Magnetic component compiling structure and magnetic refrigerator adapting magnetic component compiling structure thereof

a technology of magnetic refrigerator and compiling structure, which is applied in the direction of refrigeration machines, climate sustainability, machines using electric/magnetic effects, etc., can solve the problems of low volume utilization rate, low material utilization rate, and relatively weak magnetic field casted by permanent magnets, so as to enhance overall working efficiency, enhance cooling efficiency, and enhance working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

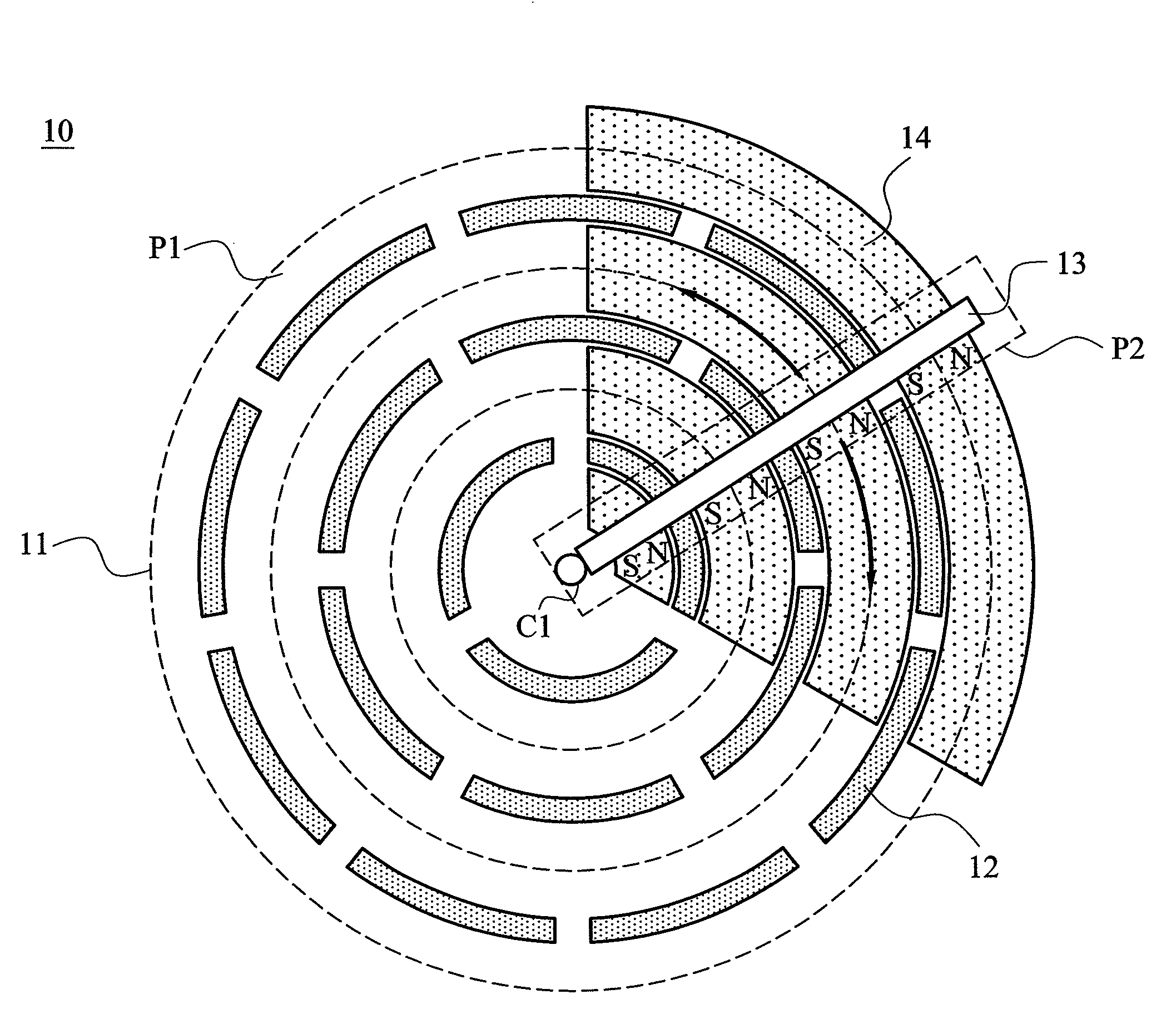

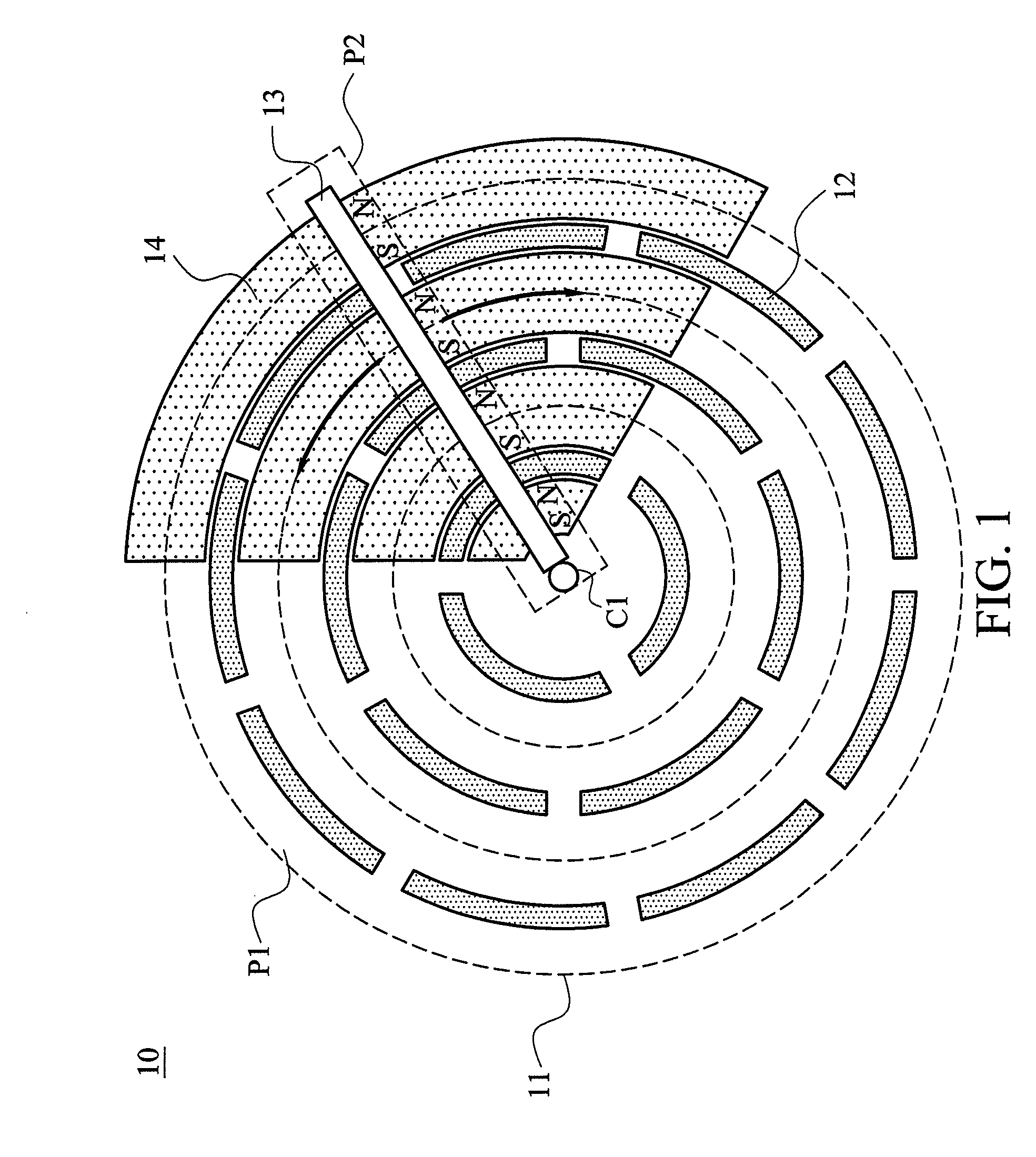

[0022]In the present invention, there discloses a single layer magnetic component compiling structure, please refer to FIG. 1, wherein the magnetic component compiling structure 10 comprises at least a plurality of first magnetic components 12, a shaft 13, and a plurality of second magnetic component 14. The first magnetic components 12 are separately disposed with intervals along peripheries of a plurality of concentric circles 11, wherein the concentric circles 11 are defined by a center C1 on a first plane P1 with different radius, and wherein the first magnetic components 12 are adapted to be disposed in different phases.

[0023]The shaft 13 is fixed at and end to a center on a second plane P2, wherein the second plane P2 is slightly far away from the first plane P1, that is, the center of the second plane P2 and the center of the first plane P1 are adapted to be disposed, for example, in line vertically with a finite distance. The second magnetic components 14 are adapted to be s...

