Fiber optic end face inspection probe and system

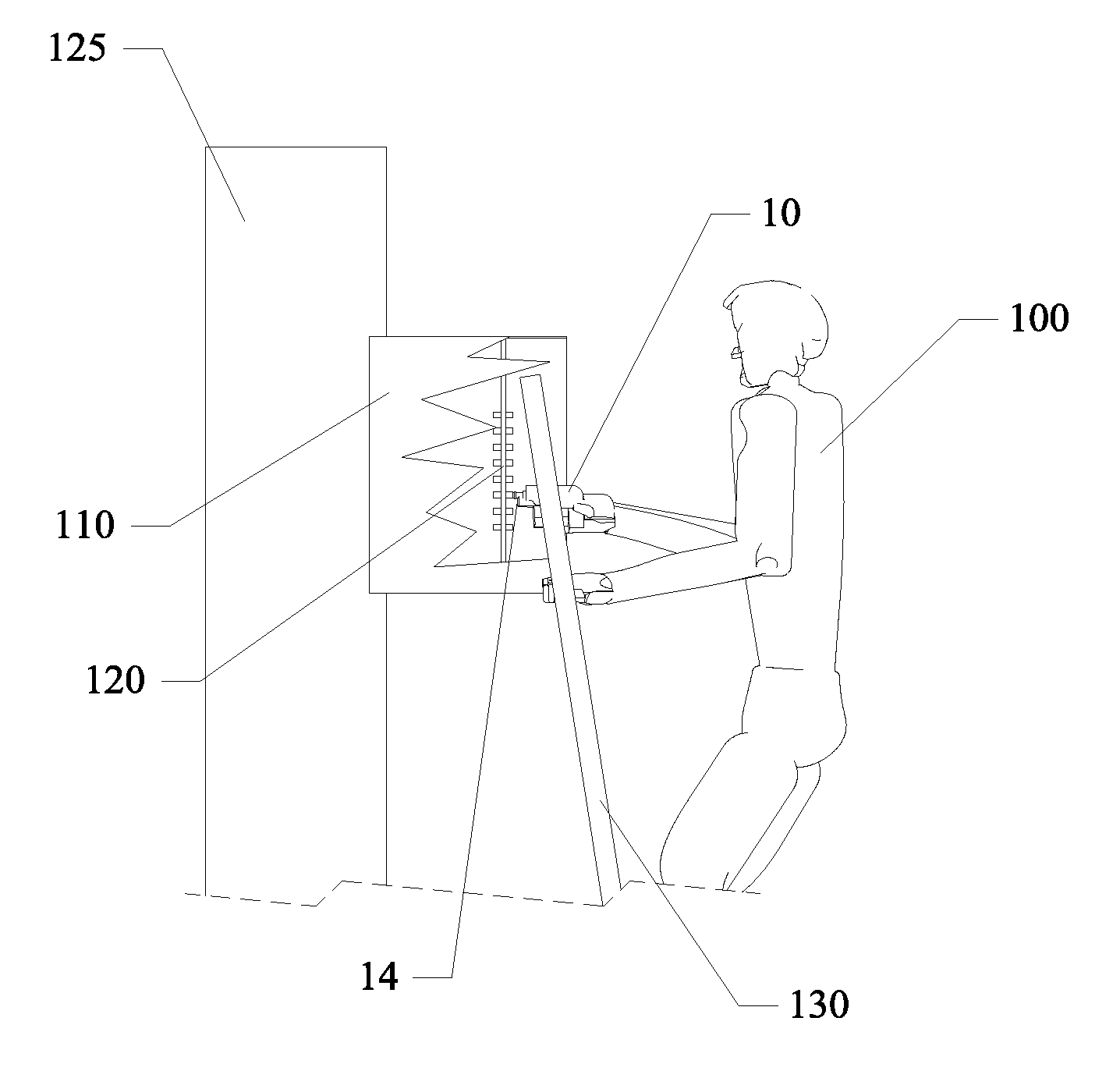

a fiber optic end face and probe technology, applied in the direction of testing fibre optic/optical waveguide devices, instrumentation, structural/machine measurement, etc., can solve the problems of equipment damage, significant back reflection, significant number of fiber optic system failures, etc., and achieve the effect of easy operation and quick and easy use of a single hand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

