Multiend package of multifilament polyester bicomponent yarn

a polyester bicomponent, multi-end technology, applied in the direction of transportation and packaging, manufacturing tools, other domestic articles, etc., can solve the problems of multi-end package production in which the yarns are produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Multiend Package of 2 Threadlines of 55 dtex and 34 Filaments

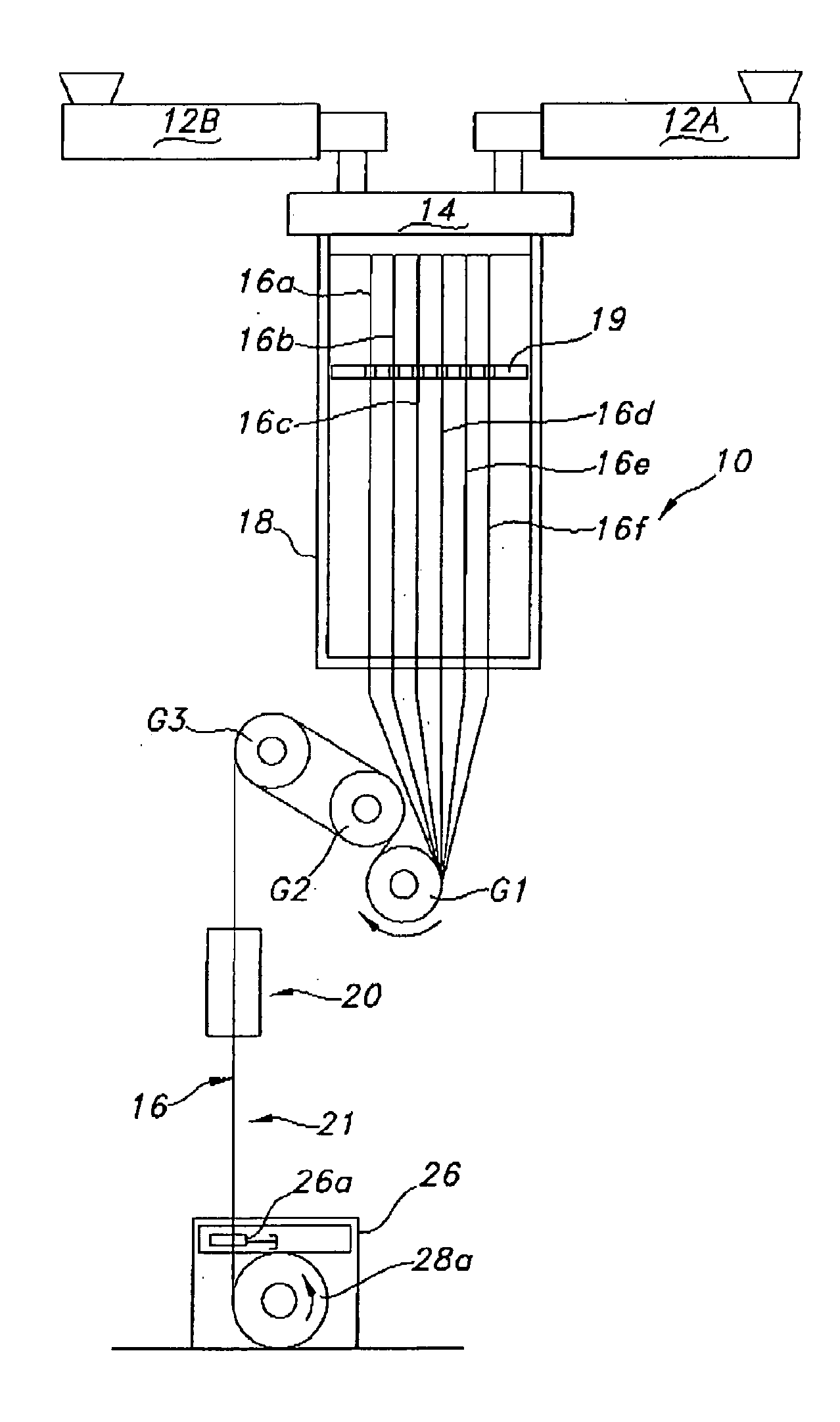

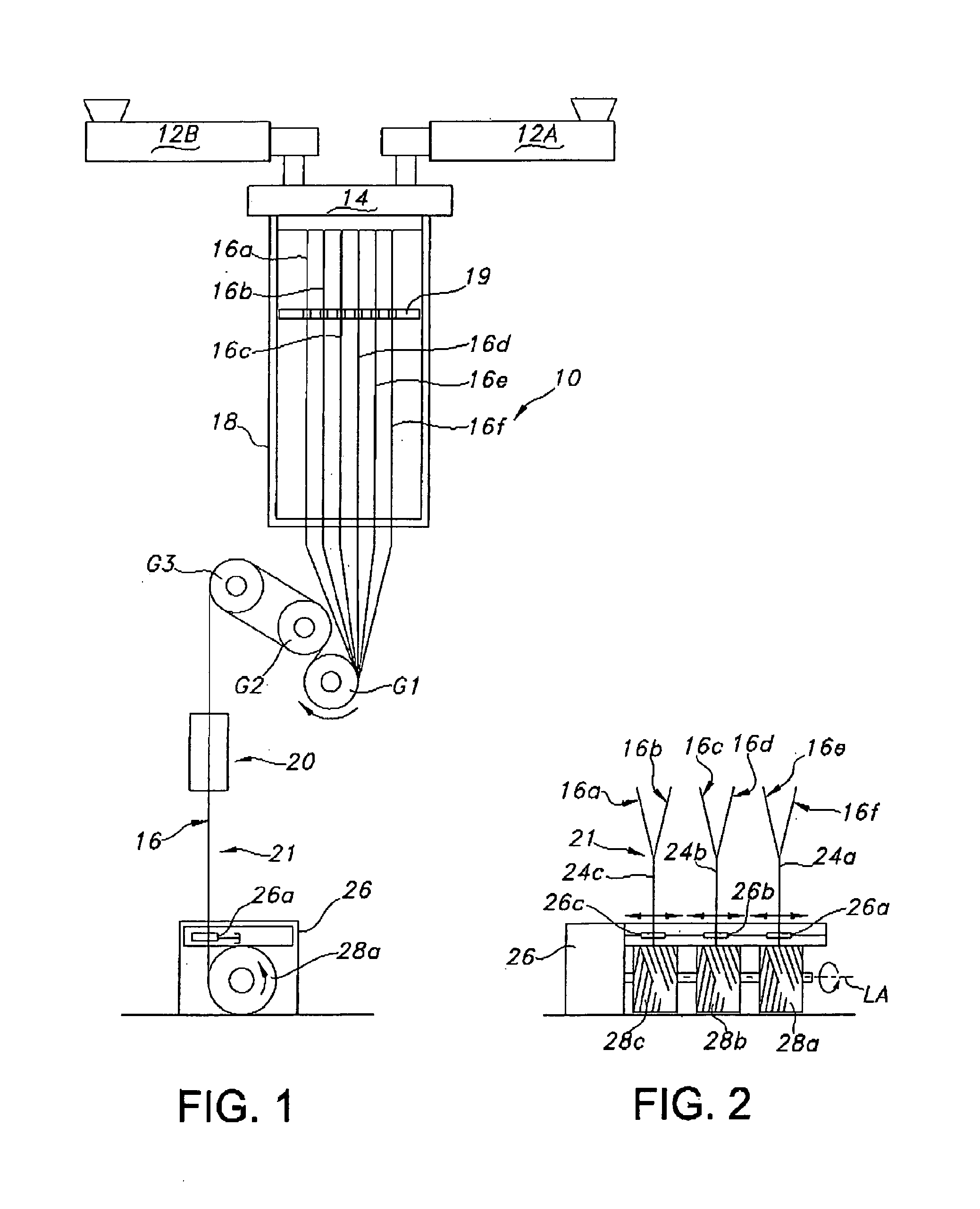

[0052]In order to prepare a multiend package of two threadlines each of 55 dtex and 34 filaments, each threadline with 68 filaments is prepared from a single spinneret and separated into two threadlines with 34 filaments each. Then, each threadline has 34 filaments. For a yarn spinning apparatus with six spinnerets, the six threadlines become twelve threadlines at one spinning position.

[0053]Each threadline (12 total with 34 filaments each) has its own yarn path on rolls and all facilities. All 12 threadlines are independent. After passing through the interlace jet, 2 threadlines converge into one threadline by a convergent guide, then this converged threadline is wound to one yarn package by take up winder. This provides six multiend packages with each having two ends from threadlines having 55 dtex and 34 filaments each.

example 2

Multiend Package of 2 Threadlines of 27 dtex and 17 Filaments

[0054]In order to prepare a multiend package of two threadlines each of 27 dtex and 17 filaments, each threadline with 34 filaments is prepared from a single spinneret and separated into two threadlines with 17 filaments each. Then, each threadline has 17 filaments. For a yarn spinning apparatus with six spinnerets, the six threadlines become twelve threadlines at one spinning position.

