Mattress assembly with convertible topper

a mattress and convertible technology, applied in the field of mattress assembly with convertible topper, can solve the problems of increasing the difficulty of placing the most comfort forming material (specifically, the fibrous material) in a permanently attached pillowtop, the sheer size and weight of the mattress, and the addition of a significant amount to the cost of the mattress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

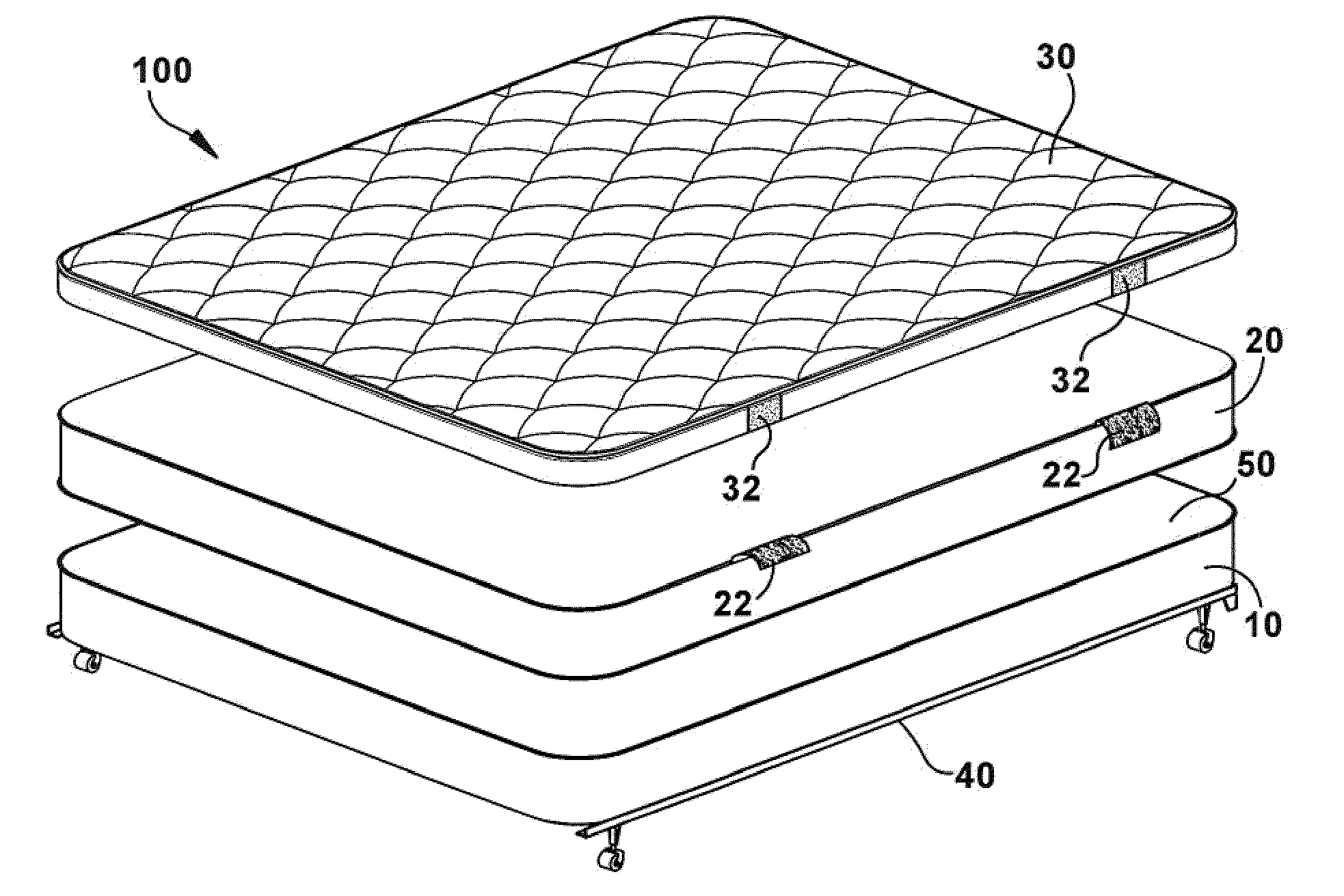

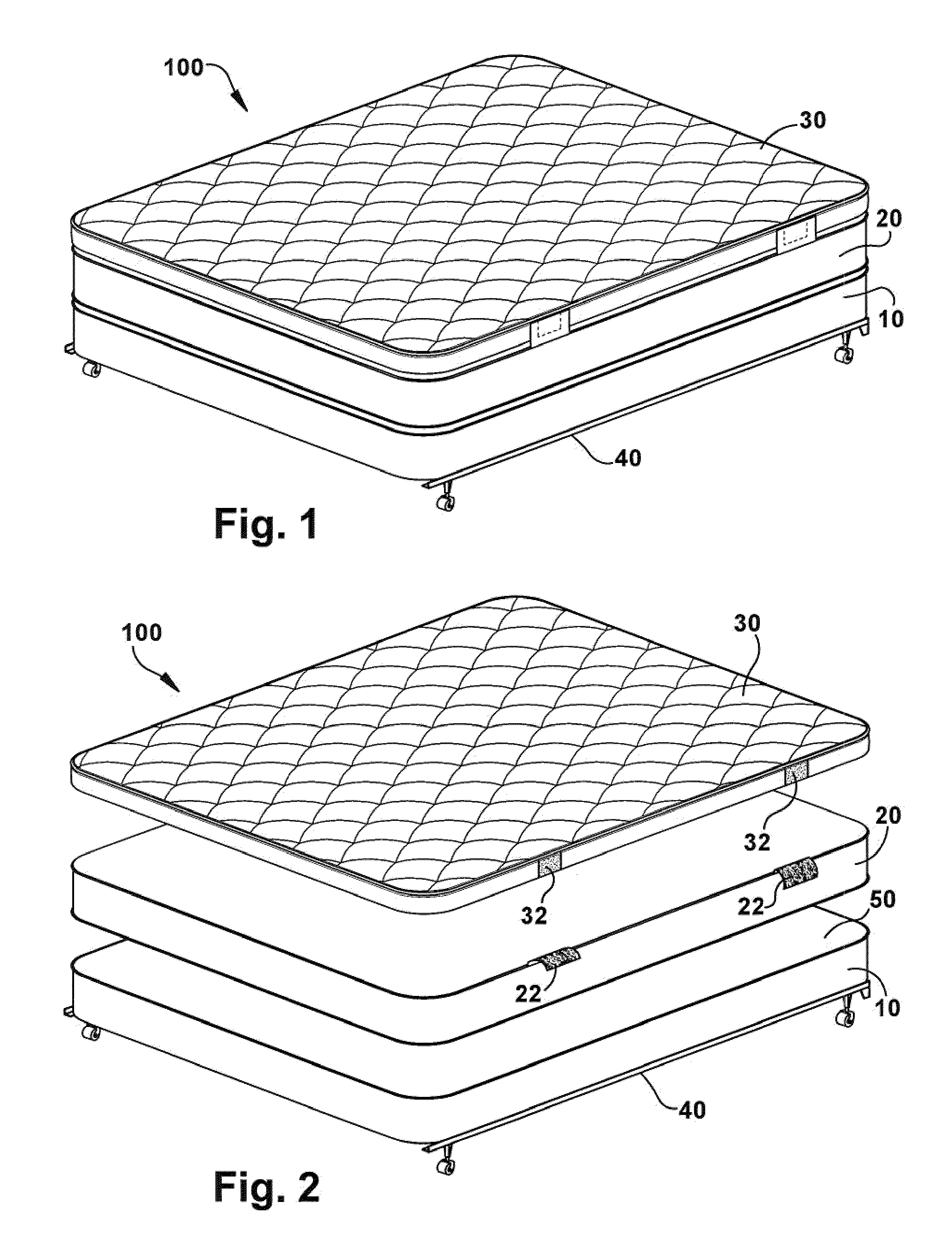