second embodiment

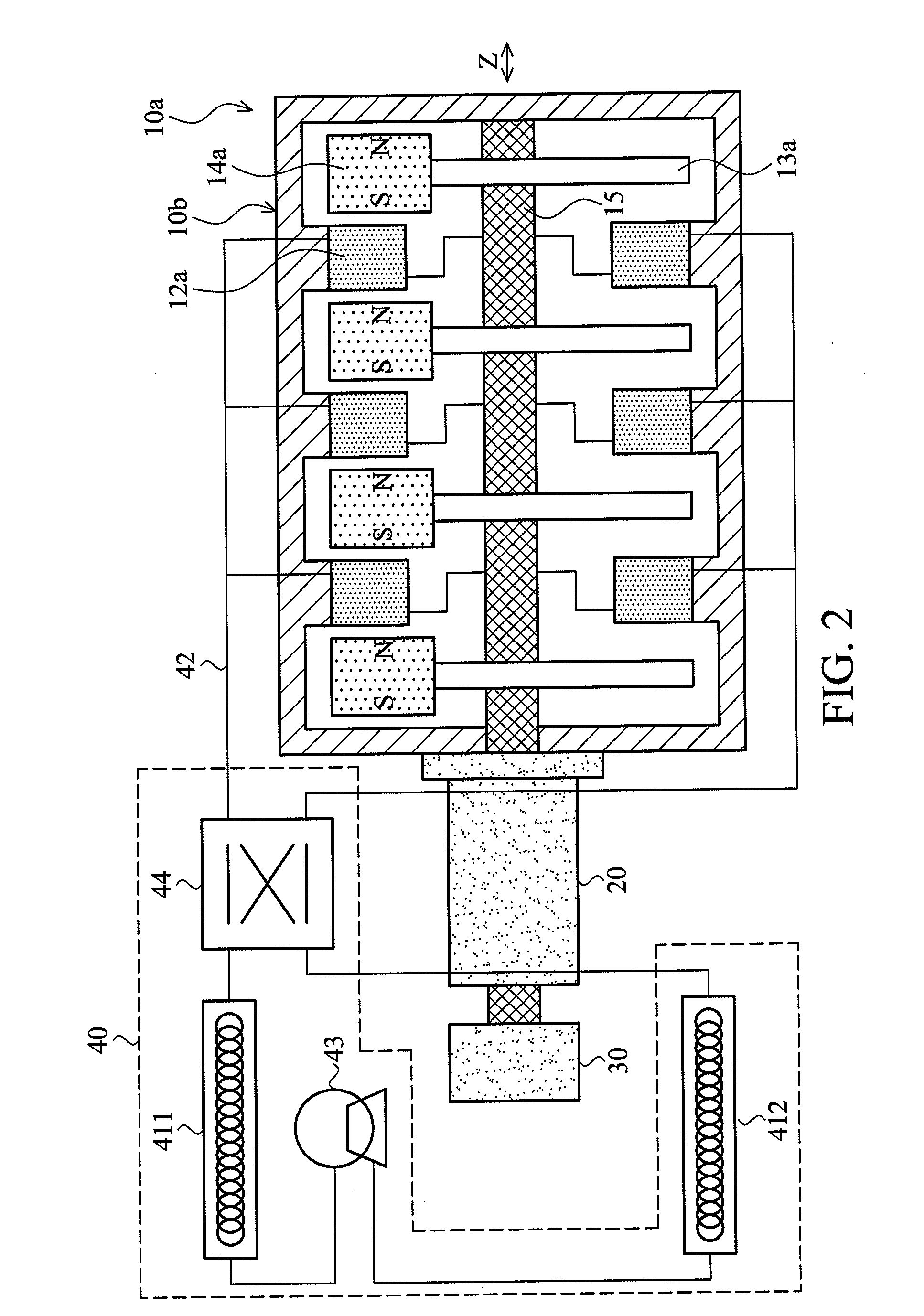

[0027]In the present invention, there discloses a multiple layers magnetic component compiling structure, please further refer to FIG. 2, a schematic view of a magnetic refrigerator according to an embodiment of the present invention, wherein the magnetic component compiling structure 10a comprises at least a central axis 15 and a plurality of magnetic component compiling sets 10b. The central axis 15 extends, for example, along a direction Z, wherein the direction Z can be defined as a vertical or horizontal direction in this specification hereafter in other embodiment.

[0028]The magnetic component compiling sets 10b are adapted to the central axis 15 along the direction Z with different heights, wherein each magnetic component compiling set 10b comprises a plurality of first magnetic components 12a, a shaft 13a, and a plurality of second magnetic components 14a as mentioned, such that the arrangement of each magnetic component compiling set 10b is substantially the same as what the...

third embodiment

[0030]In the present invention, please refer to FIG. 2, the magnetic component compiling sets are adapted to a magnetic refrigerator, wherein the magnetic refrigerator comprises at least a magnetic component compiling structure 10a, a driving mechanism 20, a controlling mechanism 30, and a heat exchanging mechanism 40. The magnetic component compiling structure 10a comprises a central axis 15 and a plurality of magnetic component compiling sets 10b as mentioned. The driving mechanism 20 drives the central axis 15 and the shafts 13a so as to make the first magnetic components 12a and the second magnetic components 14a moving relatively, while the controlling mechanism 30 controls the driving mechanism 20 to drive the central axis 15 and the shafts 13a. The heat exchanging mechanism 40 is connected to the first magnetic components 12a and thus exchanging heat with the first magnetic components 12a, wherein the first magnetic component 12a is adapted to generate MCE as mentioned.

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com