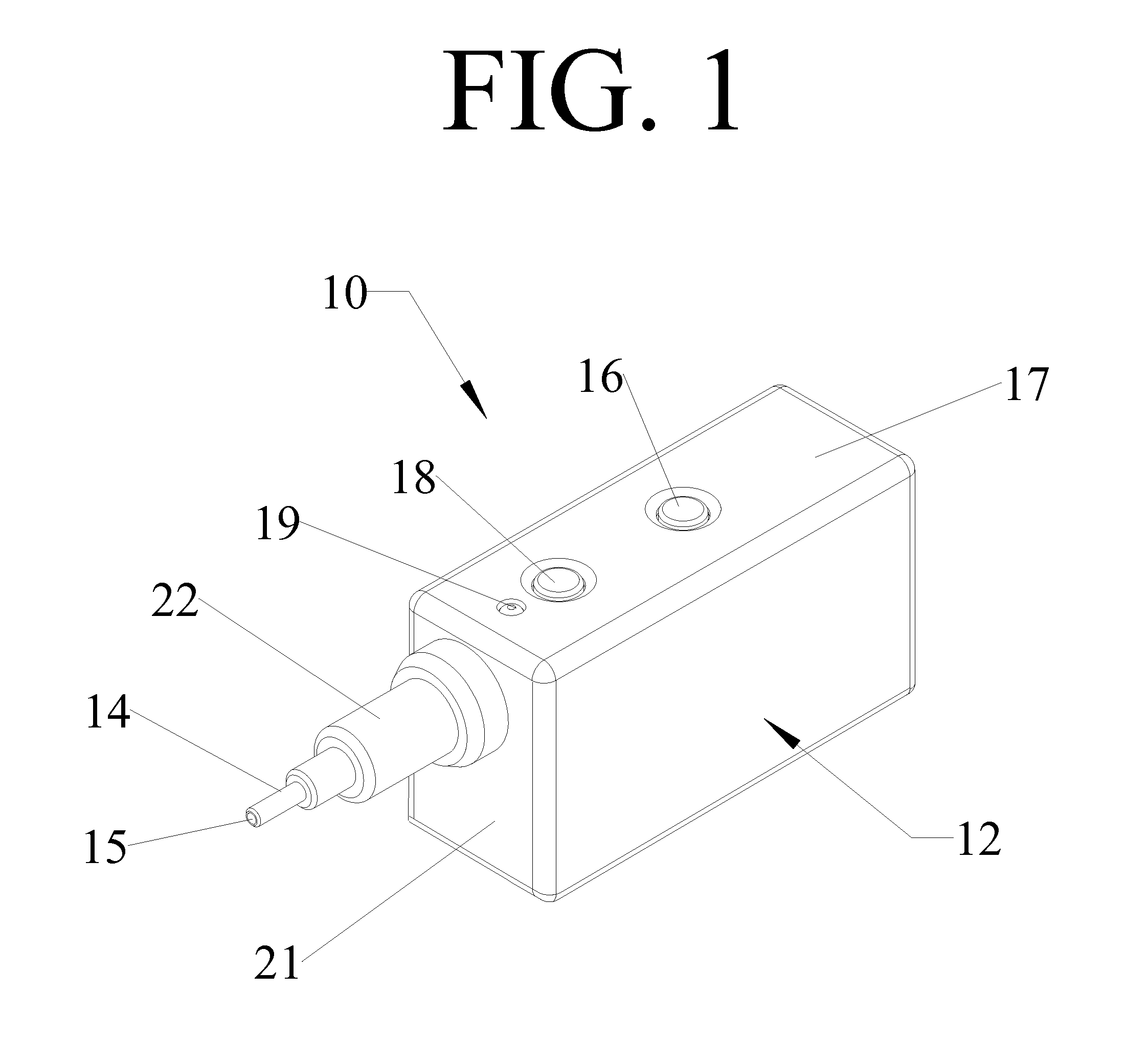

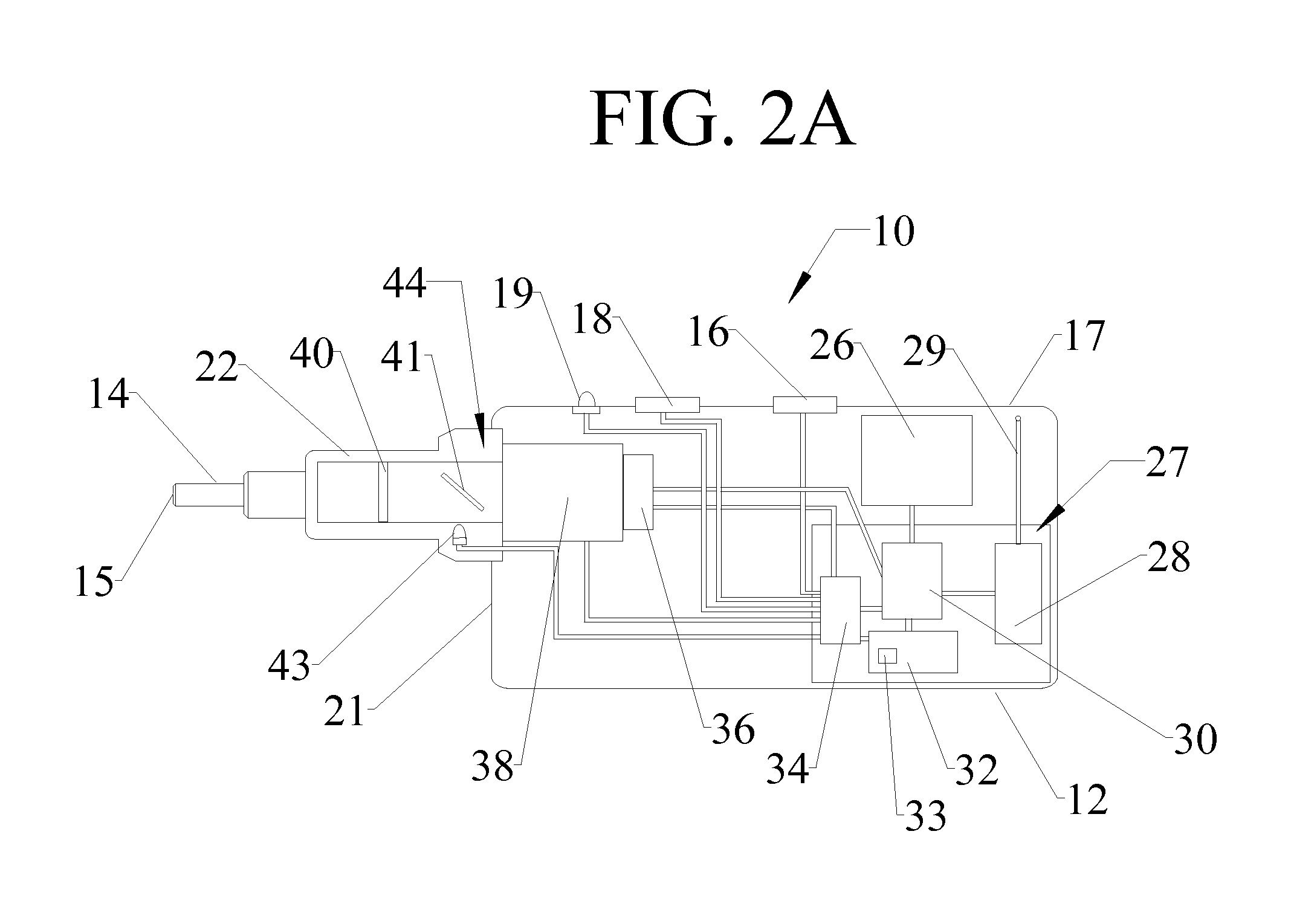

The fiber optic end face inspection probe of the present invention includes many of the same features as those commonly used in the art of fiber optic end face inspection probes. Examples of such fiber optic end face inspection probes include the JDSU FBP-P1 Video Inspection Probe, the AFL Telecommunications Noyes® VFS2 View Safe Video Microscope, and the EXFO FIP-400 Fiber Inspection Probe. These fiber optic end face inspection probes are handheld devices that may be applied to a fiber optic end face to be inspected for imperfections. The principal difference between the fiber optic end face inspection probe of the present invention and fiber optic end face inspection probes commonly used in the art is that prior art probes use video, which must be manually focused to assess the condition of the fiber optic end face. Further, because of the power requirements inherent in video based devices, these probes have heretofore been tethered to a separate viewing device that houses a large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| insertion loss | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com