Axial flow machine having an asymmetrical compressor inlet guide baffle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

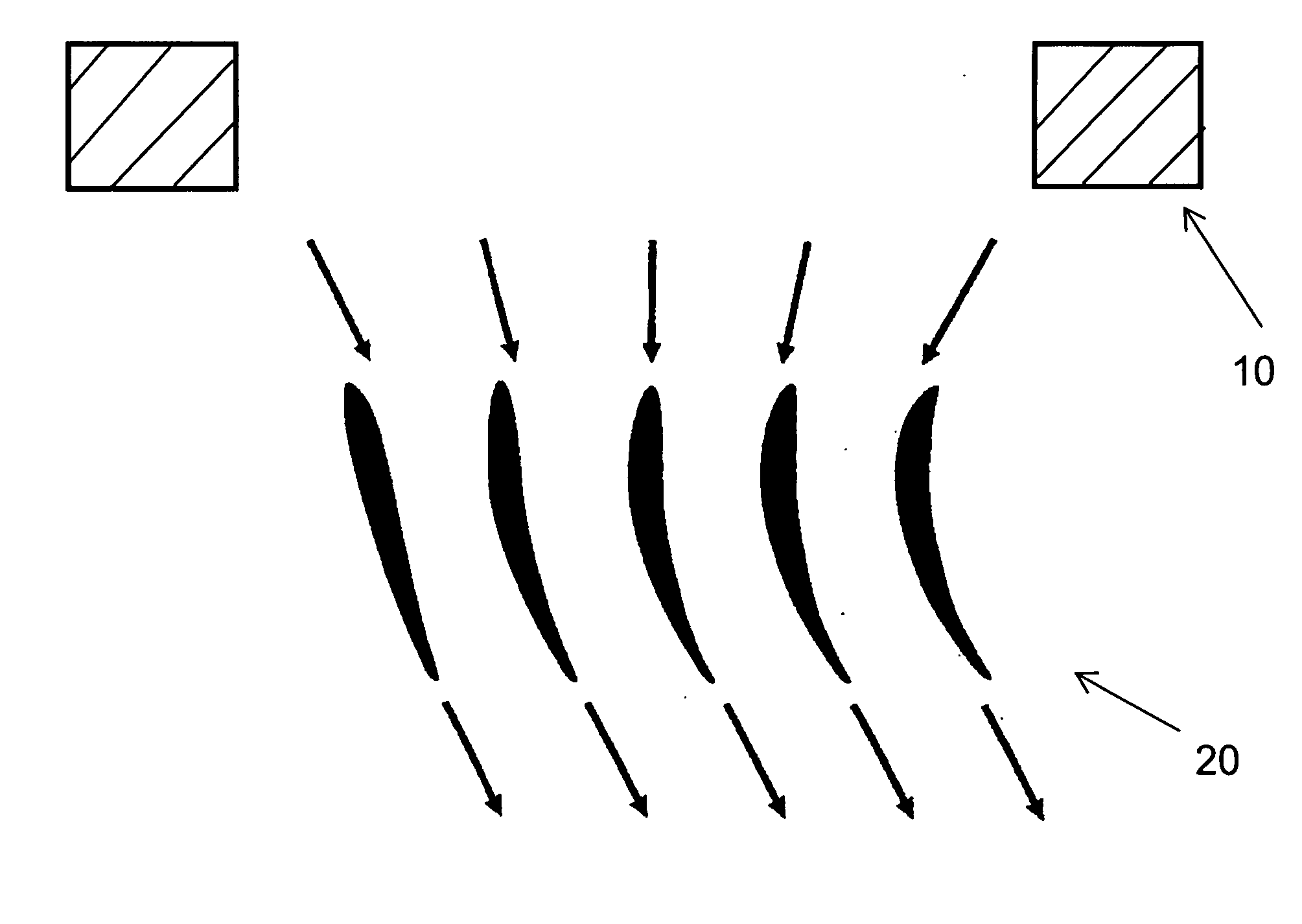

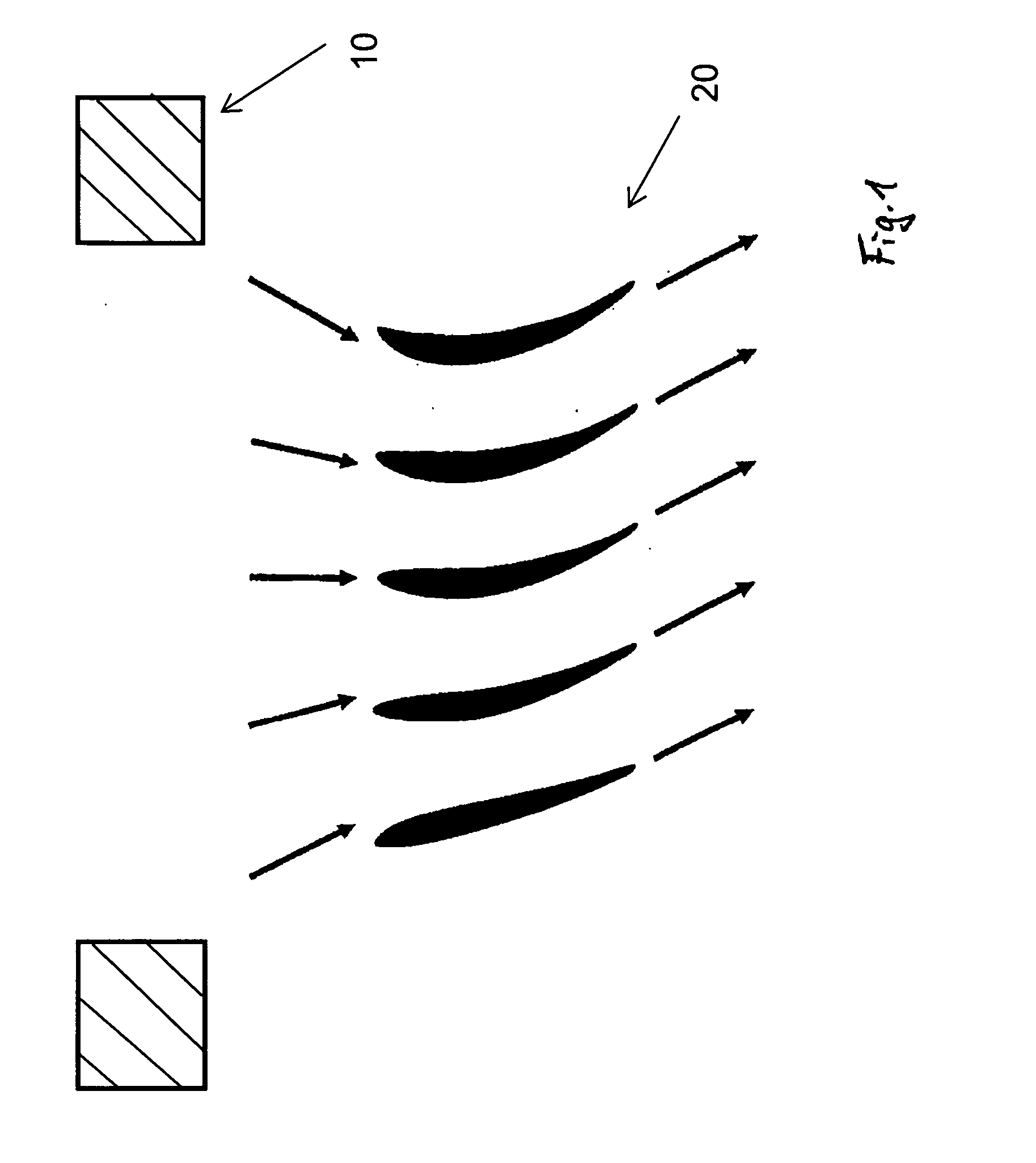

FIG. 1 shows a schematic representation of a developed view of an inlet guide baffle 20 in accordance with the present invention having multiple profiles, i.e., of individual profiling of each individual vane of the inlet guide baffle. In this manner, the vanes are adapted to the variable circumferentially asymmetric angle of incidence of the inlet guide baffle. This asymmetrical incident flow is caused by the asymmetric air inlet 10, shown schematically. The inlet guide baffle according to the present invention produces a constant outflow angle over the entire periphery, and substantially circumferentially symmetrical inlet conditions are passed onto the first compressor stage. This leads to an improved stability and an enhanced efficiency of the compressor.

