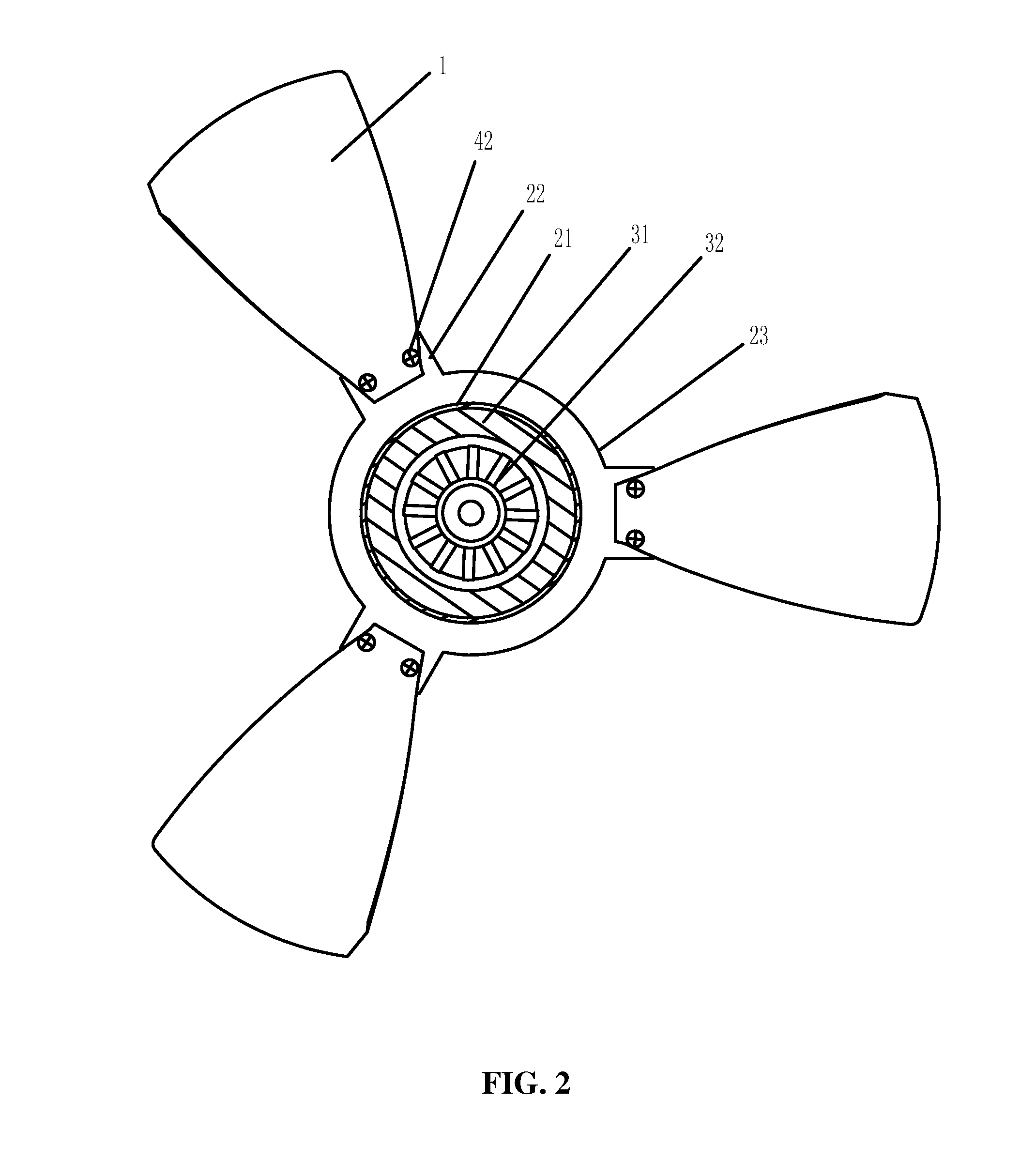

[0041]As shown in FIGS. 3 and 4, an axial flow fan for an external rotor of the invention comprises an axial flow blade 1, a support 2 comprising an annular cylinder 21 and multiple installation pins 22, and an external rotor motor 3 comprising an external rotor 31 and an inner stator 32.

[0042]The installation pins 22 are extended from the outside of the annular cylinder 21.

[0043]The axial flow blade 1 is disposed on the installation pin 22.

[0044]The annular cylinder 21 is fit on the external rotor 31 of the external rotor motor 3, and is formed by an annular body with an opening via a fastening device 5 or via welding.

[0045]Inner wall of the annular cylinder 21 is interference-fit with outer wall of the external rotor 31.

[0046]A screw hole is disposed on the installation pin 22, and the axial flow blade 1 is disposed on the installation pin 22 via nuts 42 and bolts 41. Alternatively, a through hole is disposed on the installation pin 22, and the axial flow blade 1 is disposed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com