Stack type heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Hereinafter, embodiments of the present invention will be described with reference to the drawings.

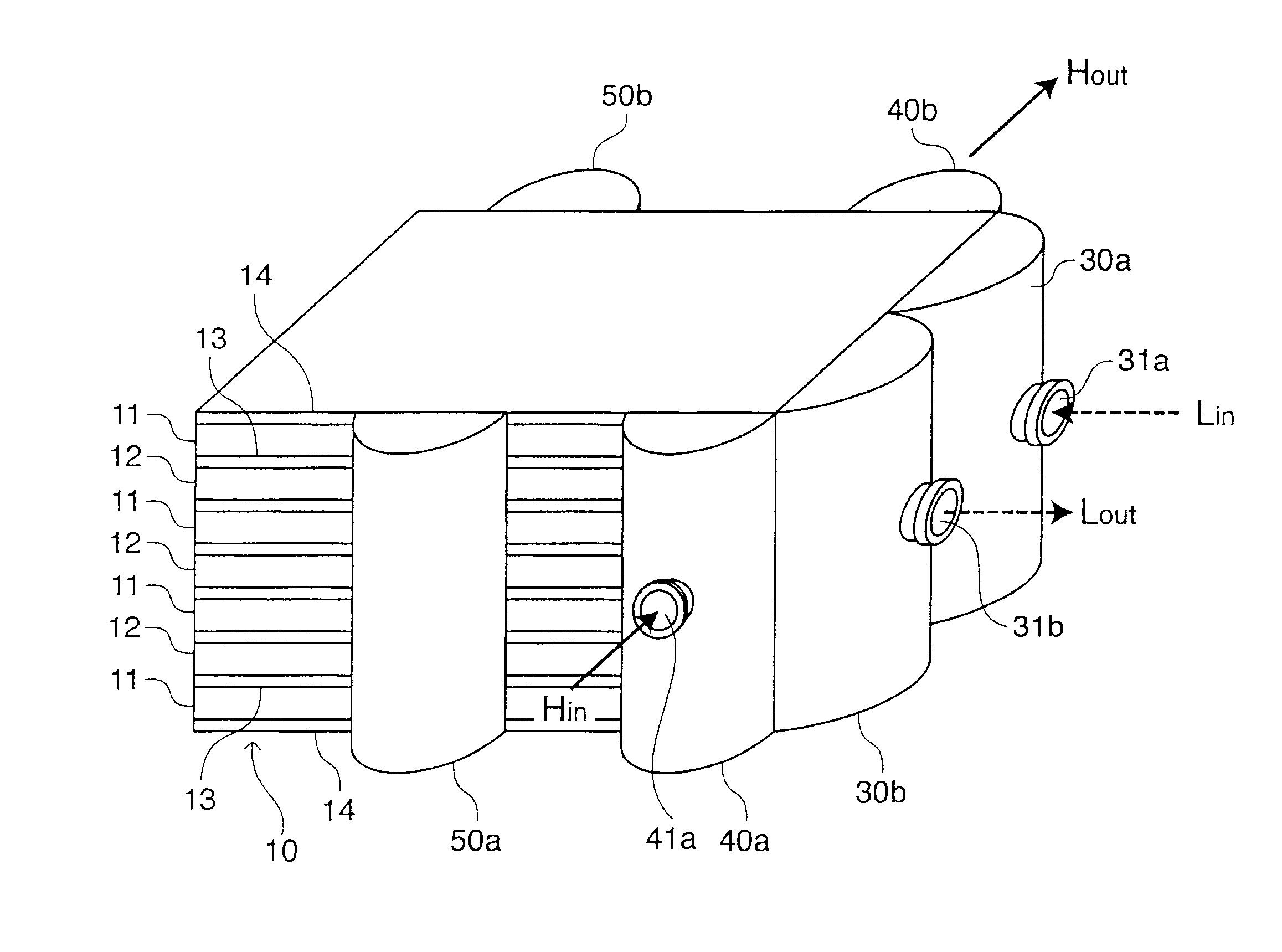

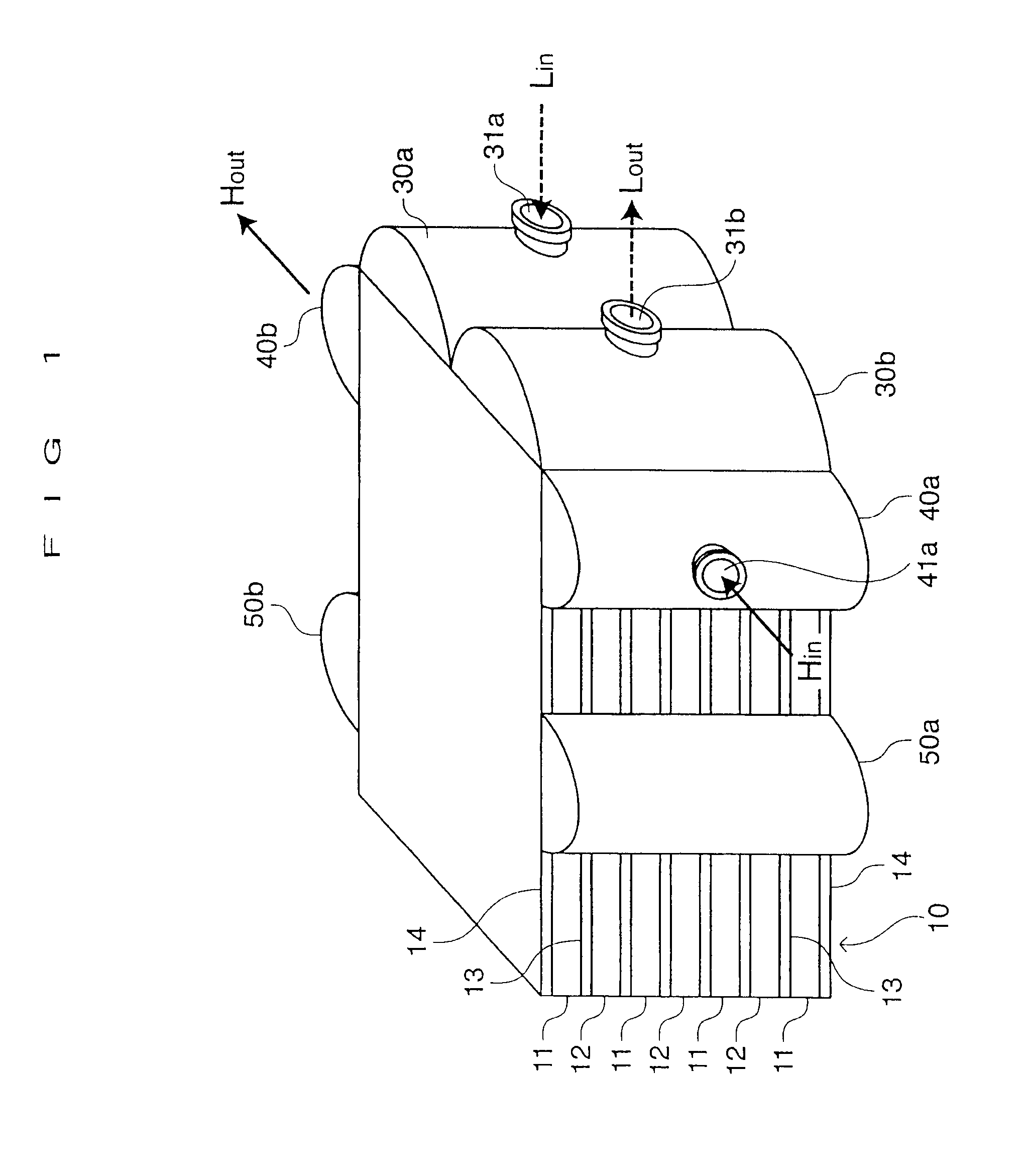

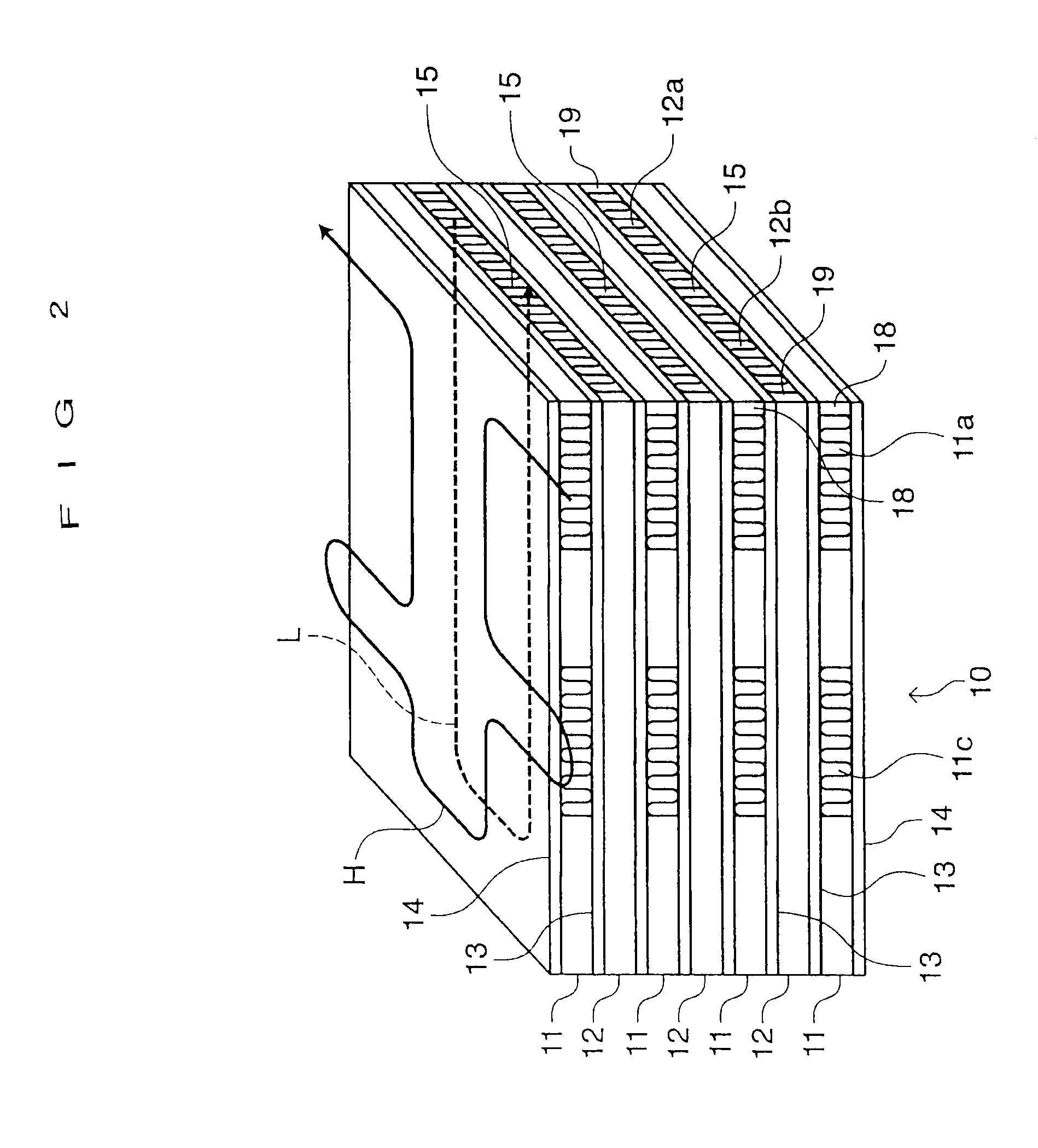

[0036]A stack type heat exchanger of this embodiment is used as an aircraft engine oil cooler, and as shown in FIGS. 1 and 2, has a rectangular cuboid stacked core 10 including a plate-fin type heat exchanger of a counterflow type. In the stacked core 10, layered hot fluid passages 11 including corrugated fins and layered cold fluid passage 12 including corrugated fins are alternately stacked. Partition plates 13 called tube plates are provided between the hot fluid passages 11 and the cold fluid passages 12, and both end faces in the stacking direction of the stacked core 10 are closed by end plates 14 called tube plates.

[0037]As shown in FIGS. 3 and 4, each of the hot fluid passages 11 and each of the cold fluid passages 12 are both of a U-turn type, and a partitioning member 15 which partitions its first half and its return path is provided in the center portion in the width d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com