[0055]Each threadline (12 total with 17 filaments each) has its own yarn path on rolls and all facilities. All 12 threadlines are independent. After passing through the interlace jet, 2 threadlines converge into one threadline by a convergent guide, then this converged threadline is wound to one yarn package by take up winder. This provides six multiend packages with each having two ends from threadlines having 27 dtex and 17 filaments each.

example 3

Multi-End Package for Core Spinning

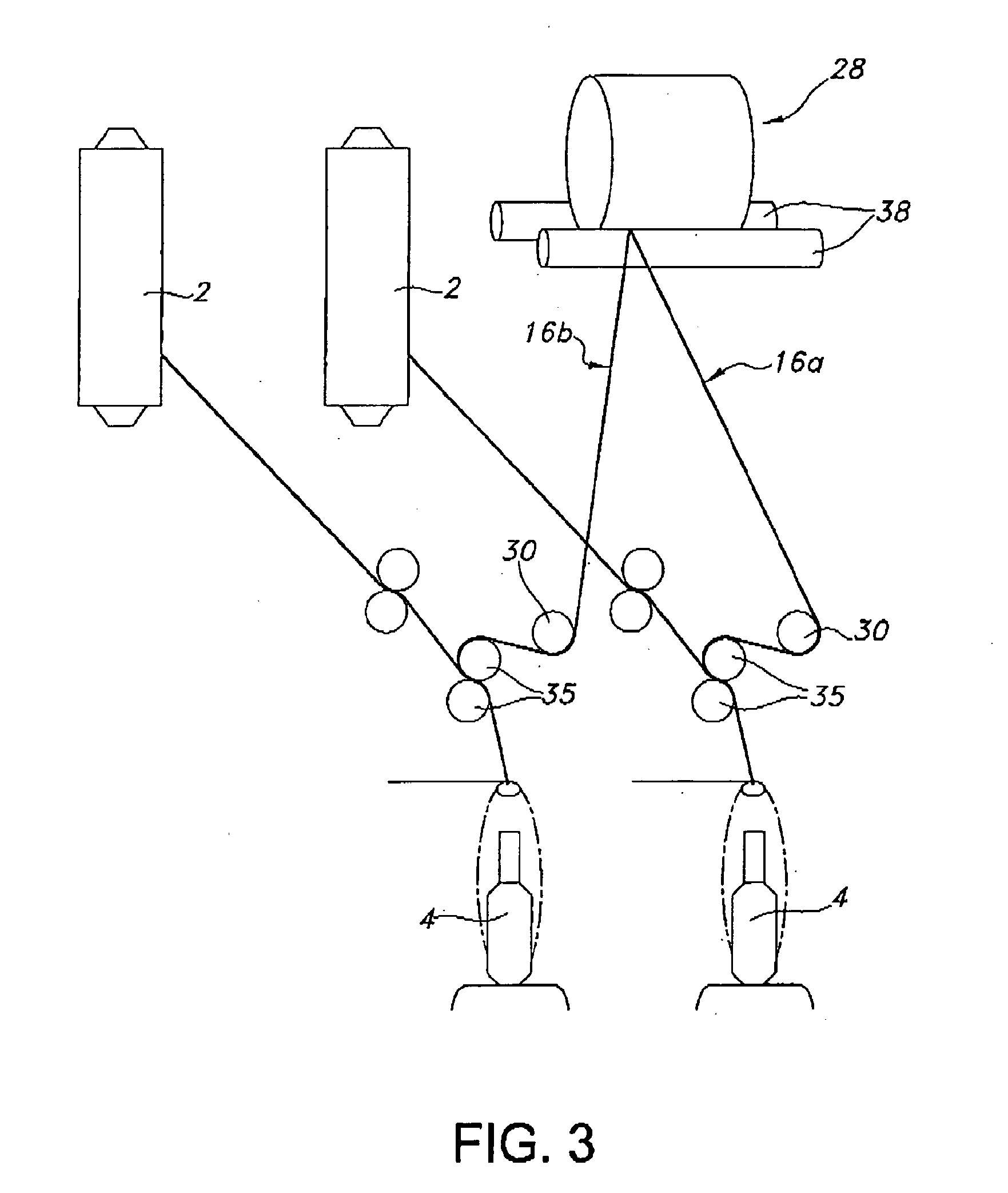

[0056]FIG. 3 shows a multiend package 28c for core spinning process. The yarn is driven by two delivery rollers 38 so that the two multicomponent yarns 16a and 16b from multiend package 28c are separated and unwound tangentially to the roller guides 30 which direct the separated multicomponent yarn 16a and 16b to its corresponding front roller 35 of spinning position where the polyester multiple component yarns are combined with the staple roving fiber 2 to provide separate core-spun yarn packages 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com