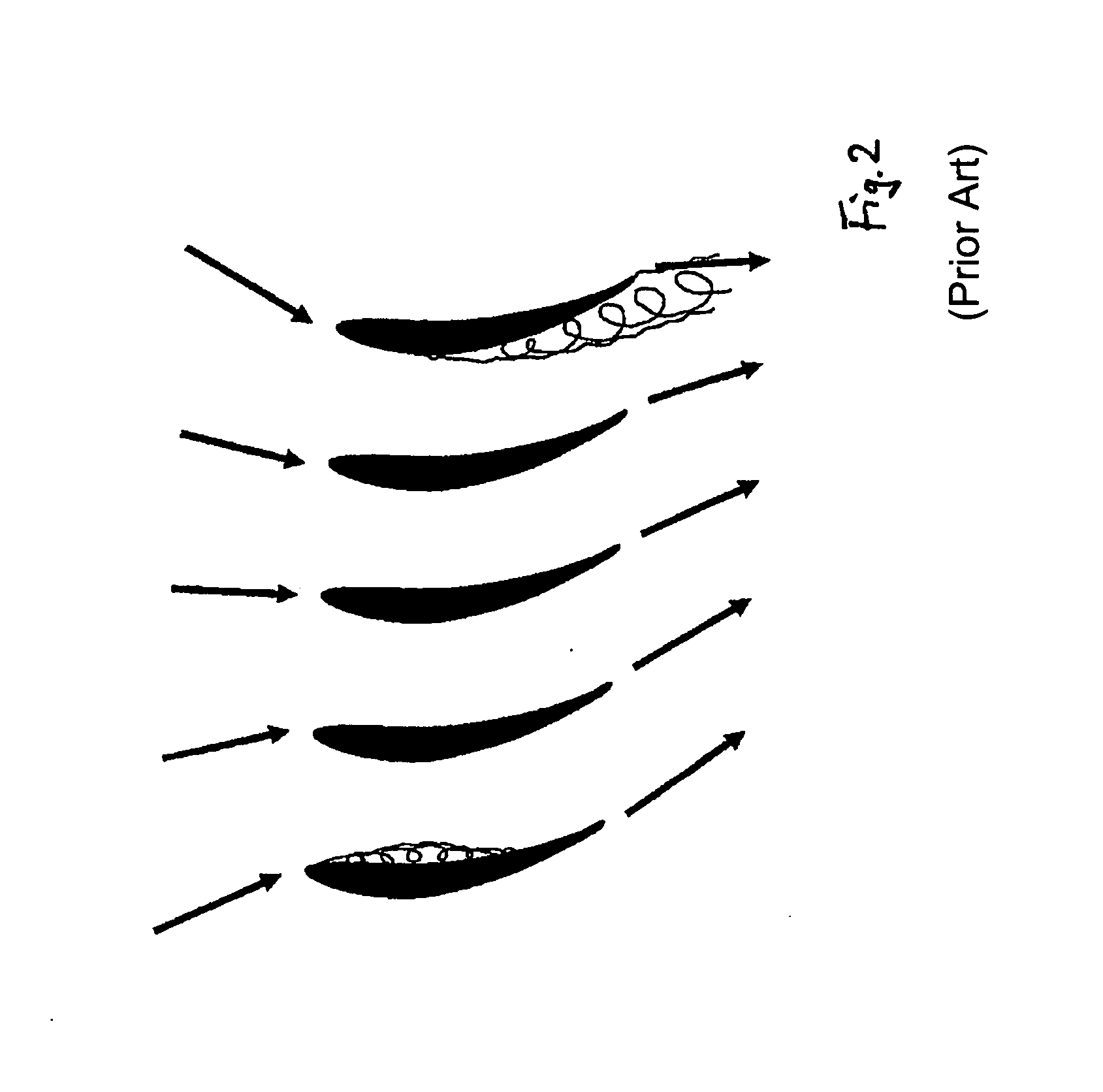

FIG. 2 shows a schematic representation of a developed view of an inlet guide baffle according to the related art, having a circumferentially asymmetrical incident flow that is caused by an asymmetric air inlet. Here, the extrem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com