Hernia patch

a hernia patch and implantable technology, applied in the field of hernia patches, can solve the problems of affecting the growth of the hernia patch, and the polymer-only materials used in some conventional hernia patches, and achieve the effect of promoting tissue incorporation and in-growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

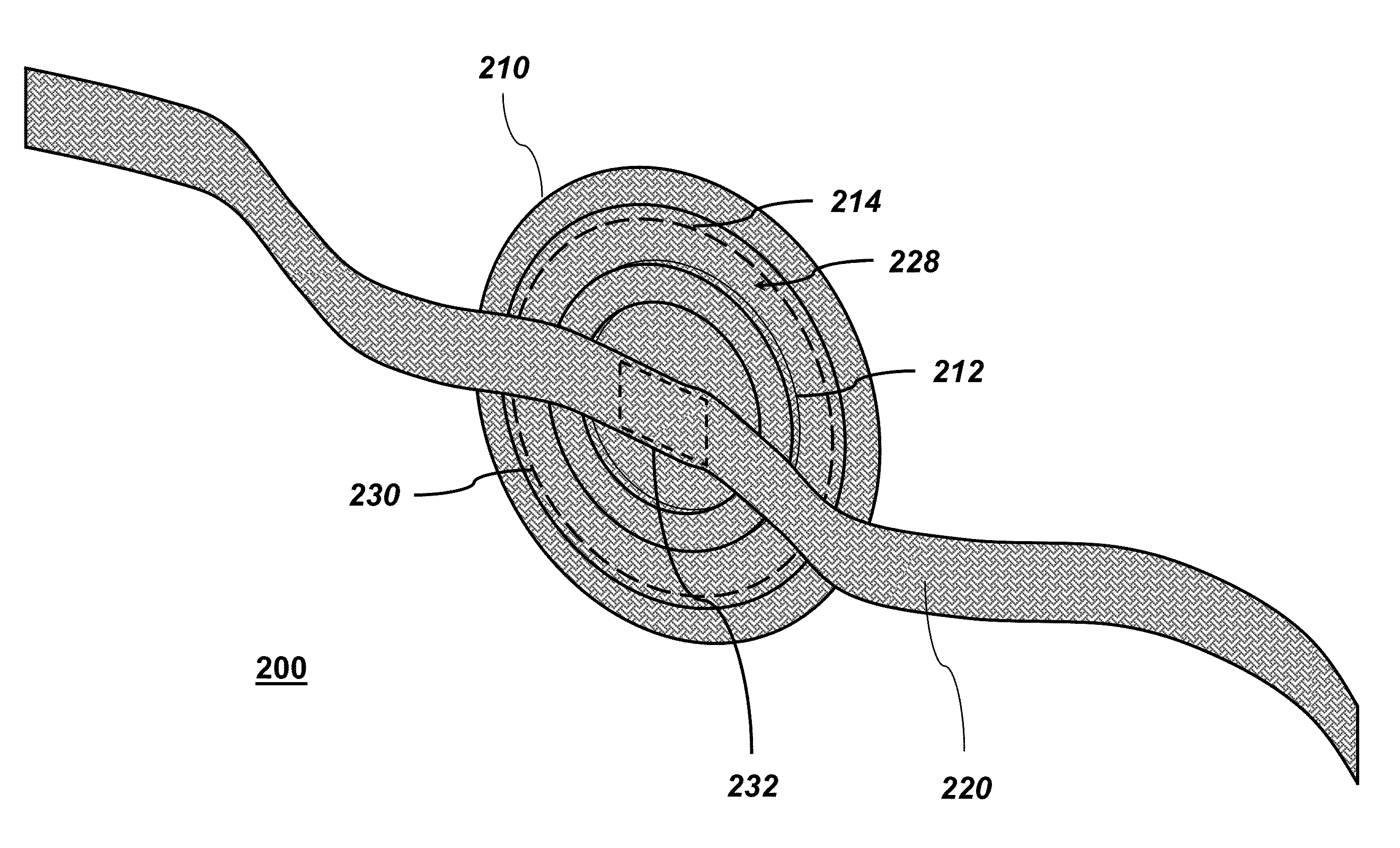

[0038]An illustrative embodiment of the present invention relates to a hernia patch that is efficiently implanted, can be readily pulled and maintained against a tissue wall without undue distortion of the patch, and that readily contours and conforms to the tissue wall, eventually promoting tissue in-growth therethrough.

