Dressing jig for glass substrate polishing pad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Working Example

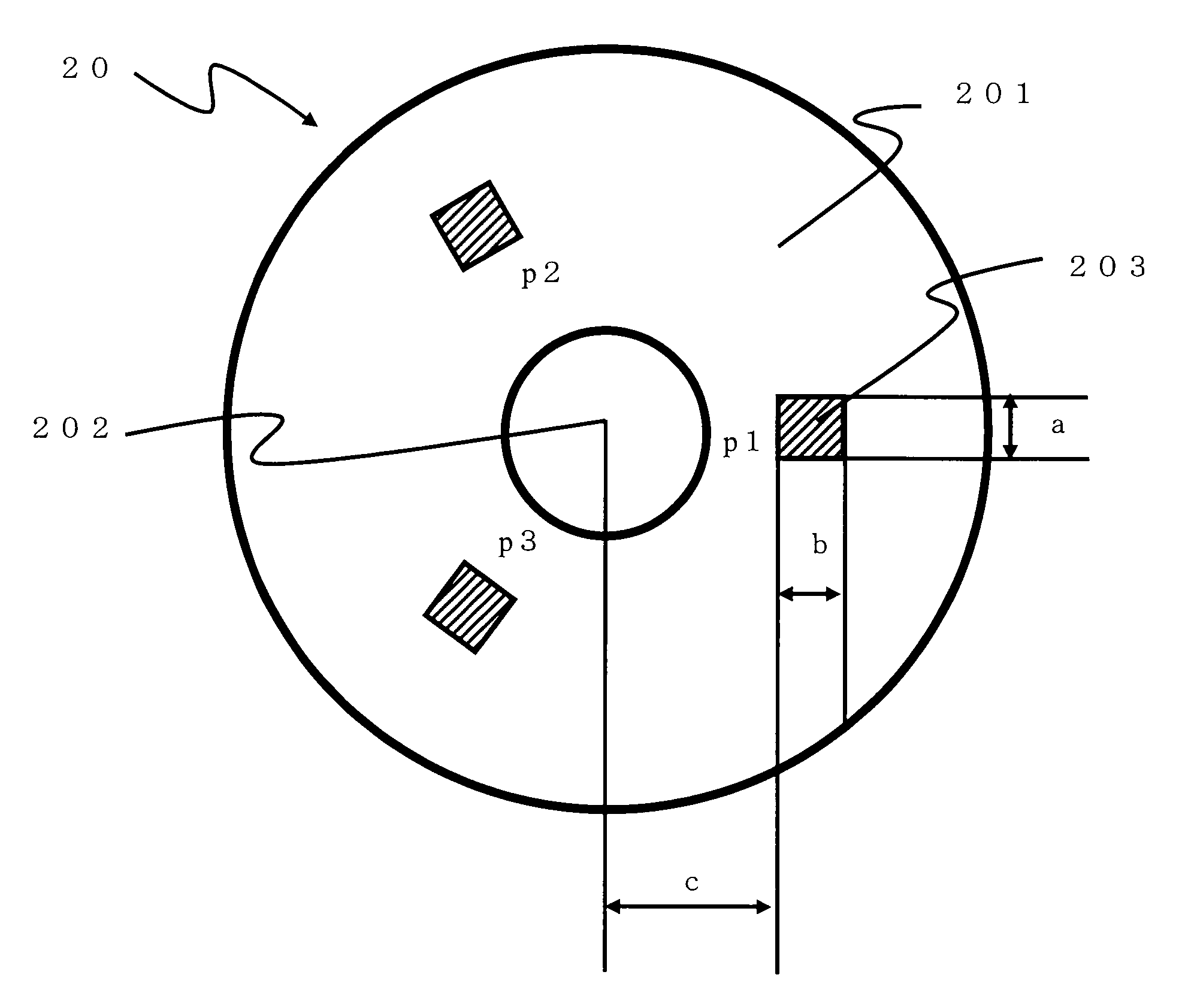

[0069]Dressing treatment of a polishing pad was conducted using a disk-like glass substrate (diameter: 65 mm) having an average surface roughness Ra of 1.25 μm, comprising SiO2 as a main component as a dressing jig, thereby conducting finish polishing of a glass substrate for a magnetic recording medium. The dressing treatment was carried out while supplying a dressing liquid containing colloidal silica (colloidal silica having an average grain size of primary particles of from about 20 to 30 nm). The average surface roughness Ra of the dressing jig after the dressing treatment was 0.35 and an amount of change of the average surface roughness Ra before and after the dressing treatment was 72%. The average surface roughness Ra of the polishing surface of the polishing pad after the dressing treatment was 1.85 μm.

example 2

Comparative Example

[0070]The dressing treatment was conducted in the same manner as in Example 1, except for using a disk-like glass substrate having an average surface roughness Ra of 0.08 μm as the dressing jig, thereby conducting finish polishing of a glass substrate for a magnetic recording medium. The average surface roughness Ra of the dressing jig after the dressing treatment was 0.07 μm, and an amount of change of the average surface roughness Ra before and after the dressing treatment was 13%. The average surface roughness Ra of the polishing surface of the polishing pad after the dressing treatment was 2.45 μm.

example 3

Comparative Example

[0071]The dressing treatment was conducted in the same manner as in Example 1, except for using a dressing jig having an average surface roughness Ra of 2.75 (#600 diamond dressing jig) as the dressing jig, thereby conducting finish polishing of a glass substrate for a magnetic recording medium.

[0072]The average surface roughness Ra of the polishing surface of the polishing pad after the dressing treatment of Example 1 could be adjusted low as compared with Example 2 which is Comparative Example. It is presumed from this fact that the present dressing jig can conduct a stepwise dressing treatment by one dressing jig as if the dressing treatment was conducted using a plurality of dressing jigs having different average surface roughness Ra by that the average surface roughness Ra greatly changes during the dressing treatment.

[0073]The average surface roughness Ra of the dressing jig and the average surface roughness Ra of the polishing surface of the polishing pad a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com