Throating

a technology of adhesive tape and throating, which is applied in the field of throating, can solve the problems of affecting the work efficiency of workers, and affecting the effect of construction work, so as to facilitate construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be explained in detail below with reference to accompanying diagrams.

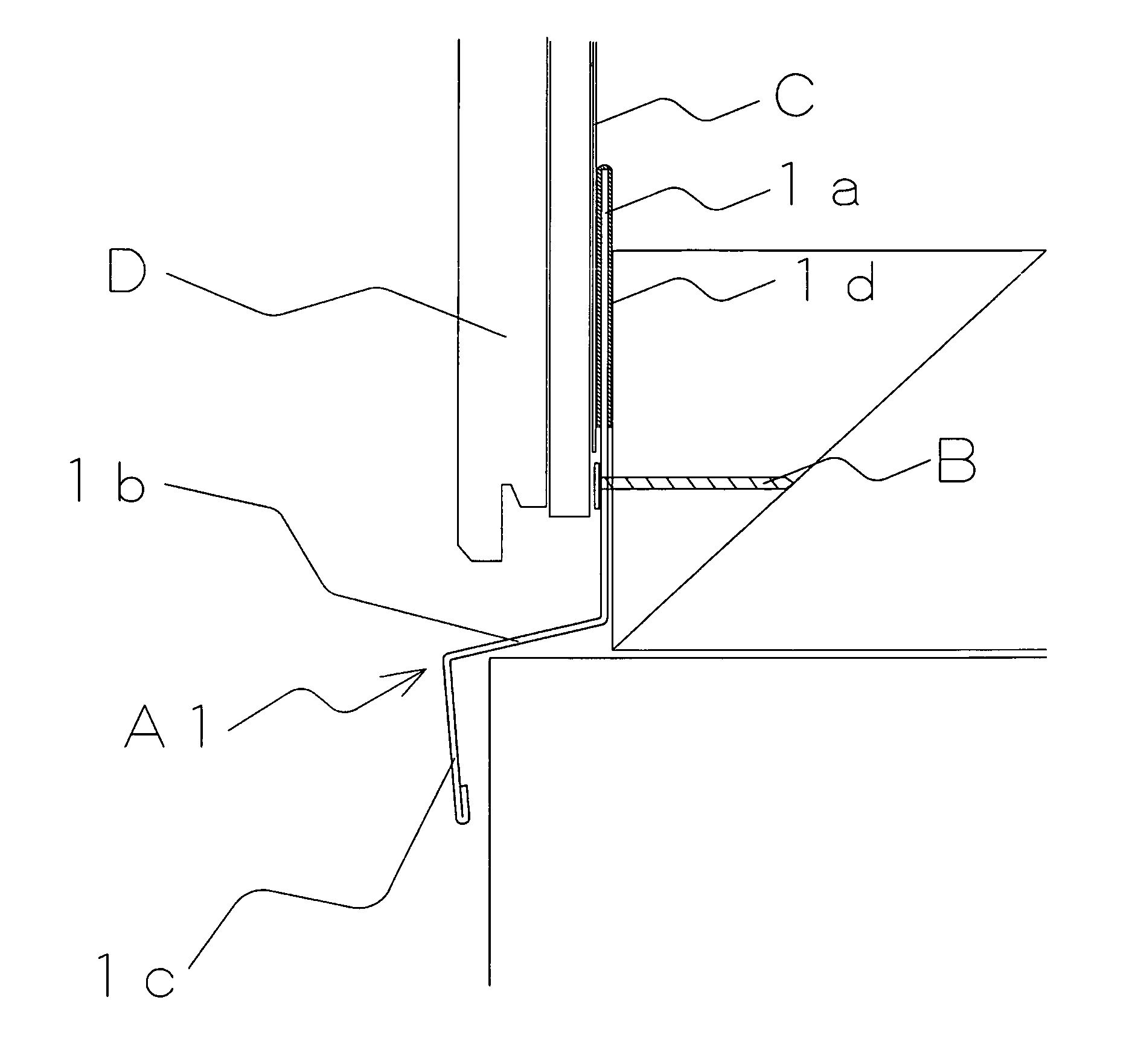

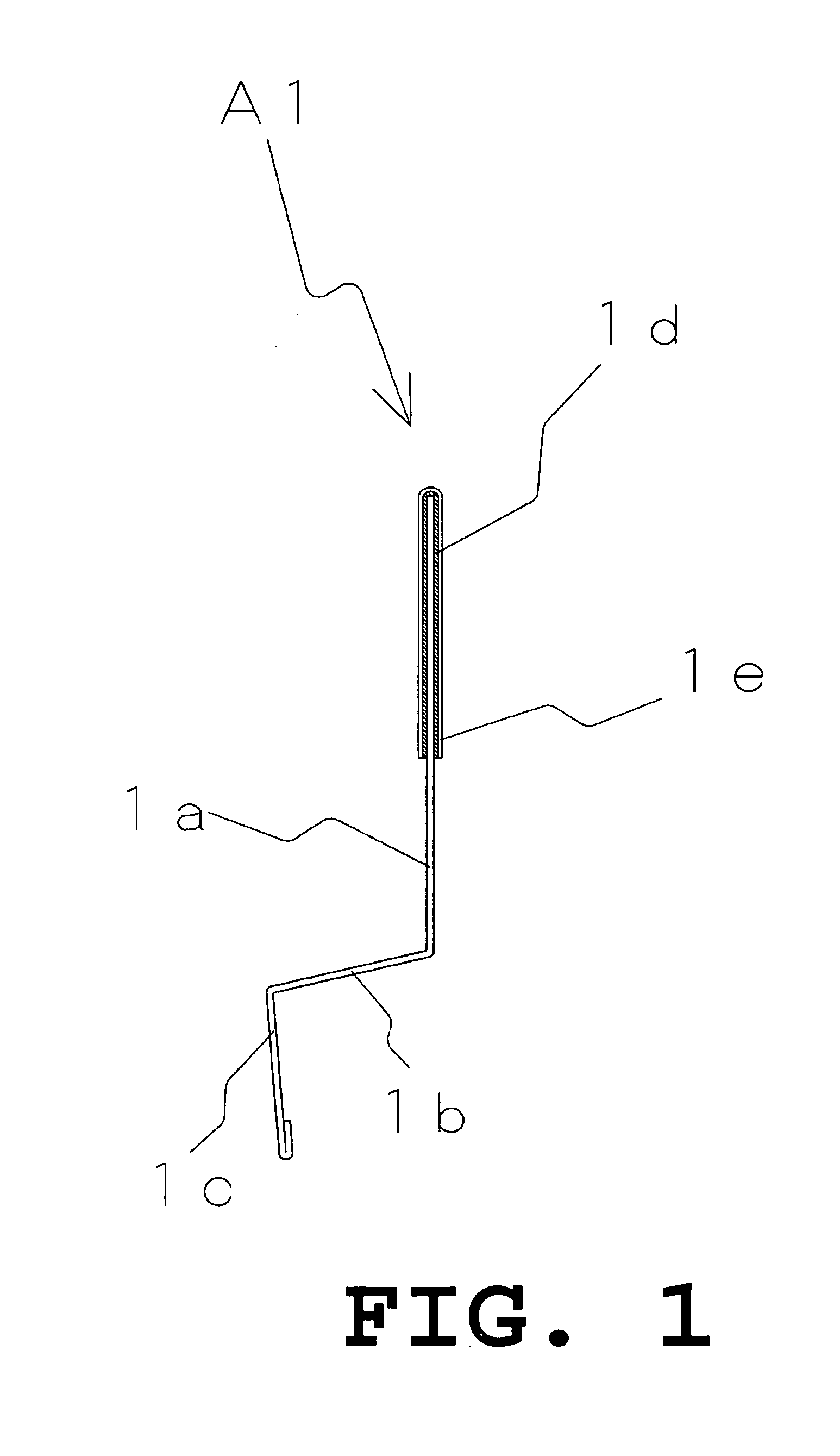

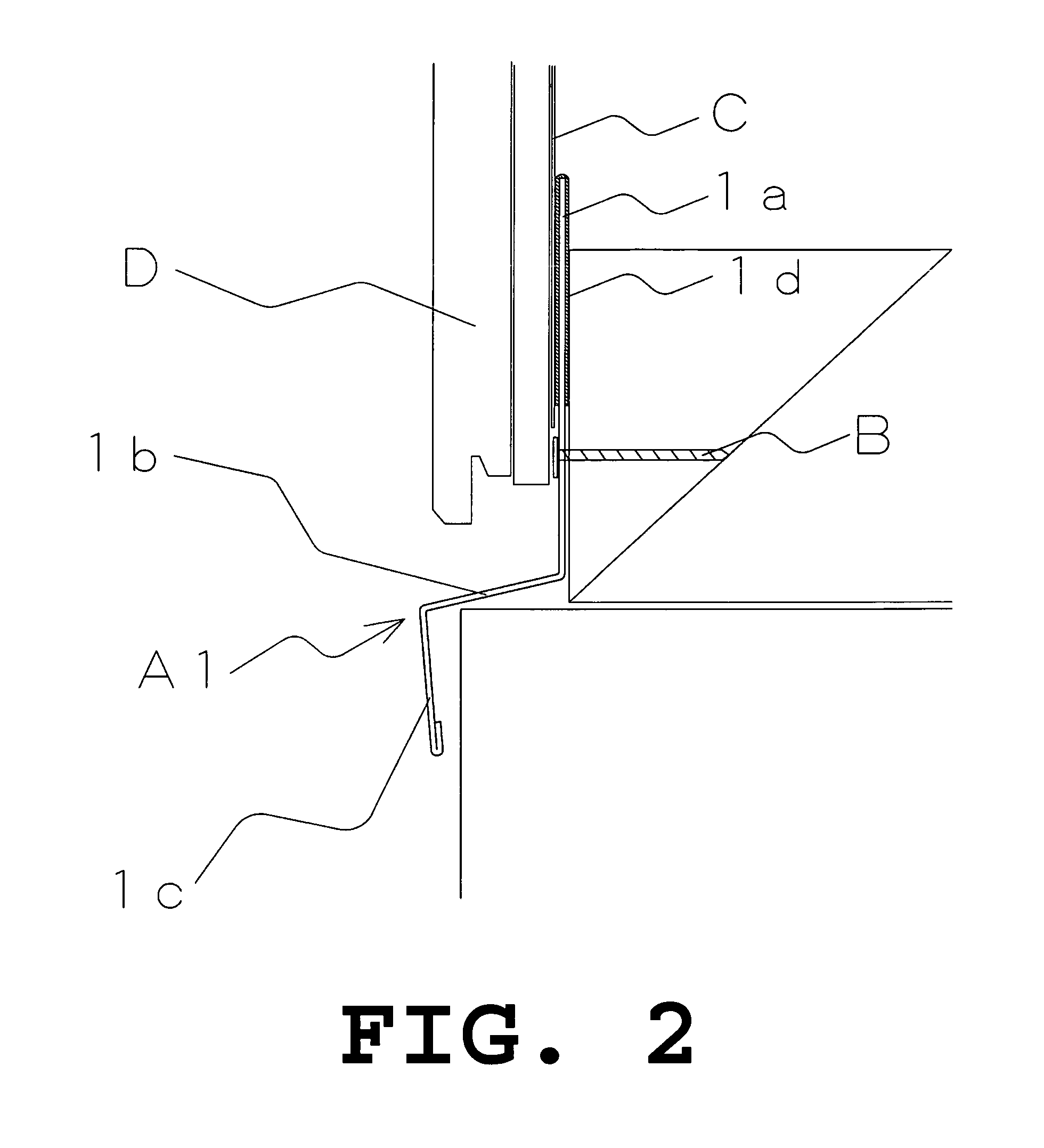

[0034]FIG. 1 is a right side-view diagram of an embodiment of a throating according to the present invention.

[0035]In a throating A1 illustrated in FIG. 1, which is manufactured by folding one Galvalume steel sheet, there are contiguously formed a rear plate part 1a fixed to a building frame, a throating plate part 1b bent obliquely downward and frontward at a lower end of the rear plate part 1a, and a front plate part 1c bent downward from the front end of the throating plate part 1b. More specifically, the rear plate part 1a is a flat plate part. The throating plate part 1b extends obliquely downward and frontward from the lower end of the rear plate part 1a. The front plate part 1c extends downward from the front end of the throating plate part 1b. On the front face, the top end portion and the rear face of the rear plate part 1a, an adhesive layer 1d, comprising an acrylic adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com