Cosmetic Applicator with Disparate Material Application Zones and Backwipe Return

a cosmetic applicator and material technology, applied in the field of cosmetic applicators, can solve the problems of storing and transporting a plurality of cosmetic applicators, affecting the adaptability of cosmetic applicators to different materials and application goals, and requiring multiple cosmetic applicators to achieve varied application goals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]It will be appreciated that the cosmetic applicator with disparate material application zones described herein can pursue widely varied embodiments. However, to ensure that one skilled in the art will be able to understand and, in appropriate cases, practice the present invention, certain preferred embodiments of the broader invention revealed herein are described below and shown in the accompanying drawing figures. Before any particular embodiment of the invention is explained in detail, it must be made clear that the following details of construction, descriptions of geometry, and illustrations of inventive concepts are mere examples of the many possible manifestations of the invention.

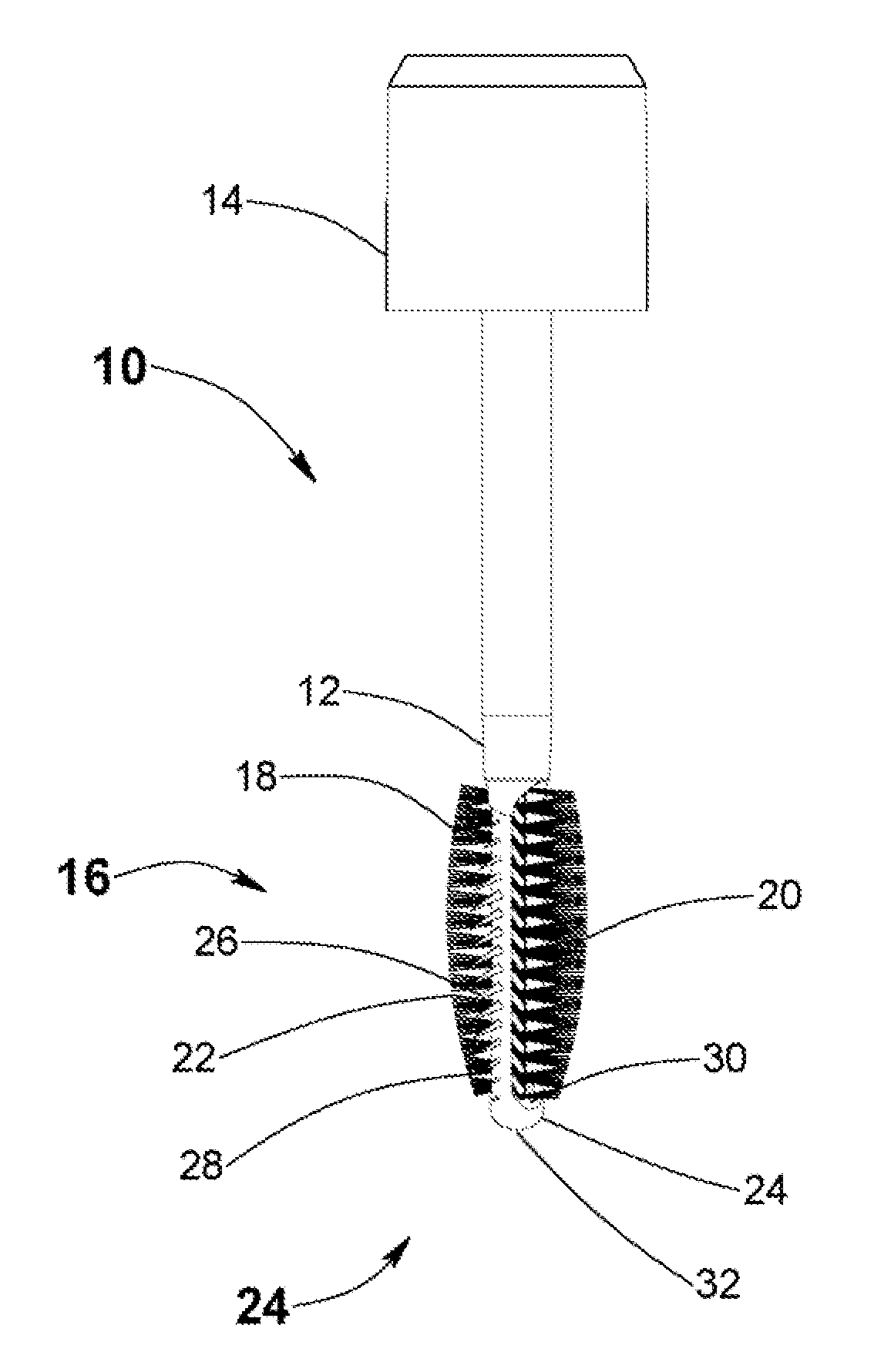

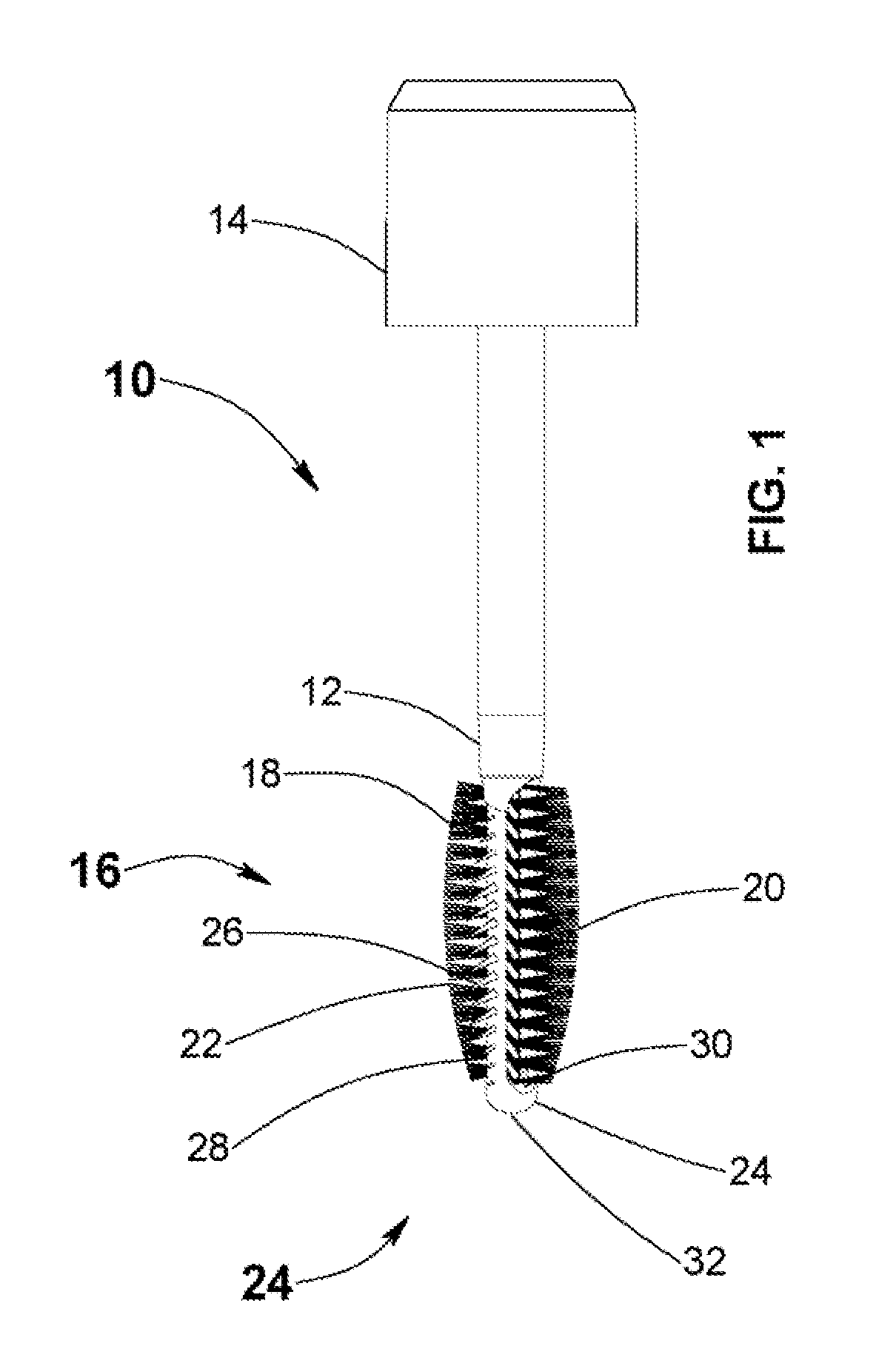

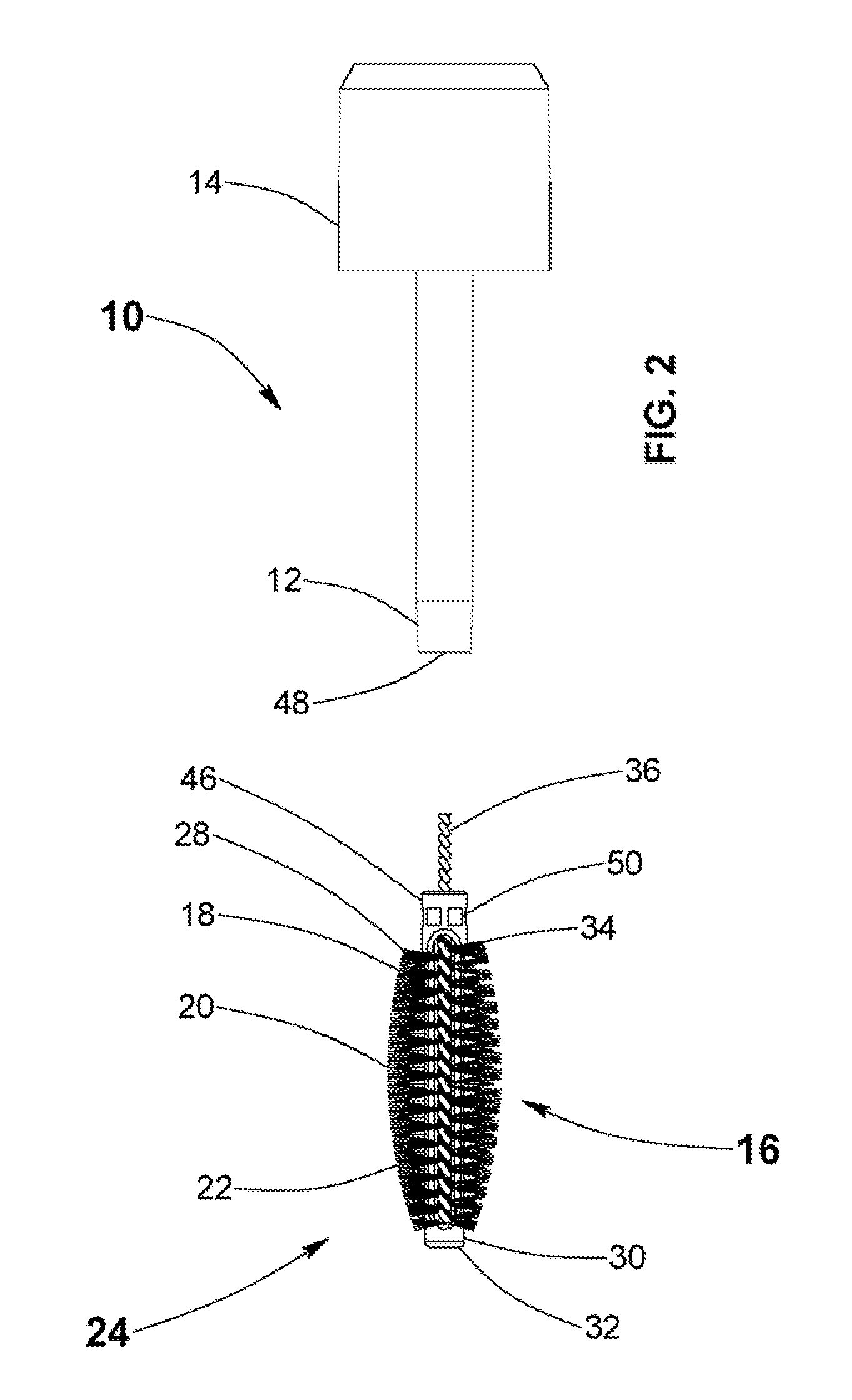

[0043]A manifestation of the present invention for a cosmetic applicator with disparate material application zones is indicated generally at 10 in FIG. 1. There, the cosmetic applicator 10 has an application rod 12 with a proximal end and a distal end. A cap 14, which also acts as a handle dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com