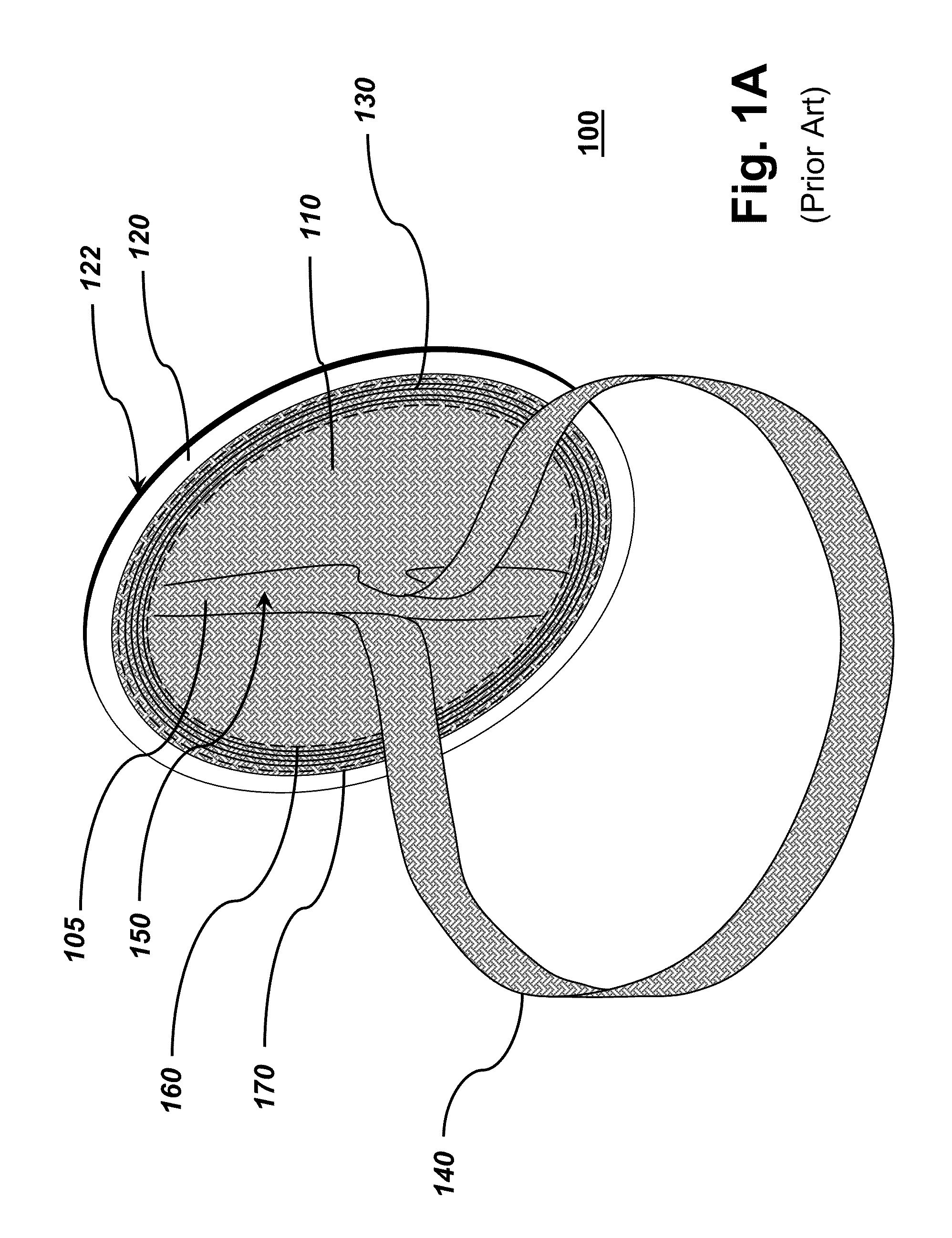

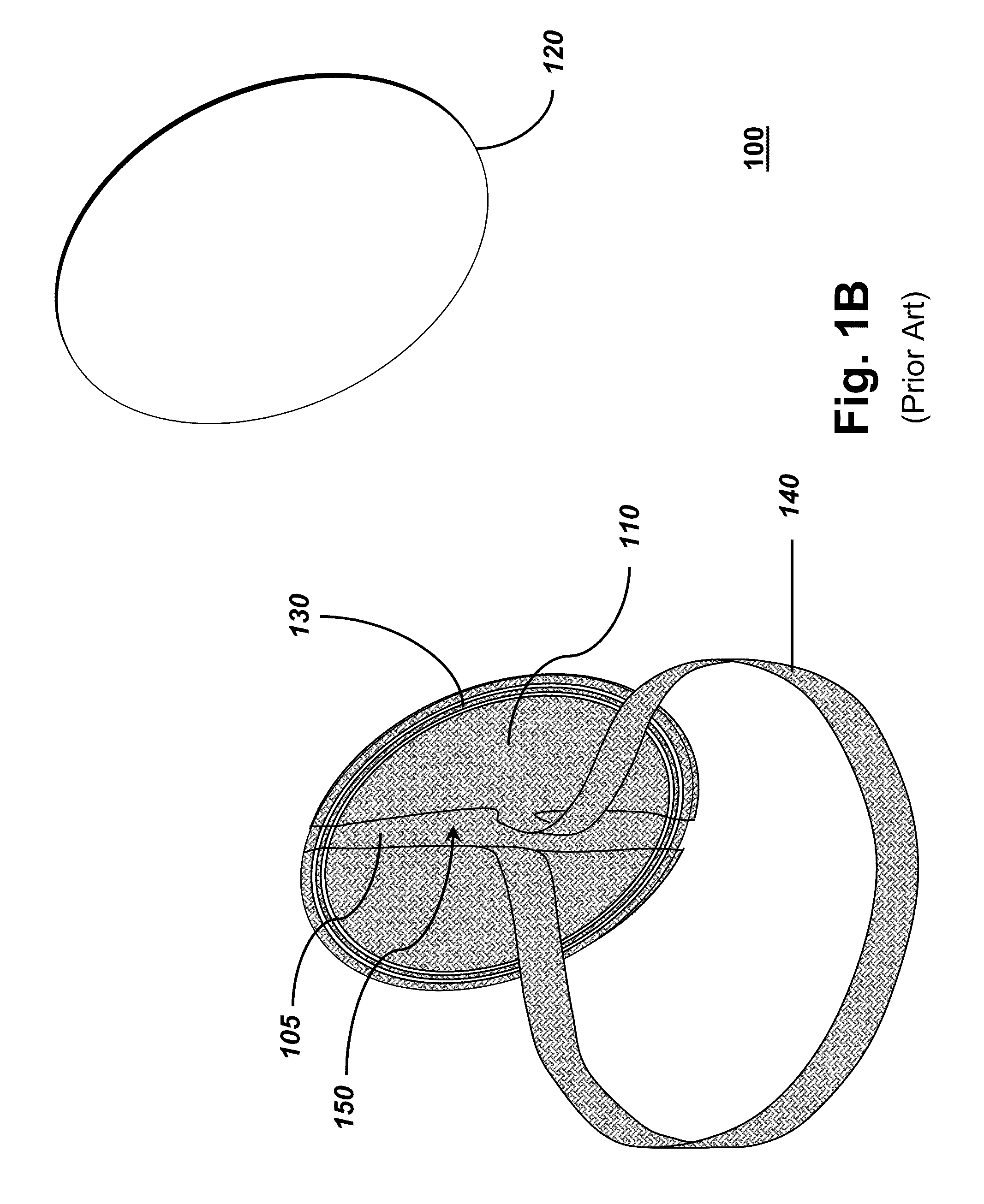

[0039]FIGS. 2 through 6B, 7A and 8A, wherein like parts are labeled with like reference numbers throughout, illustrate example embodiments of a hernia patch according to the present invention. Although the present invention will be described with reference to the example embodiments illustrated in the Figures, it should be understood that many alternative forms can embody the present invention. One of ordinary skill in the art will additionally appreciate different ways to alter the parameters of the embodiments disclosed, such as the size, shape, or type of elements or materials, in a manner still in keeping with the spirit and scope of the present invention.

[0040]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com