Apparatus and method for collection of wet concrete residue from dispensing element of concrete delivery vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The following discussion describes in detail one embodiment of the invention and several variations of that embodiment. This discussion should not be construed, however, as limiting the invention to those particular embodiments. Practitioners skilled in the art will recognize numerous other embodiments as well.

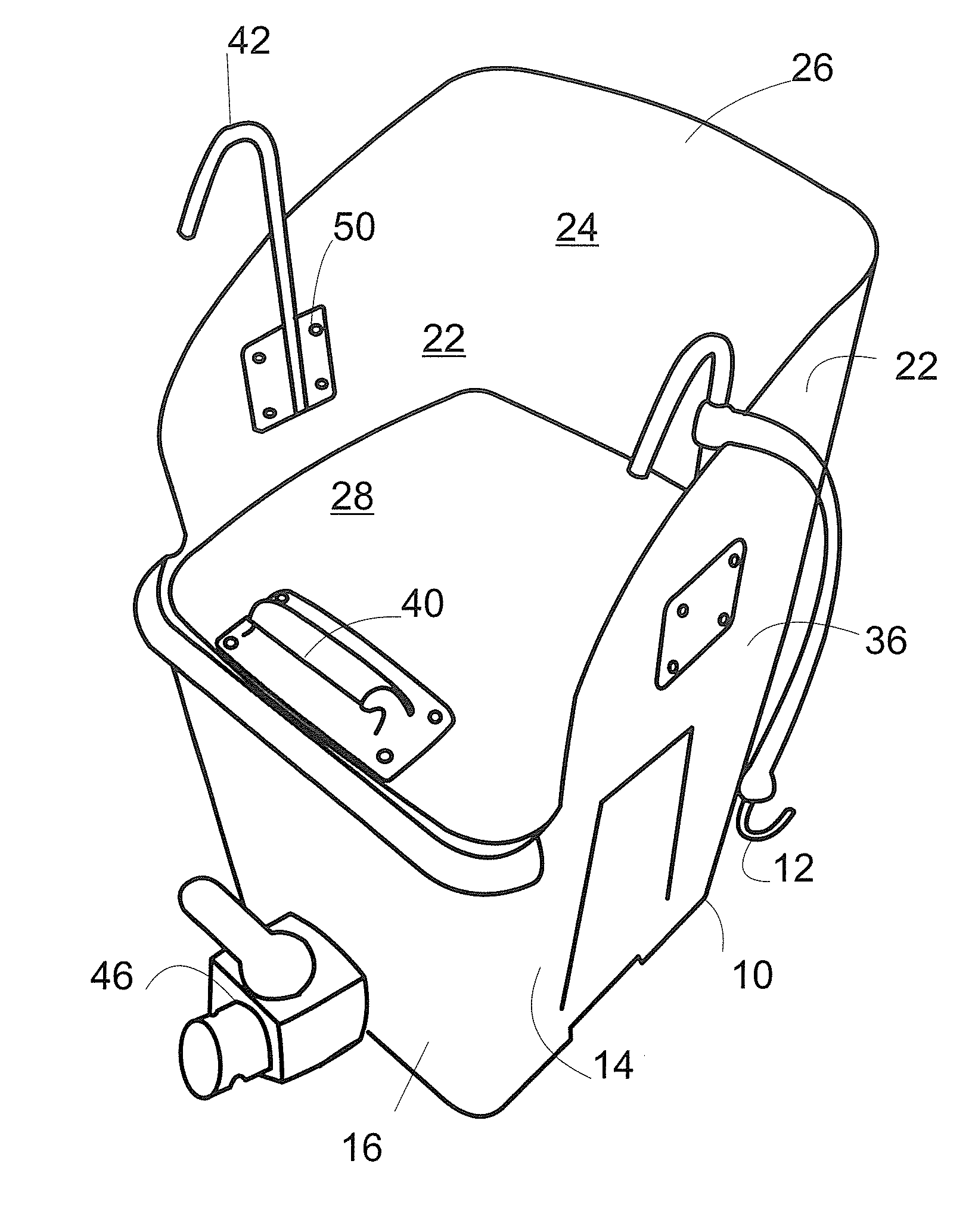

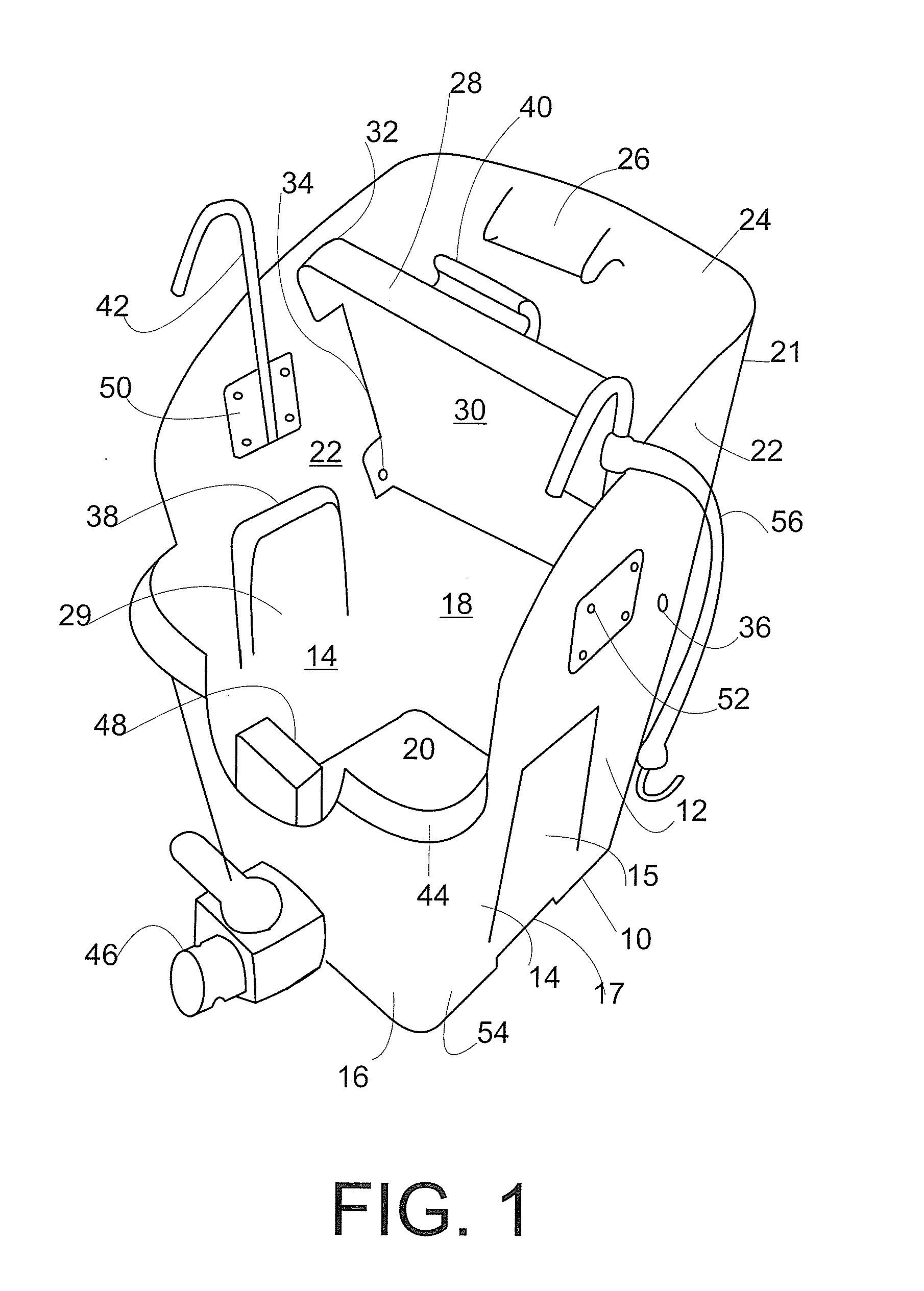

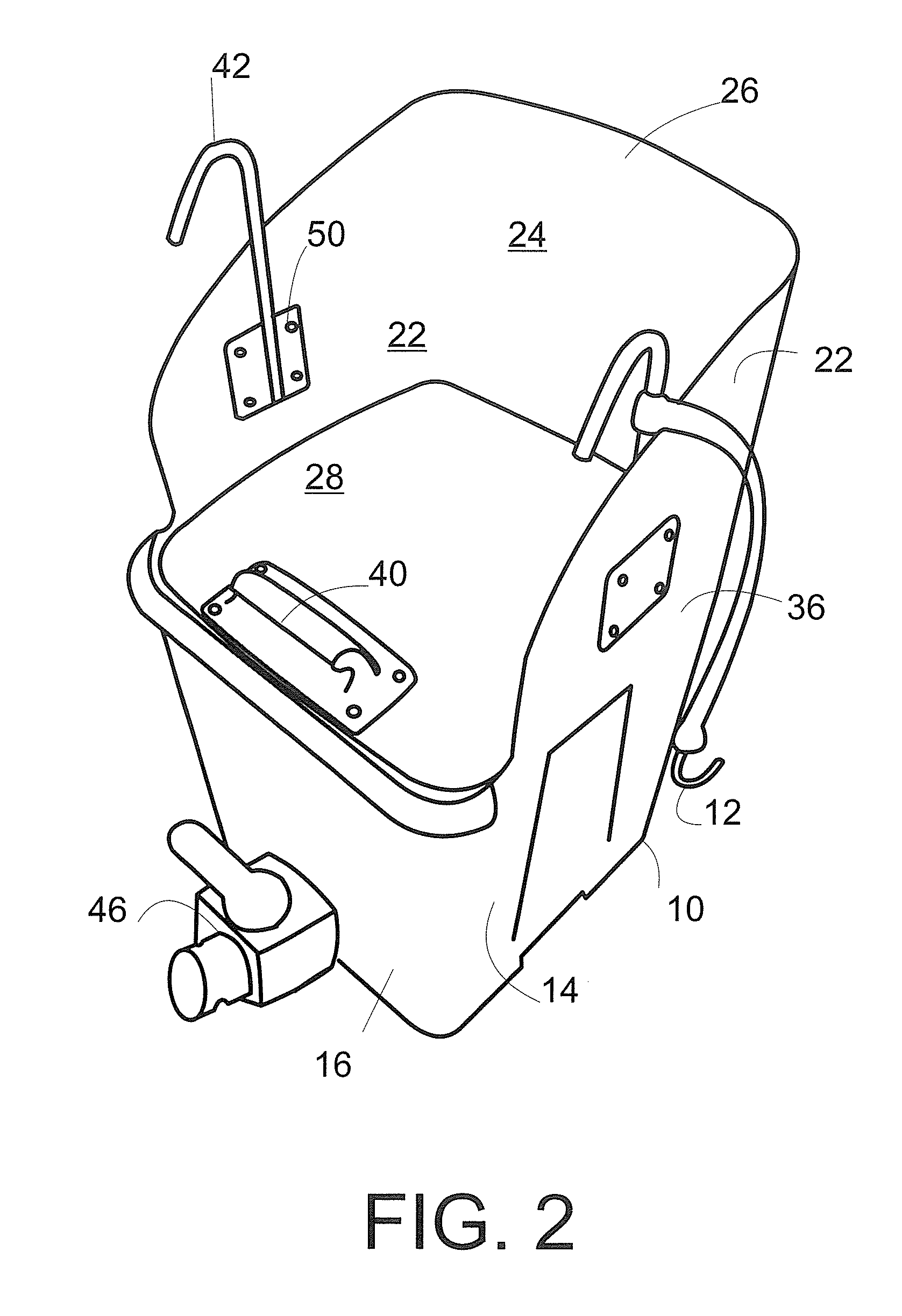

[0037]FIG. 1 is a partially exposed perspective view of an exemplary apparatus 10 for the collection of wet concrete residue that results, from rinsing of a dispensing element, such as a chute 60 that delivers concrete from a mixing drum 62 of a concrete delivery vehicle 64 (as best seen in FIG. 6). FIG. 1 shows the exemplary apparatus 10 with its containment cover 28 in an opened position. The apparatus 10 comprises a container body 12 that has side walls 14, a front wall 18, a back wall 18 and a bottom 20. The side walls 14 can preferably have indentations 15 formed therein for added strength, and also to adapt the apparatus 10 to be suspended on a carrying rack 66 on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com