Water barrier for footwear

a water barrier and footwear technology, applied in the field of footwear, can solve the problems of saturating the footwear affecting the comfort of wearing, etc., and achieve the effects of facilitating air exchange, reducing friction, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

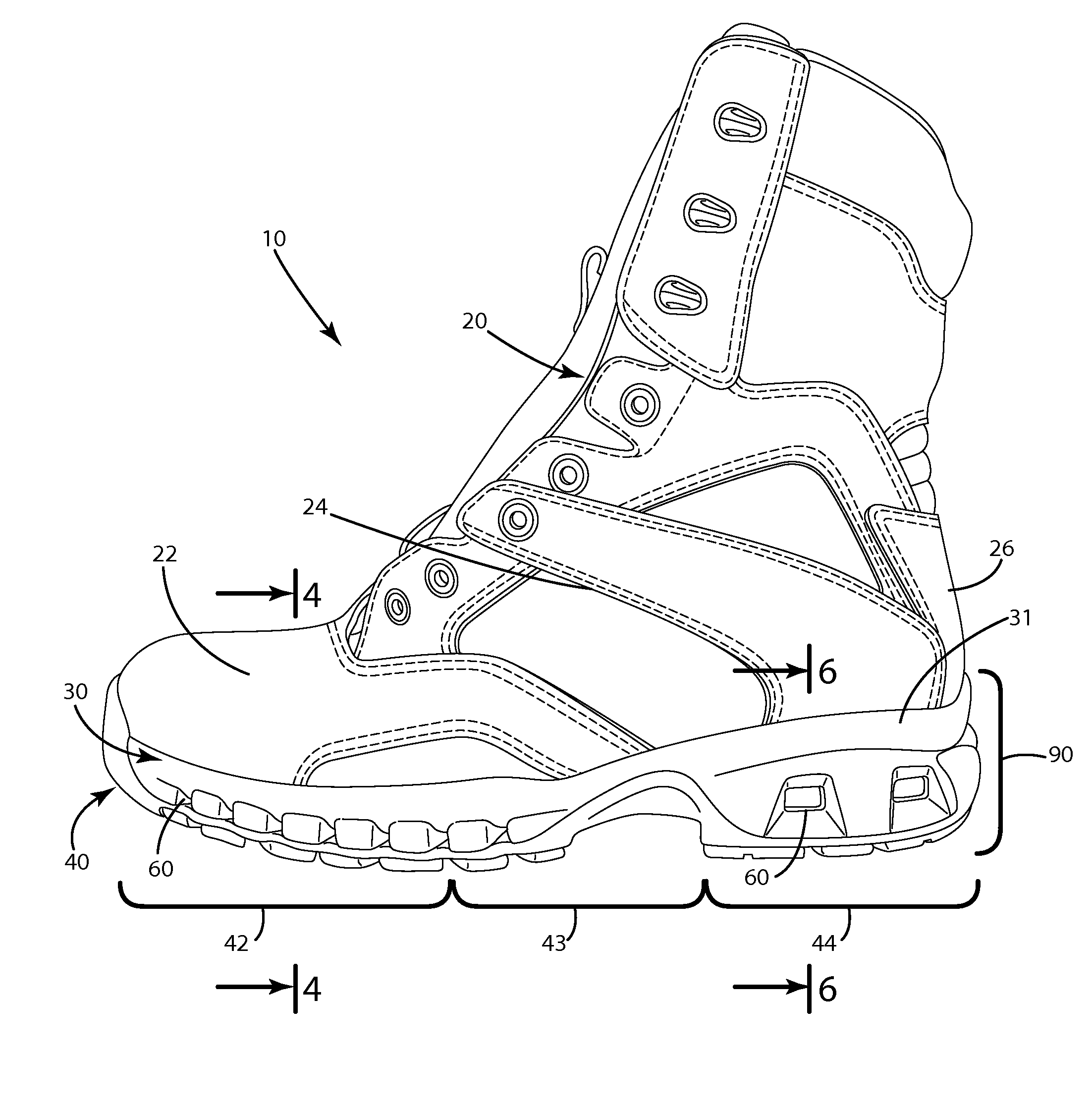

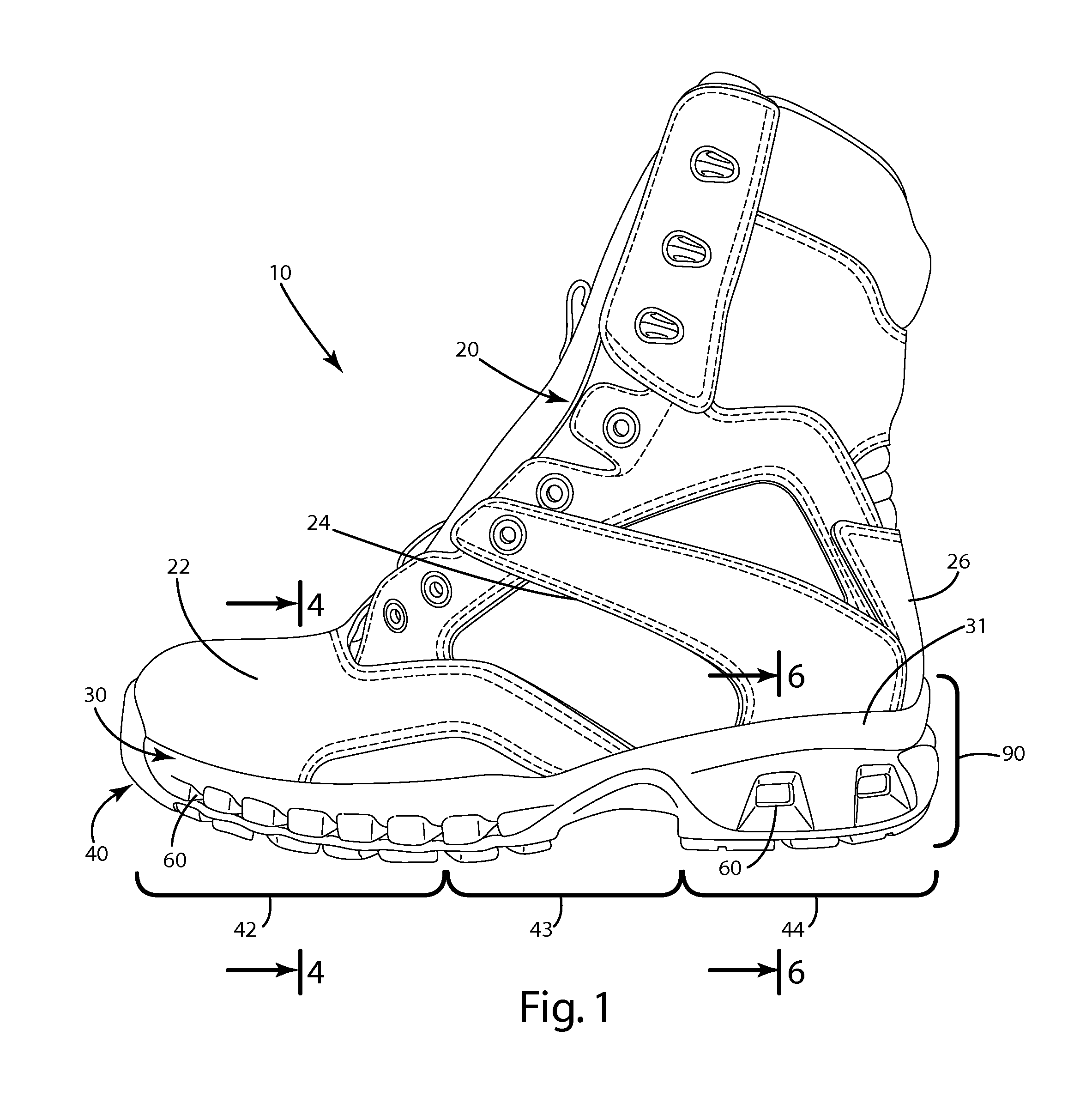

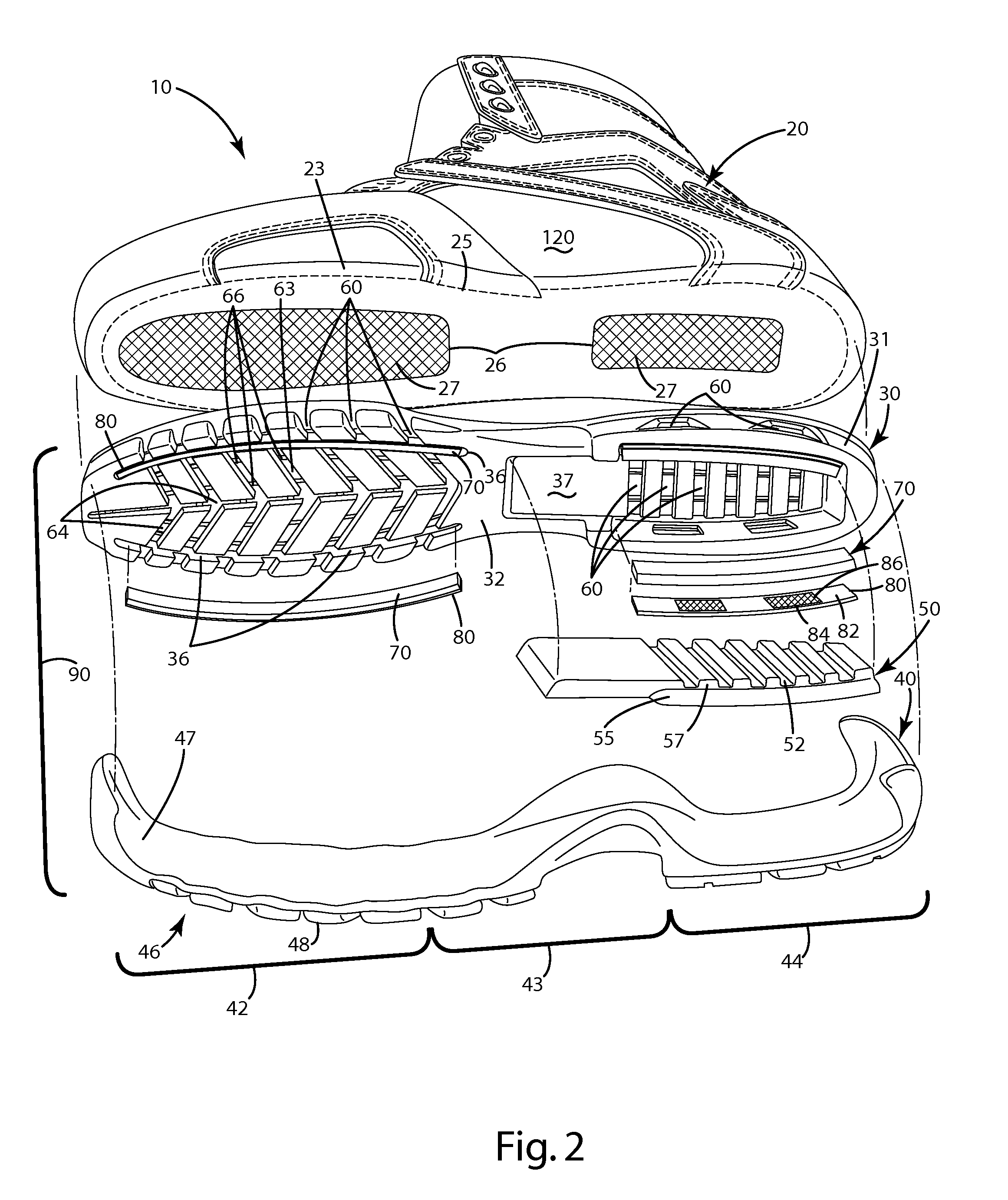

Image

Examples

first alternative embodiment

IV. First Alternative Embodiment

[0078]A first alternative embodiment of the footwear is illustrated in FIG. 10. This footwear is similar to the embodiment described above with several exceptions. For example, the sole 280 generally does not include a heel wedge. Instead, it includes a structure having a tray-like or u-shaped barrier element 270 positioned adjacent a secondary element 280. The secondary element 280 can include the mesh screen as described above to prevent debris from entering the footwear. The sole 280 can also define multiple sets of channels 260 and 266. The channel 260 includes an opening 261 defined in a sidewall 231 of the midsole 230. The sole 280 also can include a second larger