Compressible Liner for Impact Protection

a compression liner and impact protection technology, applied in chemical protection, nuclear engineering, nuclear elements, etc., can solve the problems of not considering or discussing the combination of structural elements, the single density foam liners used in current helmets are too hard and too stiff to effectively absorb impact force, and the single density foam liners are also limited in their ability to accommodate the variation in strength about the human skull, etc., to achieve low resistance to impact, increase the resistance to impact, and reduce the effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

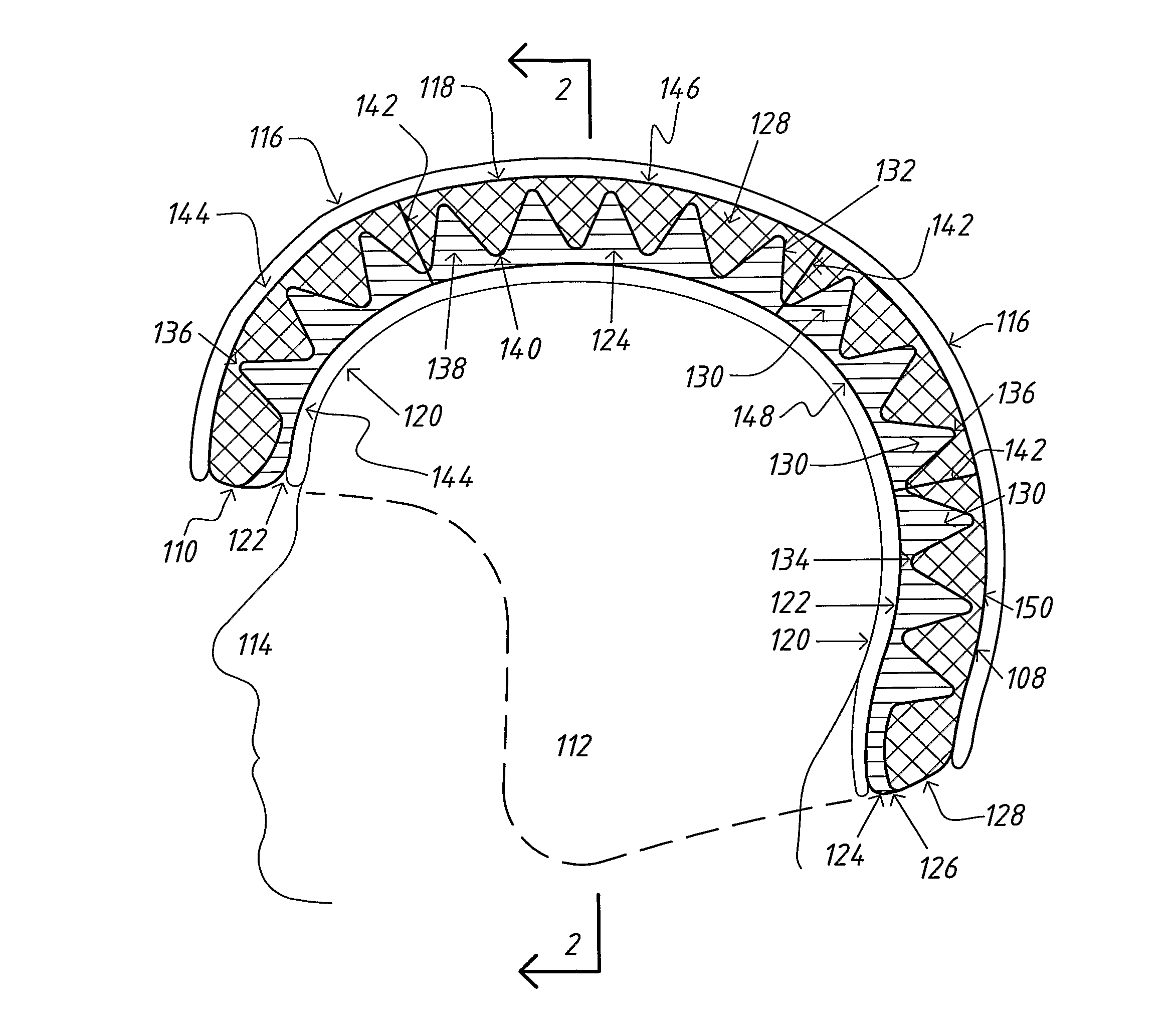

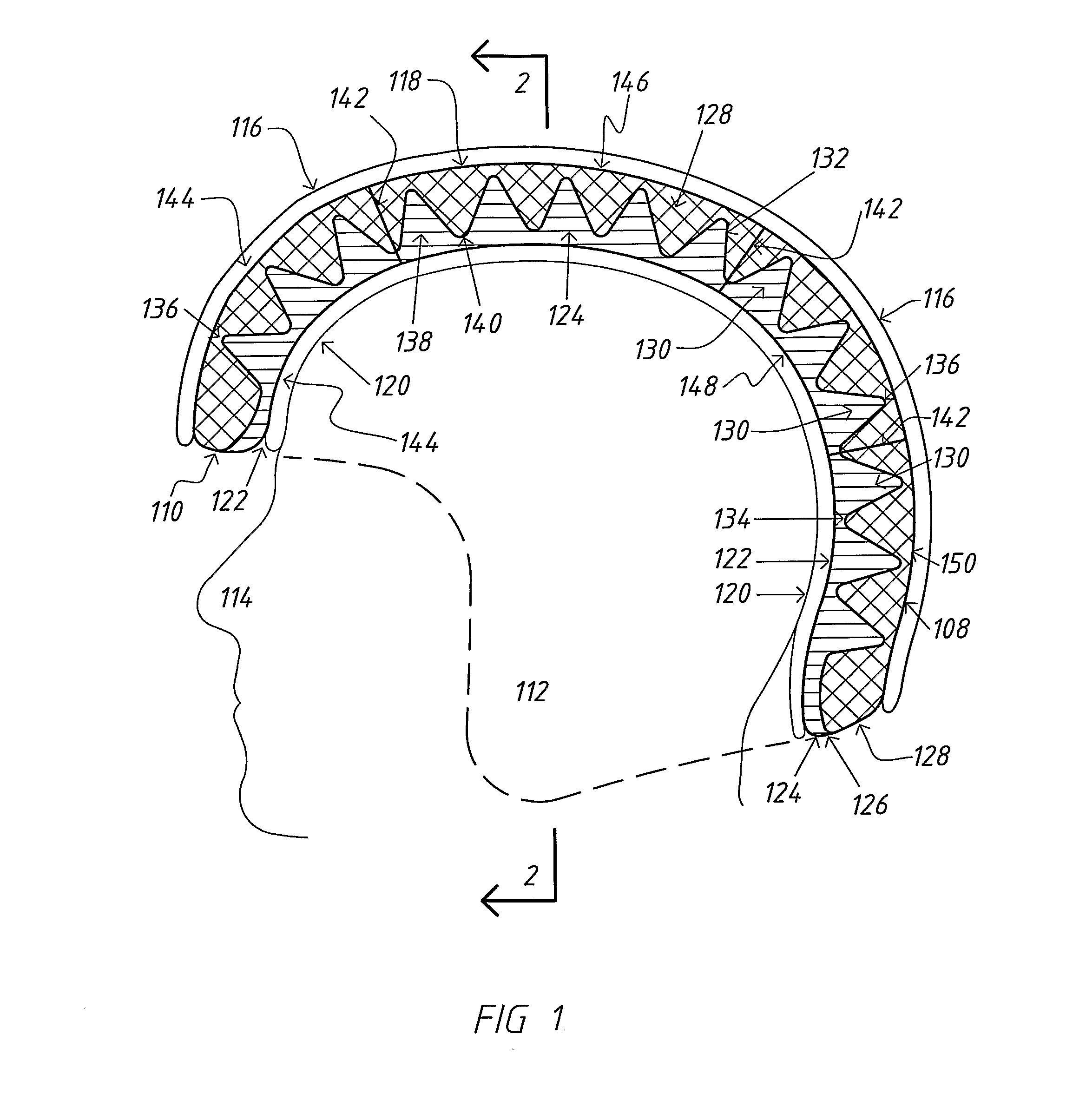

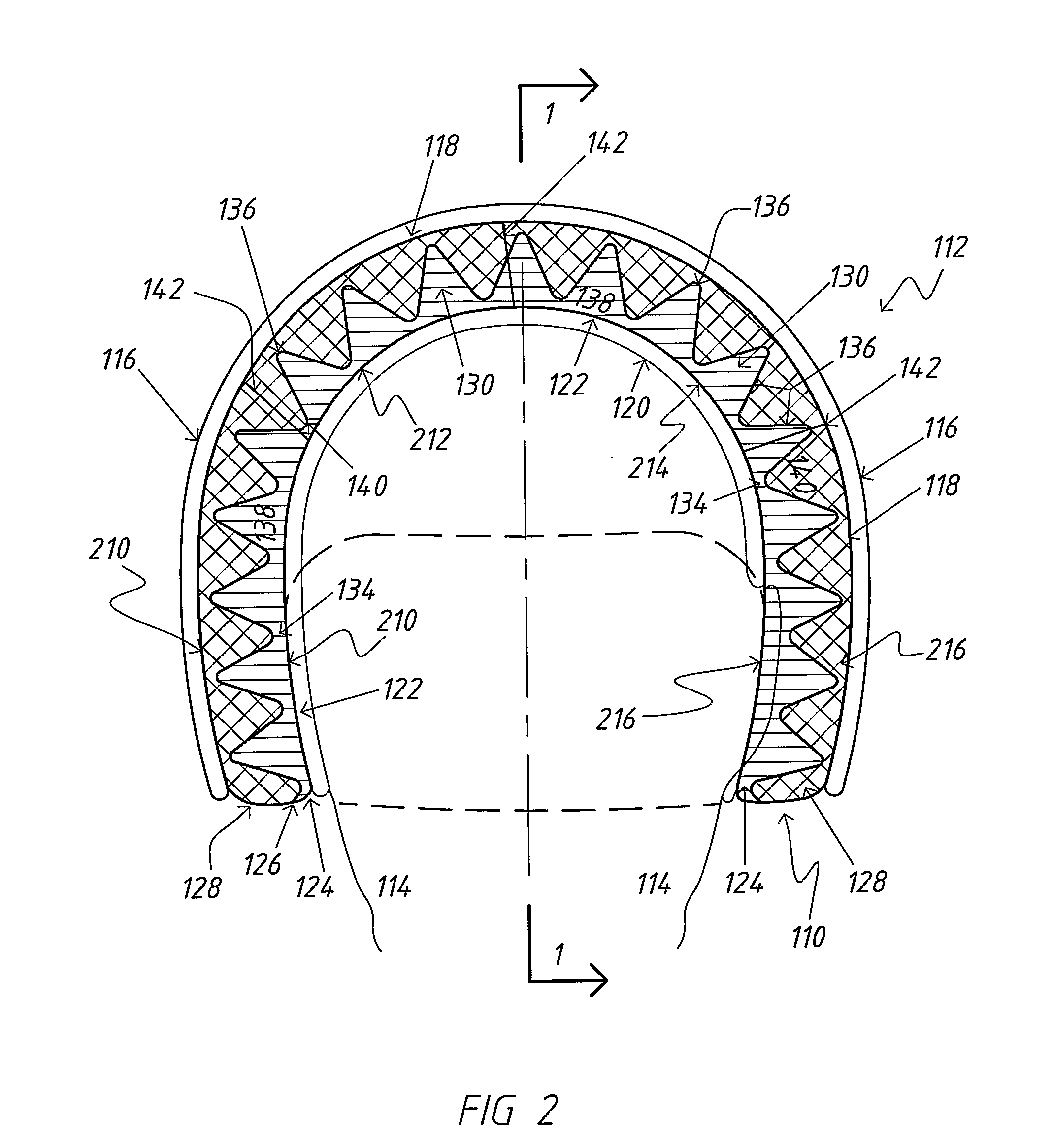

[0043]Reference is first made to FIGS. 1 and 2 which are orthogonal cross-sectional views, schematically showing a first embodiment of a compressible liner 110 installed in a helmet 112 worn by a person 114. The helmet 112 may include a hard outer shell 116 against the outer surface 118 of the compressible liner 110 and also may include a comfort liner 120 against the contact surface 122 of the compressible liner 110. If a comfort liner 120 is present then it is appreciated that the head is immediately adjacent the contact surface 122 via the comfort liner 120. If the comfort liner is not present the contact surface 122 engages the head directly.

[0044]The compressible liner 110 may have a relatively low density foam inner layer 124 fused, adhered or otherwise attached at respective joining surfaces 126 to a relatively high density foam outer layer 128, where the lower density foam is more easily compressed than the higher density foam. That is, the first material forming the inner l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com