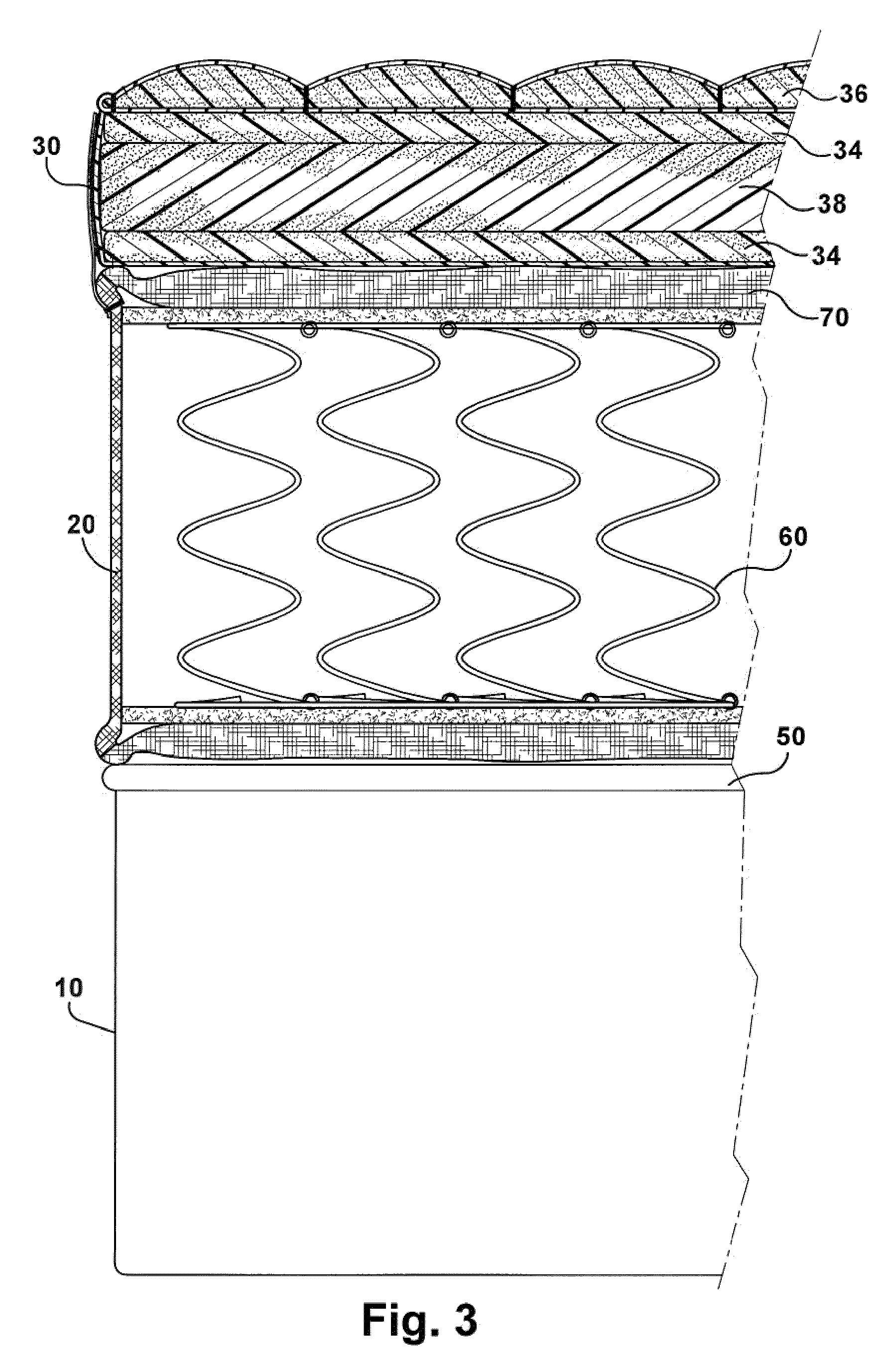

[0013]FIG. 1 shows a mattress assembly with convertible topper sleep system of the present invention 100, which includes a foundation unit 10, a support unit or innerspring 20, and a comfort unit or pillowtop 30. The foundation unit 10 can be of conventional internal design and construction, having a rectangular frame on which are mounted a plurality of spring elements or modules (not shown) to provide flexible support for an overlying grid (not shown) which defines the foundation surface 50. The spring module may be formed of wire or made of composite material. Alternatively, the foundation unit 10 can be made entirely of wooden materials. This design eliminates metal-to-metal contact, thus reducing noise and also provides a stronger, more durable bed foundation. The wooden foundation unit also provides high sway resistance and prevents uncomfortable sinking and sagging where weight is concentrated. The wooden unit also ensures longer life, making such foundation appropriate for hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com