channel 266 that extends through the outsole 240 as well as a portion of the midsole 230. The lower portion of the barrier element 270 facing the channel 266 can be adjacent a mesh 286 included in the secondary element 280. Optionally, the mesh 286 can be a completely separate element....

second alternative embodiment

V. Second Alternative Embodiment

[0080]A second alternative embodiment of the footwear 310 is generally illustrated in FIG. 11. This embodiment is similar to the embodiments described above with several exceptions. For example, instead of having channels that open through the exterior sidewalls 331 of the midsole 330, this construction can include a large channel 366 opening through the outsole 340 and the lower portion of the midsole 330 to the environment. Like the first alternative embodiment described above, a barrier element 370 can be positioned adjacent a secondary element 380. A mesh screen 386 can be positioned immediately adjacent the barrier element to prevent dirt and debris from entering the barrier element and / or the interior 120 of the footwear. The barrier element 370 can be of a generally planar configuration, in the form of a widened strip or sheet, extending across the channel 366. When dry, the barrier element allows air to travel through the channel 366 from the ...

third alternative embodiment

VI. Third Alternative Embodiment

[0081]FIG. 12 generally illustrates a third alternative embodiment of the footwear 410, which is similar to the above embodiments with several exceptions. For example, the midsole 430 and the sole 480 in general can define channels 460 extending inwardly from the sidewalls 431. These channels 431 can be in fluid communication with the interior 120 of the footwear 410. A chamber 435 can form a portion of the channels 460 as desired. The barrier element 470 can be positioned within the sidewalls 431. These barrier elements can be of a special configuration and can have a desired geometric cross section, for example, a circular, square, elliptical or other polygonal cross section, that generally matches the geometric cross section of the portion of the channels 460 within which they are positioned. A mesh screen 486 can be embedded in the material of the midsole generally between the opening 461 of the channels and the barrier element 470. The barrier el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com